Best Gasketed Heat Exchanger Designs for Modern Factories

Factories in 2025 rely on advanced gasketed heat exchanger designs that deliver high efficiency, flexibility, and reliability. Modular plate heat exchangers, especially those with innovative features, now dominate industrial settings. The table below highlights the most widely used designs and their applications:

Heat Exchanger Type | Key Features | Applications |

|---|---|---|

Microchannel Heat Exchangers (MCHE) | Compact, high efficiency, less refrigerant usage | HVAC, automotive |

Plate Heat Exchangers (PHEs) | Modular design, easy maintenance, flexible capacity | HVAC, food processing, chemical processing |

Welded and Printed Circuit Designs | Robust, leak-proof, extreme environments | Oil & gas, chemical industries |

Shanghai Heat Transfer leads with solutions that combine advanced materials and modular engineering, helping factories achieve energy savings and long-term durability. Selecting the right gasketed heat exchanger supports operational goals and adapts to changing industrial needs.

Top Gasketed Heat Exchanger Designs

Plate and Frame Gasketed Heat Exchangers

Plate and frame gasketed heat exchangers remain the most popular choice for modern factories. Their design uses a series of corrugated plates, each sealed with a gasket, to create separate channels for hot and cold fluids. This arrangement allows for efficient heat transfer and easy maintenance. Factories value these exchangers for their adaptability and compact size. The following table highlights the defining features that make them suitable for industrial use:

Feature | Description |

|---|---|

Superior reliability | Enhanced reliability and energy efficiency through innovative designs like OmegaPort™ and FlexFlow™. |

Compact size | Small footprint due to CompactFrame™ design, making them suitable for space-constrained environments. |

Minimal fouling | CurveFlow™ plate distribution minimizes fouling, ensuring consistent performance. |

Easy installation and service | Five-point alignment system allows for hassle-free installation and maintenance. |

Environmental efficiency | Optimized production processes reduce environmental impact, aligning with modern sustainability goals. |

High thermal performance | Counter-current flow design maximizes heat transfer efficiency and minimizes temperature differences. |

Adaptability | Simple design allows for easy adjustments to meet changing process conditions. |

Factories often choose plate and frame gasketed heat exchangers for their high efficiency and low maintenance needs. These exchangers also offer lower installation costs and shorter downtime for maintenance compared to other designs. For example, they typically require only 1-3 days for maintenance, while spiral heat exchangers may need up to a week.

Double Wall Plate Heat Exchangers

Double wall plate heat exchangers provide an extra layer of safety in environments where fluid mixing must be avoided. Each plate consists of two thin sheets, creating an external leakage pathway. This feature allows operators to detect leaks quickly and prevent cross-contamination.

Key Technical Advantages | Description |

|---|---|

External Leakage Pathway | Enables immediate visual detection of any failure, facilitating proactive maintenance. |

Absolute Fluid Separation | Prevents mixing of incompatible or hazardous media, ensuring process integrity. |

High Thermal Efficiency | Delivers the same heat transfer performance as conventional single-plate designs. |

Sanitary and Industrial Variants | Available in welded and non-welded configurations to meet both hygienic and industrial standards. |

Factories in the food, pharmaceutical, and chemical industries often use double wall plate heat exchangers to ensure safety and compliance with strict regulations.

Modular and Customizable Solutions

Modern factories require flexibility to adapt to changing production needs. Modular gasketed heat exchanger solutions allow operators to replace individual components, reducing long-term costs and downtime. Customization options include adjusting design parameters such as tube pitch, shell diameter, and flow arrangement. These features help optimize thermal performance for specific processes.

Benefit | Description |

|---|---|

Easy Maintenance | Modular designs allow for individual component replacement, reducing long-term costs. |

Lower Lifecycle Costs | Plate heat exchangers generally offer lower maintenance and lifecycle costs than traditional designs. |

Customization Aspect | Details |

|---|---|

Design Parameters | Tube pitch, shell diameter, and tube configuration can be tailored to specific needs. |

Flow Arrangement | Options include counterflow, parallel, or crossflow to optimize thermal performance. |

Industry | Application |

|---|---|

Power Generation | Used in energy production processes. |

Chemical Processing | Adaptable for various chemical reactions and processes. |

Food Processing | Customizable for specific temperature and fluid requirements in food production. |

Modular plate heat exchanger designs also support energy savings through real-time monitoring and early detection of inefficiencies. These benefits extend the system lifespan and reduce operating costs across sectors such as manufacturing and healthcare.

