5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform several vital functions. They are engineered to:

·Create a leak-proof seal.

·Direct hot and cold fluids into alternating channels.

·Prevent cross-contamination between fluids.

·Withstand extreme operational pressures and temperatures.

·Allow for easy equipment disassembly and maintenance.

The growing market underscores the importance of these components in modern industry.

| Metric | Value |

|---|---|

| Market Size (2024) | USD 6.13 billion |

| Projected Market Size (2033) | USD 10.82 billion |

| CAGR (2025-2033) | 6.8% |

Role 1: Creating a Primary Seal to Prevent External Leakage

The most fundamental role of a gasket is to create a robust seal. This seal prevents fluids from escaping the plate heat exchanger unit. A secure seal is the first line of defense for ensuring safety, efficiency, and cost-effectiveness in any operation.

Containing Process Fluids Securely

Gaskets form a tight barrier around the edge of each plate. This barrier effectively contains the process fluids within their designated flow paths. In the food and beverage industry, this function is critical for managing a wide variety of liquids. These fluids often include:

·Juices, including those with pulp

·Dairy products and beers

·Carbonated beverages and sodas

·Sports drinks containing salts

Proper containment ensures that these products remain pure and within the system until the thermal process is complete.

Preventing Hazardous Environmental Spills

Many industrial applications involve aggressive or hazardous chemicals. A failed seal in these environments can lead to dangerous spills. These incidents pose significant risks to personnel safety and can cause severe environmental damage. High-quality plate heat exchanger gaskets provide the reliability needed to handle corrosive or toxic substances, preventing catastrophic leaks and ensuring a safe operational workspace.

Minimizing Costly Product Loss

Note: Even a minor, persistent leak can result in substantial financial losses over time. The cumulative loss of valuable product or expensive treatment chemicals directly impacts profitability.

A dependable primary seal eliminates this waste. It ensures that every drop of product is processed, not lost. This function makes the gasket a small but powerful component for protecting a company's bottom line and maximizing operational efficiency.

Role 2: Directing Fluid Flow for Maximum Efficiency

Beyond sealing, gaskets play a crucial role in guiding fluids through the heat exchanger. This channeling function is fundamental to the unit's thermal efficiency. The gasket’s design ensures that hot and cold media flow correctly through their designated paths, maximizing energy transfer.

The Gasket's Channeling Function

Gaskets are engineered with two distinct sections: a field gasket and a ring gasket. The field gasket forms the outer seal of the plate. The ring gaskets seal the ports, directing fluid into or out of the flow channels. This arrangement dictates the flow path. It forces one fluid to flow across the plate while allowing the second fluid to bypass that plate and move to the next one. This precise direction is what creates the alternating pattern of hot and cold channels.

Enabling Counter-Current Flow

The most efficient thermal exchange occurs when fluids flow in opposite directions. This is known as counter-current flow. Plate heat exchanger gaskets make this possible by creating a specific flow pattern. One gasket directs the hot fluid to flow downwards across a plate. The gasket on the adjacent plate directs the cold fluid to flow upwards. This opposing movement maintains a significant temperature difference along the entire length of the plate, which is essential for effective heat transfer.

Optimizing Thermal Performance

The combination of directed flow and plate design leads to exceptional performance. Gasketed plate heat exchangers can achieve heat transfer coefficients (U-values) between 3,000 and 7,000 W/m²·K in liquid-to-liquid tasks.

This high efficiency results from the turbulent flow created by the plates' chevron patterns. While the plates create turbulence, the gaskets ensure the fluid enters these channels correctly. By enabling counter-current flow and preventing fluid bypass, gaskets help the system reach its maximum thermal potential, saving energy and reducing operational costs.

Role 3: Separating Fluids to Prevent Cross-Contamination

A critical safety function of gaskets is to keep the two process fluids completely separate. This separation prevents internal mixing, which could compromise product quality, create safety hazards, or damage equipment. Modern gasket design provides a robust solution to this challenge.

The Double-Gasket Barrier System

Advanced plate heat exchanger gaskets feature a double-gasket design at the ports. This system creates two separate seals around each fluid channel. A small, vented gap exists between these two seals. This space opens to the atmosphere, forming a physical barrier that makes it virtually impossible for the two fluids to mix internally, even if one of the seals fails.

