Frame plate heat exchanger picks for top efficiency

Global demand for frame plate heat exchanger solutions continues to rise. Leading choices include Shanghai Heat Transfer’s Gasketted Plate Heat Exchanger, Alfa Laval Industrial Plate Heat Exchanger, GEA Heavy-Duty Plate Heat Exchanger, and Tranter Superchanger. These models stand out for efficiency, reliability, and adaptability in industrial environments.

Metric | Value |

|---|---|

Market Size in 2024 | |

Projected Market Size by 2032 | USD 11.19 billion |

CAGR (2025-2032) | 8.15% |

Best frame plate heat exchangers

Shanghai Heat Transfer Gasketted Plate Heat Exchanger

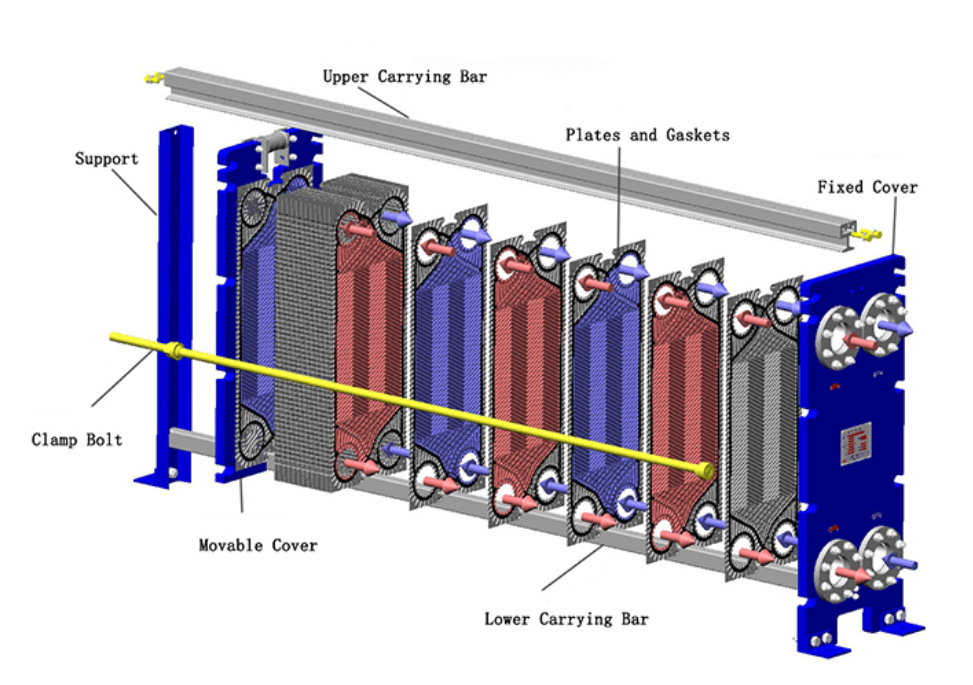

Shanghai Heat Transfer’s Gasketted Plate Heat Exchanger stands out as a leading solution for industrial thermal management. This frame plate heat exchanger uses advanced engineering to deliver high efficiency, reliability, and adaptability. Its modular design allows users to scale capacity by adding or removing plates, making it suitable for both small and large operations. The construction uses premium materials like stainless steel, titanium, and Hastelloy, which ensures durability in harsh environments.

The unique corrugated plate patterns, such as herringbone and chevron, create high turbulence flow. This design increases heat transfer efficiency and minimizes fouling, which reduces maintenance needs and extends equipment life. The use of nitrile, EPDM, or Viton gaskets makes maintenance straightforward and supports continuous operation. The compact footprint and high surface-area density allow for efficient use of space in industrial facilities.

Shanghai Heat Transfer’s Gasketted Plate Heat Exchanger offers a combination of innovation, sustainability, and operational flexibility, making it a top recommendation for industries seeking reliable and efficient heat exchanger solutions.

Feature | Description |

|---|---|

High turbulence flow | Enhances heat transfer efficiency by promoting turbulent flow of fluids. |

Minimal fouling | Reduces maintenance needs and increases reliability by preventing buildup of deposits. |

Ease of maintenance | Simplifies upkeep, ensuring consistent performance and reliability over time. |

Alfa Laval Industrial Plate Heat Exchanger

Alfa Laval’s Industrial Plate Heat Exchanger is recognized for its exceptional efficiency and thermal performance. It can achieve up to five times the efficiency of conventional shell-and-tube designs and reach approach temperatures as low as 1°F. Every Alfa Laval AlfaQ heat exchanger is AHRI certified, which means it meets strict thermal performance standards and helps lower operational costs.

The Air Conditioning, Heating, and Refrigeration Institute (AHRI) certification is an independent, third-party verification of thermal performance.