Shanghai Heat Transfer’s Gasketed Plate Heat Exchanger

Shanghai Heat Transfer’s gasketed plate heat exchanger stands out as a leading solution for modern factories. This product features a compact and modular design, achieving a surface-area density of 100–200 m²/m³. Factories benefit from a reduced physical footprint and enhanced energy recovery. The plate heat exchanger uses high-quality materials like stainless steel, titanium, and Hastelloy, ensuring durability in demanding environments.

The design allows two fluids to flow in a countercurrent pattern, maximizing heat transfer with U-values between 3,000 and 7,000 W/m²·K. Gaskets made from nitrile, EPDM, or Viton make maintenance simple and support Clean-in-Place (CIP) operations. The low fouling design further reduces downtime. Multi-pass configurations enable the gasketed heat exchanger to handle variable flow rates and temperature gradients, making it suitable for industries such as oil and gas, food and beverage, and environmental protection.

Shanghai Heat Transfer’s commitment to innovation and quality ensures that their gasketed plate heat exchangers deliver superior performance, energy efficiency, and reliability for a wide range of industrial applications.

Gasketed Plate Heat Exchangers Explained

Structure and Operation

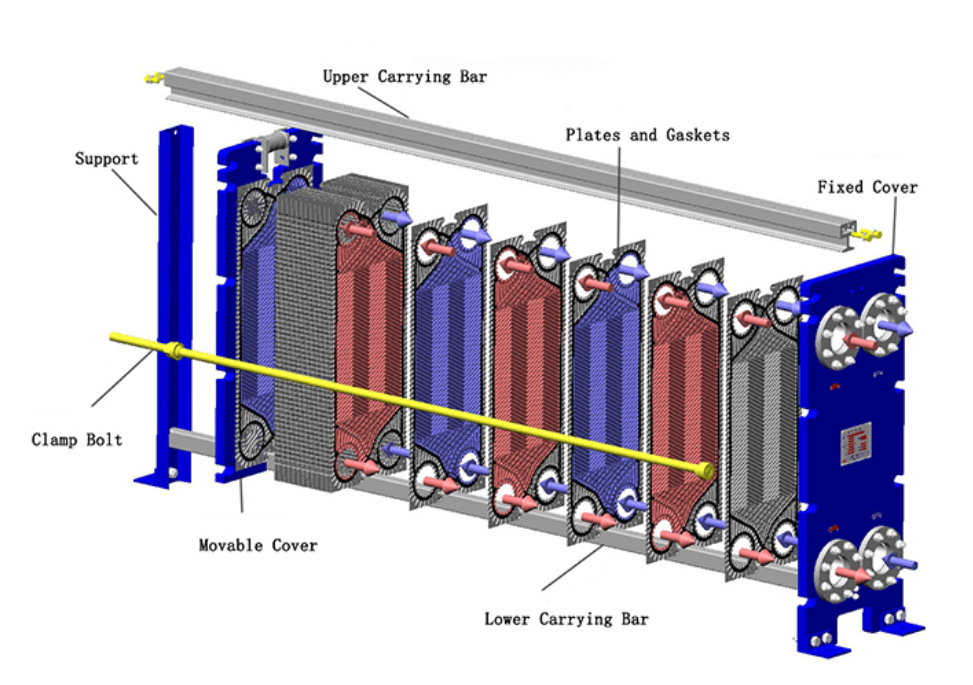

Gasketed plate heat exchangers use a series of parallel plates to create separate channels for fluid flow. Each plate sits next to another, forming alternating paths for hot and cold fluids. The plates often feature corrugated surfaces, which increase turbulence and improve thermal exchange. Operators can arrange the gaskets to allow vertical or diagonal flow, depending on process needs. This design helps factories achieve high heat transfer rates and flexible operation.

