A complete list of top industries using GPHE heat exchangers in 2026

Here’s a quick look at the top industries using GPHE heat exchangers in 2026:

Food & Beverage

HVAC & Building Services

Chemical Processing

Power Generation

Oil & Gas

Pharmaceuticals & Biotechnology

Marine Engineering

Pulp & Paper

Refrigeration Systems

Shanghai Heat Transfer leads the way with its Gasketed Plate Heat Exchanger, trusted for reliability and innovation. These solutions help companies reach energy efficiency goals and support sustainability.

Check out how recent advances make these exchangers even better:

Technological Innovations

Sustainability Goals

Energy Efficiency

Advanced gaskets, improved plates, less downtime

Eco-friendly, recyclable products

Crucial for sustainability targets

Food & Beverage Industry

The food and beverage industry relies on safe, efficient, and reliable processes. Shanghai Heat Transfer brings years of expertise to this sector, helping companies meet strict food safety standards and optimize every step of production. Gasketed plate heat exchangers play a huge role here, especially in dairy and beverage processing.

Pasteurization with Gasketed Plate Heat Exchangers

Pasteurization is all about heating products to kill harmful bacteria while keeping flavors and nutrients intact. Gasketed plate heat exchangers make this process fast and energy-efficient. Their design allows for precise temperature control, which is key for milk, juices, and other sensitive products. Shanghai Heat Transfer’s solutions help producers achieve consistent results, reduce energy use, and meet food safety regulations.

Product Cooling Applications

After pasteurization, products need to cool down quickly. Gasketed plate heat exchangers handle this job with ease. They transfer heat rapidly, so products reach safe storage temperatures in no time. This not only protects quality but also saves energy. Shanghai Heat Transfer’s gasketed plate heat exchangers are easy to clean, which means less downtime and more productivity.

You’ll find gasketed plate heat exchangers in many segments of the food and beverage industry, such as:

Dairy

Biotech

Pharmaceutical

Home and personal care

Other applications

If you want to boost food safety, cut energy costs, and streamline your process, Shanghai Heat Transfer’s gasketed plate heat exchangers are the smart choice.

HVAC & Building Services

Heating, ventilation, and air conditioning (HVAC) systems keep buildings comfortable all year. These systems use a lot of energy, especially for heating and cooling. Gasketed plate heat exchangers from Shanghai Heat Transfer help connect chillers, boilers, and cooling towers. This connection boosts efficiency and makes the system work better.

Energy Efficiency in HVAC Systems

Energy efficiency matters more than ever. Buildings use about 40% of global energy, and heating and cooling take up 60% of that. When you add a GPHE heat exchanger to your system, you can cut energy use and lower carbon emissions. Some buildings have reduced their energy use by half with smart upgrades. GPHE heat exchangers transfer heat quickly, so less energy gets wasted. They also have a compact design, which means you save space and get more out of your system.

Want to see how GPHE heat exchangers help with sustainability?

Energy Consumption

Potential Reduction

Transition from Gas

40% of global energy use

Up to 50% less energy and carbon emissions

Clean energy can replace gas

Shanghai Heat Transfer offers solutions that fit any building. Their products help you reach your efficiency goals and support green building standards.

District Heating and Cooling

District heating and cooling systems serve many buildings at once. GPHE heat exchangers play a key role in these systems. They move heat between sources and buildings with high efficiency. You can adjust the system easily by adding or removing plates. This flexibility means you get the right amount of heating or cooling every time. Shanghai Heat Transfer’s GPHE heat exchangers make district systems reliable and easy to maintain. If you want a system that saves energy and works smoothly, their products are a smart choice.

Chemical Processing

Chemical plants face tough challenges every day. High temperatures, aggressive chemicals, and strict safety rules make reliable equipment a must. Shanghai Heat Transfer’s Gasketed Plate Heat Exchanger steps up to the plate in these environments. You get a solution that’s built to last and easy to maintain.

Gasketed Plate Heat Exchangers in Chemical Reactions

Chemical reactions often need precise temperature control. GPHE heat exchangers help keep things steady, so reactions happen safely and efficiently. The unique plate design creates turbulence, which boosts heat transfer and helps save energy. You can add or remove plates to match your plant’s needs. This flexibility means you don’t have to replace the whole system when your process changes. Shanghai Heat Transfer offers custom solutions for chemical plants, making sure you get the right fit every time.