Protecting Product Purity and Quality

In industries like pharmaceuticals and food production, preventing contamination is non-negotiable. The slightest impurity can ruin a batch or pose a health risk. Regulatory bodies enforce strict standards for product purity.

·Guidelines from the FDA and EMEA require manufacturers to identify any degradation products that exceed 0.1%.

·Products must be free from contaminants like bacteria and endotoxins to meet GMP (Good Manufacturing Practices) regulations.

·International standards like ICH Q3 and Q6 set firm limits on impurities to ensure drug safety and efficacy.

The double-gasket system directly supports compliance by ensuring process fluids remain isolated.

Avoiding Dangerous Chemical Reactions

Safety Tip: Mixing incompatible chemicals, such as a strong acid and a caustic solution, can trigger violent exothermic reactions, release toxic gases, or cause rapid pressure increases.

The separation function of the gasket is a primary safety feature in chemical processing. It prevents accidental mixing of reactive substances, protecting personnel from dangerous chemical events and safeguarding the integrity of the entire system.

Incorporating Leak Detection Features

The vented space in the double-gasket system also serves as a built-in leak detector. Should an inner gasket degrade or fail, the process fluid will escape through this channel to the outside of the unit. This creates a visible leak that operators can immediately spot. This early warning allows maintenance teams to address the issue before the second gasket is compromised, preventing a major spill or forced shutdown.

Role 4: The Critical Role of Plate Heat Exchanger Gaskets in Withstanding Operational Stress

Plate heat exchanger gaskets must endure constant physical and chemical stress. Their ability to withstand harsh operating conditions is essential for the long-term reliability and safety of the heat exchanger. Engineers design these components to resist pressure, temperature, and chemical attack.

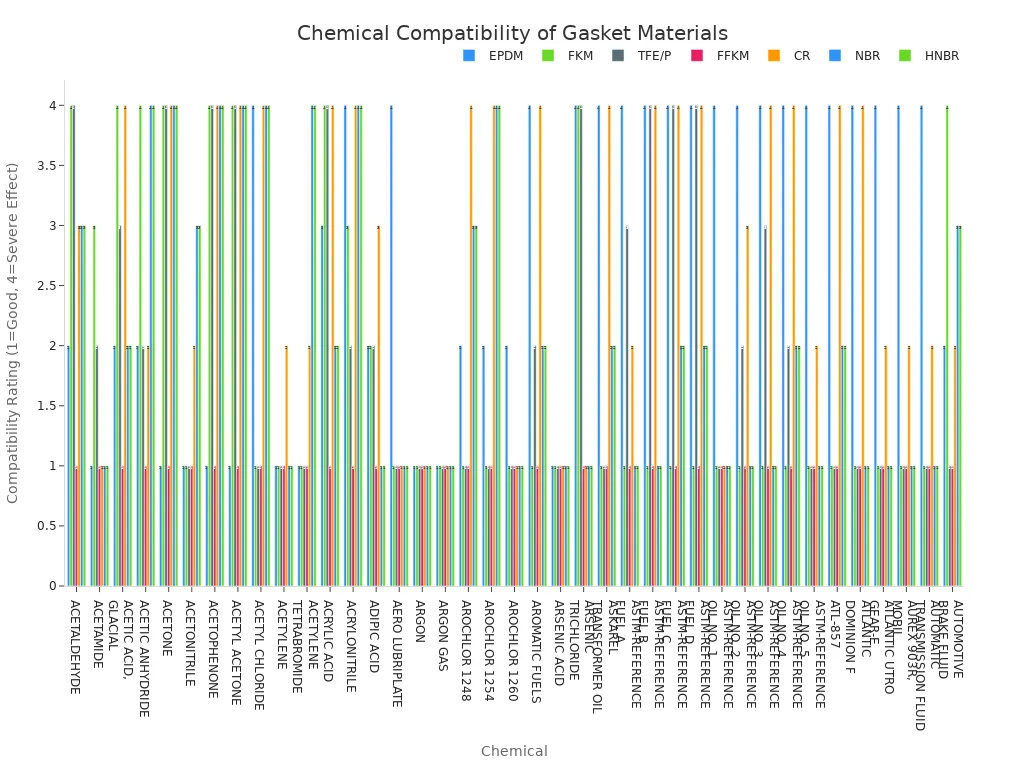

Material Selection for Demanding Conditions

Choosing the correct gasket material is a critical engineering decision. The material must be compatible with the process fluids to prevent chemical degradation. Different elastomers offer varying levels of resistance to certain chemicals. For example, EPDM performs well with water and steam, while FKM (Viton) is better suited for oils and fuels. Chemical compatibility charts help engineers select the optimal material for any given application, ensuring a long service life.