Plates form channels for fluids to flow in alternating directions.

Corrugated surfaces boost turbulence and heat transfer.

Gasket arrangements control flow direction, either vertical or diagonal.

The modular structure allows easy expansion or maintenance.

Key Materials and Gasket Types

Factories select materials and gasket types based on the fluids and operating conditions. The choice affects durability, chemical resistance, and temperature tolerance. Common gasket types include diagonal flow gaskets, parallel flow gaskets for channel plates, and end plate gaskets. The table below shows popular materials and their properties:

Material | Description |

|---|---|

Nitrile rubber (NBR) | Excellent resistance to oils, fuels, and chemicals; suitable for many uses. |

EPDM | Good resistance to heat, weathering, and ozone; ideal for outdoor settings. |

FKM | High temperature resistance and chemical compatibility; handles aggressive fluids. |

Rubber | Strong temperature resistance and flexibility; works well in high-heat areas. |

Operators match gasket types and materials to the specific requirements of each application. This approach ensures reliable sealing and long service life.

Comparison with Other Heat Exchanger Types

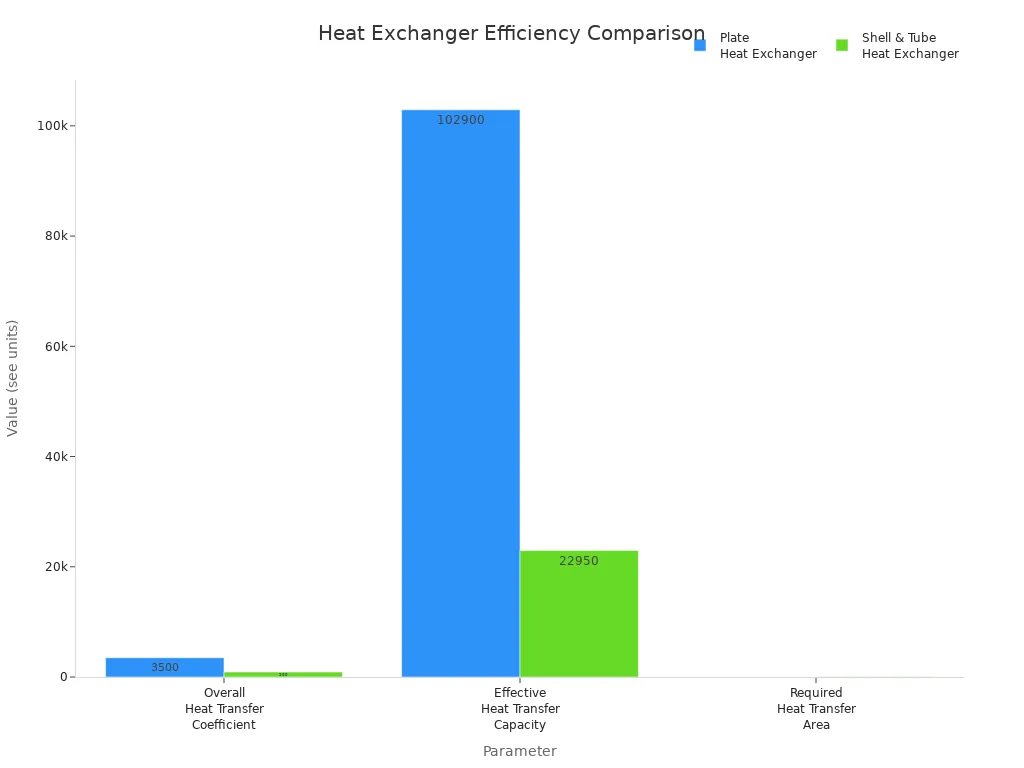

Gasketed plate heat exchangers outperform traditional shell and tube designs in several ways. They deliver higher heat transfer coefficients and require less surface area for the same capacity. Maintenance is easier because operators can access and clean individual plates without dismantling the entire unit. The table below highlights key differences:

Parameter | Plate Heat Exchanger | Shell & Tube Heat Exchanger |

|---|---|---|

Overall Heat Transfer Coefficient (U) | 3500 W/㎡·K | 900 W/㎡·K |

Effective Heat Transfer Capacity | ≈ 102,900 W/㎡ | ≈ 22,950 W/㎡ |

Required Heat Transfer Area (A) | ≈ 9.7 ㎡ | ≈ 43.6 ㎡ |

Factories choose gasketed plate heat exchangers for their superior efficiency, compact size, and simple maintenance. These advantages make them a preferred solution in modern industrial environments.