Tip: A well-chosen GPHE can cut energy costs and improve product quality.

Corrosive Fluid Handling

Handling corrosive fluids is a big deal in chemical processing. Not every heat exchanger can take the punishment. Shanghai Heat Transfer uses advanced materials like stainless steel, titanium, and Diabon to tackle harsh chemicals. Diabon GPHEs, for example, handle acids and electrolytes at temperatures up to 390°F. Here’s a quick look at how different materials stand up to tough fluids:

Material Type | Corrosive Fluids Handled | Temperature Limit |

|---|---|---|

Diabon GPHEs | Hydrochloric acid, Sulphuric acid, Hydrofluoric acid, Phosphoric acid, Pickling acids, Electrolytes, Mixed acids, Chlorinated hydrocarbons, Aluminium chloride | Up to 390°F |

Shanghai Heat Transfer’s team can help you pick the best option for your plant. If you want durability and top performance, their gasketed plate heat exchangers are the way to go.

Power Generation

Power plants need to run smoothly and save as much energy as possible. That’s where the gphe heat exchanger comes in. This technology has changed the way power stations handle heat. It helps plants recover more energy and use it wisely.

Cooling & Heat Recovery

Cooling is a big deal in power generation. Hot water and steam need to cool down before they can be reused or released. The gphe heat exchanger makes this process fast and efficient. It has a compact design, so it fits easily into crowded plant spaces. The special plates inside boost heat transfer, which means less energy gets wasted. Plants can recover heat from one part of the process and use it somewhere else. This saves money and helps the environment.

High heat transfer efficiency means better energy recovery.

Compact size saves valuable space in the plant.

Flexible design adapts to changing needs and loads.

Shanghai Heat Transfer offers gphe heat exchanger solutions that work for all types of power plants. Their products handle tough jobs and keep running with little downtime.

GPHE Heat Exchanger Integration

Adding a gphe heat exchanger to your power plant is simple. You can scale up or down by adding or removing plates. This makes it easy to match your plant’s needs as they change. Shanghai Heat Transfer’s team helps you pick the right setup and supports you every step of the way. Their experience means you get a solution that fits your plant and boosts efficiency. If you want to cut costs and meet energy goals, a gphe heat exchanger from Shanghai Heat Transfer is a smart choice.

Oil & Gas Industry

The oil and gas industry faces big challenges with heat management. Every day, plants deal with high temperatures, tough chemicals, and strict safety rules. A lot of energy gets lost as waste. That’s where waste heat recovery comes in. Instead of letting heat escape, companies can capture it and use it again. This process saves money and helps the planet.

Heat Recovery Applications

Waste heat recovery is a game changer for oil and gas. Refineries and processing plants create a lot of waste heat during operations. If you let that heat go, you waste energy and money. Gasketed Plate Heat Exchangers from Shanghai Heat Transfer help capture this waste heat. They transfer it to other parts of the process, like preheating crude oil or generating steam. This means less waste and more savings. Shanghai Heat Transfer’s solutions work well in harsh environments. Their products use strong materials that stand up to tough jobs.

Did you know? Using waste heat recovery can cut fuel costs and lower emissions. It’s a smart move for any plant.

Thermal Management with GPHE

Thermal management keeps oil and gas systems running safely. Too much heat can damage equipment or slow down production. GPHE heat exchangers control temperatures and reduce waste. They move heat where it’s needed and keep everything balanced. Shanghai Heat Transfer offers engineering support for custom setups. Their team helps you pick the right materials and design for your plant. If you want better energy efficiency and less waste, their GPHE heat exchangers are a solid choice.

Benefit | Result |

|---|---|

Less waste | Lower costs |

Better heat control | Safer operations |

Flexible design | Easy upgrades |

Pharmaceuticals & Biotechnology

The pharmaceutical and biotech world demands strict control over every process. Even a small temperature change can affect product quality or safety. That’s why many companies trust Shanghai Heat Transfer’s Gasketed Plate Heat Exchanger. These units help keep everything clean, safe, and running smoothly.