Maintaining Integrity Under High Pressure

Gaskets must maintain a perfect seal even when subjected to significant internal pressure. The force exerted by the fluids pushes against the gasket surface. A well-designed gasket resists deformation and extrusion under this load. In applications like HVAC systems, gasketed units often operate at pressures up to 25 bar. The gasket's structural integrity prevents leaks and ensures the system operates safely within its specified pressure limits.

Resisting Degradation from Extreme Temperatures

Temperature fluctuations pose a major challenge to gasket materials. Each material has a specific operating temperature range. For instance:

·EPDM Rubber: -40°C to +120°C (-40°F to +248°F)

·Viton Rubber: -25°C to +250°C (-13°F to +482°F)

Thermal cycling, which involves repeated heating and cooling, causes gasket materials to expand and contract. This repeated stress leads to material degradation, cracking, and eventual failure.

Operating outside a material's designated range or subjecting it to rapid temperature changes compromises its elasticity. This degradation weakens the seal, increasing the risk of failure and system downtime.

Role 5: Enabling Disassembly for Maintenance and Cleaning

Gaskets are designed not just to seal but also to be removed. This feature is fundamental for the long-term serviceability of a plate heat exchanger. It allows technicians to open the unit for essential inspection, cleaning, and component replacement.

Facilitating Routine Equipment Inspections

Regular inspections are crucial for preventive maintenance. Gaskets that allow for easy disassembly give operators direct access to the plates. This access enables them to check for signs of wear and potential failure. Key visual indicators include:

·Brittleness: The gasket feels stiff and has lost its elasticity.

·Deformation: The seal appears flattened or has taken a permanent set.

·Cracks or Tears: Visible breaks on the gasket surface.

·Extrusion: The gasket material looks frayed or is pushed out of its groove.

Early detection of these issues prevents unexpected downtime and catastrophic leaks.

Comparing Clip-On and Glued Gasket Designs

Manufacturers offer two primary gasket attachment methods: clip-on and glued. Clip-on gaskets attach to plates with built-in fasteners, allowing for rapid replacement with minimal downtime. This design is ideal for industries like dairy and pharmaceuticals that require frequent sanitation. Glued gaskets use an adhesive to create a very secure bond. While they provide an excellent seal, their replacement is more labor-intensive. The choice depends on the application's specific maintenance requirements.

Simplifying Plate Cleaning and Replacement

While Clean-in-Place (CIP) systems are effective, some fouling requires manual cleaning. The ability to disassemble the unit allows technicians to clean each plate individually. This process ensures the removal of stubborn residue that automated systems might miss. Replacing a damaged plate or a full set of gaskets also becomes a straightforward task. Technicians can perform the job on-site with basic tools like wrenches and solvents for removing old adhesive.

Extending Overall Equipment Lifespan

Proactive maintenance is significantly less expensive than repairing avoidable damage. Regular inspections and timely gasket replacement prevent costly unscheduled shutdowns and product loss, directly improving profitability.

A well-maintained gasket helps a heat exchanger operate efficiently and safely. With proper care, gaskets can last between three to ten years. By enabling easy service, the gasket's design plays a direct role in maximizing the equipment's operational life and lowering the total cost of ownership.

Plate heat exchanger gaskets are multi-functional components essential for operational integrity. Their performance relies on five fundamental roles:

·Sealing to prevent leaks

·Directing fluid for efficiency

·Separating fluids to avoid contamination

·Withstanding operational stress

·Enabling easy maintenance

Proper gasket selection and care are critical for ensuring system safety, efficiency, and reliability.

FAQ

How often should you replace PHE gaskets?

Gaskets typically last three to ten years. Their lifespan depends on operating conditions like temperature, pressure, and fluid type. Regular inspections help determine the exact replacement schedule.

What are the signs of a failing gasket?

Technicians look for visible signs of wear. These signs include brittleness, cracks, deformation, or material being pushed out of its groove. Early detection prevents major leaks. ⚠️

Is a clip-on or glued gasket better?

The choice depends on maintenance needs. Clip-on gaskets allow for fast replacement. Glued gaskets offer a very secure bond but require more labor to replace during service.