High Efficiency and Key Benefits

Superior Thermal Performance

Gasketed plate heat exchangers deliver outstanding performance in modern factories. Their design allows for rapid heat transfer between fluids, which reduces thermal resistance and boosts overall efficiency. Operators notice that these systems lower energy consumption and cut operational costs. The compact structure also helps maximize heat exchange capabilities.

They efficiently transfer heat between refrigerants and secondary fluids.

The design reduces thermal resistance, improving performance.

Lower energy use leads to cost savings and better efficiency.

Compact and Space-Saving Design

Factories often face space limitations. Gasketed plate heat exchangers solve this challenge with their compact footprint. These units can match the thermal duty of shell and tube exchangers while using up to 80% less space. The modular design lets operators add or remove plates as needed, making it easy to scale up or down.

The high-density heat transfer surface provides strong performance in a lightweight package.

Modular construction supports easy transportation and installation.

Space-saving design benefits factories with limited room.

These systems help factories achieve high efficiency, reliable performance, and easy maintenance, supporting productivity and sustainability goals.

Choosing the Right Gasketed Heat Exchanger

Assessing Process Needs

Factories must evaluate several process parameters before selecting a gasketed plate heat exchanger. These parameters help ensure the unit matches the application’s requirements.

Parameter | Importance |

|---|---|

Design Pressure | Determines the unit’s ability to handle internal stress. |

Physical Dimensions | Important for installation and space planning. |

Connection Sizes | Ensures compatibility with existing piping systems. |

Design pressure plays a key role in safety, as it sets the maximum pressure the heat exchanger can handle. In chemical processing, materials like titanium, Hastelloy, or stainless steel provide resistance to fouling and corrosion.

Energy Efficiency and Cost Savings

Factories can maximize energy efficiency and reduce costs by following several strategies:

Strategy | Description |

|---|---|

Pressure Drop Management | Selecting the right equipment and maintaining it saves energy over time. |

Flow Optimization | Proper flow rates improve heat transfer and lower energy use. |

Regular Maintenance | Clean systems operate more efficiently and last longer. |

Operators report up to 30% energy savings compared to traditional shell-and-tube systems, which also improves product quality.

Durability and Material Selection

Material choice impacts both durability and lifespan. Metal plates often last for decades, while gaskets may need replacement every three to ten years. Selecting the right gasket material prevents leaks and extends service life. NBR, EPDM, and Viton gaskets suit different temperatures and fluids. Proper material selection reduces downtime and keeps the system running smoothly.

Maintenance and Downtime

Regular maintenance helps minimize downtime. Key practices include:

Inspecting for wear, corrosion, or fouling.

Cleaning with Clean-In-Place (CIP) methods.

Replacing worn gaskets with compatible options.

Monitoring flow rates and thermal performance.

Scheduling professional inspections ensures the heat exchanger stays in top condition.

Customization Options

Factories often need custom solutions to fit unique requirements. Customization features include:

Customization Feature | Description |

|---|---|

Tailored Solutions | Designed for compatibility with various brands. |

Plate Design and Configuration | Adjusted for specific operating conditions. |

Performance Upgrades | Enhance efficiency and effectiveness. |

Minimal Downtime | Quick installation reduces disruptions. |

Expert guidance helps factories select the best configuration for their needs.