Sterile Process Temperature Control

Sterility is a must in this industry. GPHE heat exchangers make it easy to control temperatures during sensitive steps like fermentation or purified water production. Their hygienic design meets the highest cleanliness standards. You can count on them to help you pass audits and meet regulations. Here’s a quick look at where GPHE heat exchangers make a difference:

Application Type | Description |

|---|---|

Purified Water Systems | Essential for maintaining water quality and temperature control. |

Fermentation | Critical for controlling the temperature during biological processes. |

Cooling Circuits | Used to manage heat removal in various processes. |

Shanghai Heat Transfer offers customizable setups. You can adjust the number of plates to match your process. This flexibility means you get the right fit every time.

Clean-in-Place (CIP) Systems

Keeping equipment clean is just as important as keeping it cool. GPHE heat exchangers from Shanghai Heat Transfer are easy to clean and maintain. They support automated CIP systems, which save time and reduce downtime. Integrity testing is built in, so you get reliable documentation for every audit. Here’s what sets these heat exchangers apart:

Hygienic design for easy cleaning

Automated systems for accurate records

Customizable configurations for any process

If you want peace of mind and top performance, Shanghai Heat Transfer’s GPHE heat exchangers are a smart choice for your pharmaceutical or biotech plant.

Marine Engineering

Marine engineering faces unique challenges. Space is tight, and equipment must handle tough conditions. That’s why many ships and offshore platforms now use Gasketed Plate Heat Exchangers (GPHEs) from Shanghai Heat Transfer. These units are compact, reliable, and built for the sea.

Engine Cooling Systems

Ship engines work hard and generate a lot of heat. If you don’t cool them properly, you risk breakdowns or even damage. GPHE heat exchangers step in to keep engine temperatures just right. Their compact design fits easily into crowded engine rooms. You don’t need to worry about finding extra space. Plus, these exchangers handle vacuum conditions and use strong materials like titanium. This makes them perfect for the harsh marine environment.

Did you know? The Royal Caribbean Group’s Legend of the Seas uses advanced GPHEs made from low-emission steel. These systems boost fuel and energy efficiency while helping ships meet decarbonization goals.

Shanghai Heat Transfer’s GPHEs offer:

Easy installation in tight spaces

Reliable cooling for engines

Durable materials for long life at sea

Freshwater Production

Freshwater is vital on ships and offshore platforms. GPHE heat exchangers help turn seawater into fresh water through desalination. Their efficient heat transfer speeds up the process and saves energy. The compact footprint means you can fit them almost anywhere, even on smaller vessels.

Shanghai Heat Transfer’s solutions keep operations running smoothly. Their products deliver the reliability and performance marine engineers trust, voyage after voyage.

Pulp & Paper Industry

The pulp and paper industry uses a lot of energy. Every step, from pulping to drying, needs careful temperature control. Gasketed plate heat exchangers (GPHEs) have become a game changer for mills looking to save energy and boost efficiency.

Process Water Heating

Heating process water is a big part of making paper. GPHEs help mills recover heat from hot wastewater, exhaust gas, and steam condensate. This means less steam is needed from the boiler, which cuts down on fuel use and costs. Here’s how GPHEs make a difference:

Recover heat from high-temperature wastewater and steam.

Warm up process fluids like slurry and water, so boilers work less.

Cool fluids to keep equipment running smoothly and protect product quality.

Shanghai Heat Transfer’s Gasketed Plate Heat Exchanger stands out in this area. The modular design lets mills adjust capacity as needed. The compact size saves space, and the easy-to-clean plates mean less downtime. If you want to lower your energy bills and keep your process steady, this is the way to go.

Chemical Recovery Systems

Chemical recovery is another key part of pulp and paper production. Mills reuse chemicals to save money and reduce waste. GPHEs help by transferring heat efficiently during the recovery process. This keeps temperatures just right for chemical reactions and helps mills meet strict environmental rules.

Shanghai Heat Transfer works closely with pulp mills to design custom solutions. Their team understands the unique challenges of the industry. With their expertise, mills can optimize every step, from water heating to chemical recovery. That means more savings, better performance, and a greener operation.

Refrigeration Systems

Refrigeration systems keep our food fresh, medicines safe, and warehouses cool. GPHE heat exchangers are a top choice for these jobs because they work well in many settings. You can find them in food preservation, pharmaceutical storage, and large-scale cold storage. Their flexible design fits both small and big systems, making them a cost-effective solution for many businesses.