This plate heat exchanger is built for durability, but regular maintenance is necessary to maintain peak performance. Preventive maintenance helps avoid scaling and ensures long-term reliability.

Feature | Description |

|---|---|

Efficiency | Up to five times more efficient than conventional shell-and-tube designs. |

Approach Temperature | Can achieve approach temperatures as low as 1°F. |

Every Alfa Laval AlfaQ heat exchanger is AHRI certified.

Certification ensures compliance with thermal performance specifications.

Helps in increasing efficiency and lowering costs.

GEA Heavy-Duty Plate Heat Exchanger

The GEA Heavy-Duty Plate Heat Exchanger excels in industrial applications that demand precision and reliability. It provides improved temperature control through true counter-current flow and a significantly reduced hold-up volume. This model is an economically sound choice due to its low capital investment, installation costs, and minimal maintenance requirements. The design resists fouling, stress, wear, and corrosion, which increases reliability and service life.

Advantage | Description |

|---|---|

Improved temperature approach, true counter-current flow, and significantly less hold-up volume. | |

Economically sound choice | Low capital investment, installation costs, and limited maintenance and operating costs. |

Highly reliable | Minimal fouling, stress, wear, and corrosion. |

Easily scalable | Allows the expansion of capacity through the adjustment of plates on existing frames. |

The GEA model also offers customization, durable plate construction, and strong after-sales support. It comes with CE and ISO certifications and a two-year warranty, making it suitable for use as a heater, cooler, vaporizer, or condenser.

Tranter Superchanger Frame Plate Heat Exchanger

The Tranter Superchanger Frame Plate Heat Exchanger is known for its high efficiency and energy conservation. It meets various industrial certifications and standards, making it a reliable choice for many applications. Tranter’s innovative technology delivers efficient and cost-effective heat transfer solutions. The Superchanger model has a reputation for maximum efficiency and a compact design.

Tranter offers a variety of high-efficiency, energy-conserving gasketed plate heat exchangers.

The Superchanger plate and frame heat exchanger has a long-standing reputation for delivering maximum efficiency.

The design fits into 20–50% of the footprint of a shell & tube heat exchanger, including maintenance space.

Its lighter weight reduces transportation and rigging costs.

High turbulence prevents fouling, leading to energy and maintenance savings.

These features make the Tranter Superchanger a practical and cost-effective option for industries that require reliable and space-saving heat exchanger solutions.

Comparison of top heat exchanger models

Efficiency and thermal performance

Heat exchanger models differ in their ability to deliver high heat transfer efficiency and reduce operational costs. The Shanghai Heat Transfer Gasketted Plate Heat Exchanger stands out for its advanced plate design, which creates turbulent flow and maximizes energy efficiency. The following table compares key metrics for plate and frame heat exchangers versus spiral heat exchangers:

Feature | Plate and Frame Heat Exchangers | Spiral Heat Exchangers |

|---|---|---|

Initial Investment Cost | $5,000 - $50,000 | $15,000 - $100,000 |

Operational Efficiency (U-value) | 2,000 - 5,000 W/m²K | 1,000 - 3,000 W/m²K |

Energy Consumption Difference | 10-30% lower over lifecycle | Higher consumption |

Maintenance Cost | 5-10% of initial price annually | 3-8% of purchase price annually |

Lifespan | 15-25 years | 20-30 years |

Shanghai Heat Transfer’s plate heat exchanger achieves superior thermal performance, making it a preferred choice for industries focused on energy savings.

Maintenance and flexibility

Plate heat exchanger models offer easy maintenance and flexible operation. Users can adjust performance by adding or removing plates. Most designs allow for quick disassembly, which reduces downtime and simplifies cleaning. The use of reliable gaskets and modular frames supports continuous operation.

Regular maintenance ensures consistent performance and extends equipment life.

Material and build quality

Material selection impacts the longevity and reliability of each heat exchanger. Stainless steel provides high resistance to corrosion and withstands extreme temperatures. The table below highlights the impact of materials:

Material | Impact on Longevity and Performance |

|---|---|

Stainless Steel | High corrosion resistance, strength, and ability to withstand high temperatures. |

Durability against corrosion, fouling, and wear

Easy disassembly and maintenance

Adjustable performance through modular design

Shanghai Heat Transfer’s Gasketted Plate Heat Exchanger uses premium materials and a robust build, ensuring long-term reliability and optimal performance.