Leading Manufacturers and Innovations

Shanghai Heat Transfer’s Solutions

Shanghai Heat Transfer stands at the forefront of heat transfer technology. The company’s gasketed plate heat exchanger uses a modular design that supports high efficiency and easy maintenance. Engineers select advanced materials like stainless steel, titanium, and Hastelloy to ensure durability in demanding environments. The design maximizes heat transfer by using corrugated plates and high-quality gaskets. This approach allows factories to achieve precise temperature control and energy savings. Shanghai Heat Transfer’s solutions work in many industries, including HVAC, chemical processing, and power generation. Their commitment to innovation helps factories meet strict sustainability and performance goals. The company’s products support clean-in-place operations, which reduces downtime and keeps production lines running smoothly. Shanghai Heat Transfer continues to lead the way in heat transfer solutions for modern factories.

Recent Technological Advances

The field of heat transfer continues to evolve with new innovations. Recent advances have improved both performance and reliability in gasketed plate heat exchangers. Key developments include:

Advanced plate designs that enhance heat transfer efficiency and reduce pressure drop.

New sealing and gasket technology that increases durability and prevents leakage under high temperatures and pressures.

Improved material selection and corrosion resistance using advanced alloys and coatings.

Modular and customizable designs that allow for flexible applications and easier maintenance.

Enhanced heat transfer mechanisms, such as surface texturing and optimized flow patterns, which improve thermal efficiency and reduce fouling.

These innovations help factories achieve better heat transfer, lower energy use, and longer equipment life. As technology advances, manufacturers continue to push the boundaries of what is possible in industrial heat transfer.

Selection Guide for Modern Factories

Evaluating Factory Requirements

Factories must start by understanding their unique needs. Each process has different temperature, pressure, and flow requirements. Operators should gather data on these factors before contacting suppliers.By working closely with suppliers, factories can identify the best heat exchanger size and configuration. Suppliers may suggest materials that match the fluids and temperatures in use. Some suppliers even provide simulation tools to predict performance. Factories should ask suppliers for references from similar industries. Suppliers with experience in the same sector can offer valuable advice.

Comparing Design Features

Factories should compare the features offered by different suppliers. Suppliers may offer various plate patterns, gasket materials, and frame designs. Some suppliers focus on energy efficiency, while others highlight easy maintenance. Suppliers often provide technical datasheets that list performance values. Factories can request samples or demonstrations from suppliers. Suppliers may also offer warranties or service packages. Comparing these options helps factories choose the right product.

Working with Trusted Suppliers

Choosing the right suppliers is critical for long-term success. Trusted suppliers support factories through installation, training, and after-sales service. Suppliers who respond quickly to questions build confidence. Factories should look for suppliers with local support teams. Suppliers who stock spare parts reduce downtime. Many suppliers offer maintenance contracts for ongoing support. Suppliers with ISO certifications show commitment to quality. Factories should check if suppliers have experience with similar projects. Suppliers who provide clear documentation make installation easier. Good suppliers help with troubleshooting and upgrades. Suppliers who value long-term relationships offer better service. Factories benefit from suppliers who understand their business goals. Suppliers who invest in customer training improve safety. Reliable suppliers help factories adapt to new regulations. Suppliers who offer flexible payment terms support cash flow. Factories should review feedback from other customers about suppliers. Suppliers who listen to feedback improve their products. Factories should choose suppliers who communicate clearly. Suppliers who provide regular updates keep projects on track. Factories should build partnerships with suppliers for future growth.

FAQ

What makes gasketed heat exchangers reliable for modern factories?

Gasketed heat exchangers offer reliable performance because they use advanced materials and modular designs. Operators can easily maintain these units. Factories trust them for consistent operation and reliable heat transfer in demanding environments.

How do gasketed plate heat exchangers support sustainability?

Gasketed plate heat exchangers help factories achieve sustainability goals. They improve energy efficiency and reduce waste. Many factories use them for waste heat recovery. These systems support sustainable industrial practices by lowering energy use and supporting reliable operations.

What industries benefit most from gasketed heat exchangers?

Industries such as food processing, power generation, and chemical manufacturing use gasketed heat exchangers. These units offer reliable performance, support sustainability, and often replace shell and tube heat exchanger systems for better efficiency.