Condensers and Evaporators

GPHE heat exchangers play a key role in condensers and evaporators. They help move heat quickly and keep temperatures steady. This means better heat transfer efficiency and less energy wasted. When you use a GPHE, you get an energy recovery system that supports enhanced waste heat recuperation. This helps lower the environmental impact of your operations. Shanghai Heat Transfer offers heating and cooling solutions that fit tight spaces and tough demands. Their products are easy to clean and maintain, which leads to minimal downtime.

GPHE Heat Exchanger Benefits

Shanghai Heat Transfer stands out for its expertise in refrigeration. Their team suggests checking for pressure drop changes and keeping spare plate packs ready. This helps avoid problems and ensures minimal downtime. Regular maintenance and quick leak repairs keep your system running smoothly. You can even reuse old heat exchangers for new tasks, which means a lower total cost of ownership. With Shanghai Heat Transfer, you get reliable performance and a cost-effective solution for all your refrigeration needs.

GPHE heat exchangers are everywhere now, from food plants to ships. Their use is growing fast:

The market is set to grow at over 6% CAGR from 2024 to 2026.

More industries want energy efficiency testing and compact solutions.

Shanghai Heat Transfer leads with innovation and custom designs. Check out how these features support scalability and sustainability:

Feature | Contribution |

|---|---|

Efficiency | Higher heat transfer with less energy |

Modularity | Easy to upgrade and maintain |

Exciting new trends include better gasket materials, smart sensors, and eco-friendly designs. GPHE technology will keep getting better and greener.

FAQ

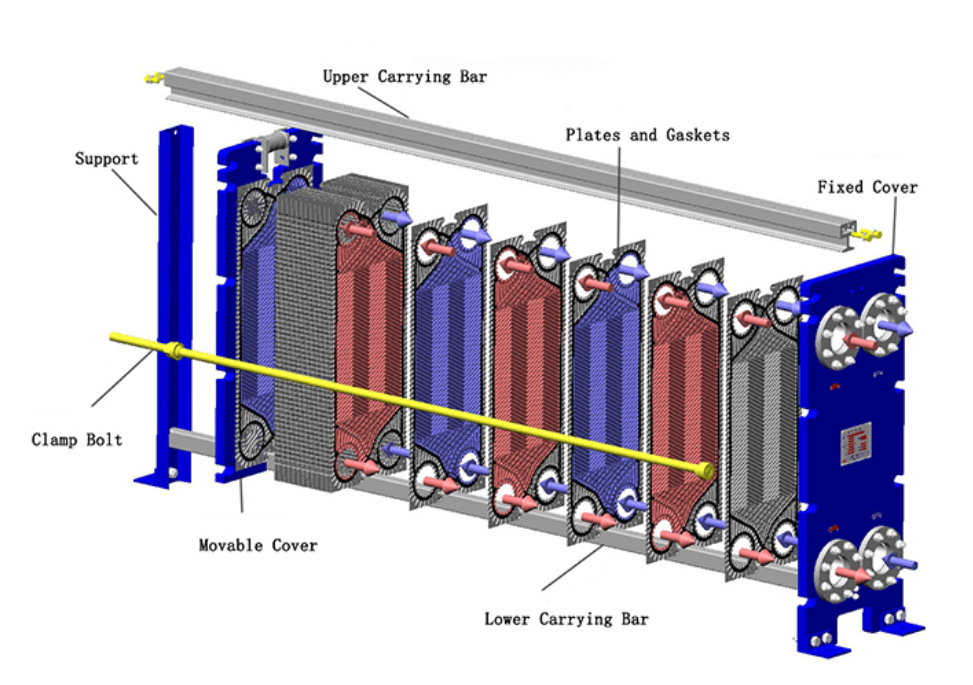

What makes a Gasketed Plate Heat Exchanger better than other types?

Shanghai Heat Transfer’s GPHE saves space, boosts energy efficiency, and is easy to clean. You can add or remove plates for quick upgrades.

Can I use one GPHE for different industries?

Yes! GPHEs from Shanghai Heat Transfer work in food, HVAC, chemical, and more. Their flexible design fits many processes.

How do I know which GPHE model is right for my plant?

Just ask the Shanghai Heat Transfer team. They help you pick the best model for your needs and offer expert support.