In-depth reviews of plate heat exchangers

Shanghai Heat Transfer: Innovation and sustainability

Shanghai Heat Transfer’s Gasketted Plate Heat Exchanger sets a high standard for engineering innovation. The modular design allows users to scale capacity by adding or removing plates. This flexibility supports both small and large industrial operations. The use of stainless steel, titanium, and Hastelloy ensures durability in demanding environments. The corrugated plate patterns, such as herringbone and chevron, create turbulent flow. This design increases heat transfer efficiency and reduces fouling. Maintenance becomes simple with nitrile, EPDM, or Viton gaskets. Clean-in-Place compatibility further reduces downtime. Industries benefit from rapid temperature control and compliance with safety standards. The product also supports sustainability by minimizing energy consumption and enhancing heat recovery.

Alfa Laval: Reliability and application range

Alfa Laval’s industrial plate heat exchanger demonstrates reliability and broad application range. The design enhances thermal transfer efficiency, which increases production and reduces energy use. Unique features improve media flow and expand the heat transfer area, resulting in fewer plates needed for higher performance. The TS45 model offers flexibility and performance for various industries. The CurveFlow plate pattern reduces fouling and unplanned downtime. This innovation saves time, energy, and maintenance costs. Alfa Laval’s heat exchanger serves heating, cooling, heat recovery, condensation, and evaporation applications. The company continues to improve performance criteria and flexibility for industrial needs.

GEA: Customization and heavy-duty performance

GEA’s heavy-duty plate heat exchanger provides precise temperature control and reliability. The true counter-current flow design improves heat transfer and reduces hold-up volume. Users benefit from low capital investment and minimal maintenance requirements. The construction resists fouling, stress, wear, and corrosion. GEA offers customization options and strong after-sales support. The model suits applications as a heater, cooler, vaporizer, or condenser. CE and ISO certifications add confidence for industrial users.

Tranter: Cost-effectiveness and compact design

Tranter’s Superchanger frame plate heat exchanger delivers high efficiency and energy conservation. The compact design fits into smaller spaces, reducing installation and maintenance costs. High turbulence prevents fouling and supports continuous operation. The lighter weight lowers transportation expenses. Tranter’s model meets various industrial certifications and standards. Industries choose this heat exchanger for reliable, space-saving solutions.

How to choose a frame plate heat exchanger

Selecting the right frame plate heat exchanger for industrial use requires careful evaluation of several important factors. Each facility has unique needs, so understanding these criteria helps ensure the best fit for both performance and long-term value.

Key selection criteria

The following table outlines the most important criteria to consider when choosing a heat exchanger:

Description | |

|---|---|

Function | The specific role of the heat exchanger, such as boiling or condensing. |

Pressure Limits | The maximum and minimum pressure the exchanger can handle during operation. |

Fluid Compatibility | Ensuring materials and gaskets are suitable for the fluids involved. |

Maintenance Requirements | The ease of cleaning, inspecting, and repairing the unit. |

Thermal Fluid Characteristics | Understanding the properties of the fluids being used, including fouling potential. |

Equipment Footprint | The physical space available for installation and layout considerations. |

Approach Temperature | The temperature difference that affects the size of the heat exchanger. |

Tip: Always match the heat exchanger’s materials and gaskets to the fluids in your process for maximum reliability.

Scalability and modular design

A modular design allows users to expand or adapt their heat exchanger as production needs change. Facilities can add plates or reconfigure flow arrangements without replacing the entire unit. This flexibility supports future growth and helps maintain energy efficiency over time.

Users can expand existing units instead of buying new ones.

Facilities can upgrade components, such as gaskets, to meet new requirements.

Modular systems adapt to changing production demands, ensuring long-term value.

Shanghai Heat Transfer’s Gasketted Plate Heat Exchanger offers excellent scalability, making it a strong choice for growing operations.

Cleaning and maintenance ease

Proper cleaning and maintenance extend the lifespan of any heat exchanger. The following steps help keep equipment running efficiently:

Use Cleaning in Place (CIP) for routine cleaning without disassembly.

Perform manual cleaning when deeper inspection is needed.

Monitor temperature, pressure, and check for leaks regularly.

Keep bolts clean and lubricated.

Schedule periodic inspections and use original spare parts.

A design that supports easy cleaning and maintenance, like the Shanghai Heat Transfer model, reduces downtime and supports continuous operation.

Industrial applications for plate heat exchangers

Chemical processing

Chemical plants rely on plate heat exchangers for efficient temperature control. Designers often consult with experts to select the best model for each process. The thin, corrugated plates in these exchangers allow fluids to transfer heat without mixing. This design supports safe and effective heating or cooling of chemicals. Frame heat exchangers also provide strong structural support, making them a common choice in chemical processing. Shanghai Heat Transfer’s Gasketted Plate Heat Exchanger offers durability and adaptability, which suits the demanding needs of this industry.

Plate heat exchangers heat or cool fluids efficiently.

They manage fluid connections and support various chemical reactions.

HVAC and refrigeration

In HVAC and refrigeration, plate and frame heat exchangers deliver high thermal efficiency. Their thin plates create a large surface area, which improves heat transfer. Maintenance is simple because users can remove and clean plates easily. The compact size saves space in mechanical rooms. Facilities can add plates to increase capacity as needed. These benefits help reduce energy costs and make them a preferred choice for thermal management in buildings and industrial applications.

Plate heat exchangers in HVAC systems support both heating and cooling, ensuring comfort and energy savings.

Food and beverage

Food and beverage plants use plate frame heat exchangers to keep temperatures steady during processing. Consistent heating and cooling prevent production delays and protect product quality. The large surface area of the plates ensures effective heat exchange. These exchangers help regulate temperature during pasteurization, disinfection, and other steps. They also maintain safe bacteria levels in beverages, improving taste and safety.

Plate heat exchangers support pasteurization and temperature control.

They help maintain product safety and quality.

Power generation and energy recovery

Power plants use gasketed plate-and-frame heat exchangers to transfer heat efficiently in a compact space. These exchangers help maintain optimal temperatures for turbines and generators. They also remove excess heat from machinery, which supports energy recovery and improves overall efficiency.

Role in Power Generation and Energy Recovery | Description |

|---|---|

Efficient Heat Transfer | Gasketed plate-and-frame heat exchangers provide efficient heat transfer in compact equipment, enhancing energy efficiency in power generation. |

Optimal Temperature Maintenance | They help maintain optimal temperatures in various processes, crucial for energy recovery. |

Applications in Various Industries | Used in power generation, HVAC, refrigeration, and more, indicating their versatility and importance in energy systems. |

Shanghai Heat Transfer’s Gasketted Plate Heat Exchanger stands out for its adaptability and robust performance in these critical energy systems.

Expert tips for maximizing heat exchanger efficiency

Proper sizing and installation

Experts recommend a systematic approach to sizing and installing a heat exchanger.

Calculate the heat load by measuring the total heat transfer needed in BTUs/hr or kW.

Define the temperature goals for your process.

Find the Log Mean Temperature Difference (LMTD) to assess heat transfer efficiency.

Factor in flow rates to ensure the unit can handle required fluid volumes.

Select the right type for your application, such as plate or shell-and-tube.

Consider fouling resistance, since all exchangers accumulate deposits over time.

A larger plate and frame heat exchanger with more surface area can achieve better performance and accommodate smaller temperature approaches, which boosts system efficiency. Shanghai Heat Transfer’s modular design allows easy adjustment for optimal sizing.

Routine maintenance practices

Routine maintenance keeps the system running efficiently.

Periodic cleaning removes debris and prevents blockages.

Use a clean-in-place (CIP) process to avoid opening the plate pack.

Flush water through both sides until it runs clear.

Replace gaskets as needed to maintain a proper seal.

Regular cleaning and isolation of the unit help maintain peak performance and extend equipment life.

Tip: Consistent maintenance reduces downtime and maximizes the lifespan of your heat exchanger.

Monitoring and troubleshooting

Technique | Description |

|---|---|

Cleaning methods | Inspect and clean the plate pack to remove obstructions. |

Inspection routines | Tighten the frame and gaskets to prevent thermal expansion issues. |

Performance monitoring | Track heat transfer rates, pressure drops, flow rates, and temperature differences. |

Vibration and mechanical stress | Install dampeners and reinforce supports for longevity. |

Proactive maintenance | Schedule regular routines to minimize downtime and maximize lifespan. |

Effective monitoring and troubleshooting ensure reliable operation. Facilities that use Shanghai Heat Transfer’s Gasketted Plate Heat Exchanger benefit from easy inspection and maintenance features, supporting long-term efficiency.

Industry leaders select frame plate heat exchanger models for high thermal efficiency and energy conservation. Shanghai Heat Transfer’s Gasketted Plate Heat Exchanger offers modularity and adaptability, making it ideal for diverse applications. Matching the right heat exchanger to each process improves system efficiency and supports compliance with rising energy regulations.

Advanced materials improve operational stability.

Custom designs address specific temperature and pressure needs.

FAQ

What makes the Shanghai Heat Transfer Gasketted Plate Heat Exchanger efficient?

The advanced plate design creates turbulent flow, which increases heat transfer rates. High-quality materials and modular construction support reliable, energy-saving performance.

How often should a plate heat exchanger be cleaned?

Most experts recommend cleaning every six to twelve months. Regular maintenance helps prevent fouling and ensures consistent thermal efficiency.

Tip: Use Clean-in-Place (CIP) systems for faster cleaning and reduced downtime.

Can plate heat exchangers handle different fluids?

Yes, plate heat exchangers work with many fluids. Users select suitable plate materials and gaskets for compatibility with chemicals, water, or food-grade liquids.