Gasketed Plate Heat Exchangers Transforming Industrial Efficiency

Compact Design and Space-Saving Benefits of Gasketed Plate Heat Exchangers

Gasketed plate heat exchangers improve energy efficiency in industrial settings. Their advanced design enables rapid heat transfer and cost savings. Operators benefit from flexible performance and reduced downtime.

Many industries choose these exchangers to support higher productivity and sustainability goals.

Minimal Footprint in Industrial Environments

Industrial facilities often face space limitations. Equipment that occupies less floor area allows operators to optimize layouts and improve workflow. Gasketed plate heat exchangers feature a slim profile and vertical stacking, which reduces the amount of space needed for installation. Many factories choose these exchangers because they fit into tight spaces where traditional equipment cannot.

Facilities that use compact heat exchangers can allocate more room for production lines, storage, or other critical operations. This advantage supports higher productivity and better resource management.

A comparison table highlights the difference in footprint between gasketed plate heat exchangers and conventional shell-and-tube models:

| Equipment Type | Typical Footprint (sq. ft.) | Space Efficiency |

|---|---|---|

| Gasketed Plate Heat Exchanger | 5–15 | High |

| Shell-and-Tube Heat Exchanger | 20–40 | Moderate |

Simplified Installation and Integration Processes

Gasketed plate heat exchangers offer straightforward installation. Their modular design allows technicians to assemble units quickly and connect them to existing systems with minimal disruption. Many models arrive pre-assembled, which shortens setup time.

Operators benefit from easy integration with pumps, valves, and control systems. The lightweight construction makes transportation and positioning easier. Maintenance teams appreciate the reduced need for heavy lifting equipment during installation.

A simple installation process leads to lower labor costs and faster commissioning. Facilities can begin operations sooner and avoid delays that impact production schedules.

Superior Heat Transfer Efficiency and Energy Savings with Gasketed Plate Heat Exchangers

Enhanced Plate Surface Area for Rapid Heat Exchange

Engineers design gasketed plate heat exchangers with a large surface area. Each plate features a pattern that creates turbulence as fluids pass through. This turbulence increases the contact between the fluids and the plate surfaces. As a result, heat transfers quickly from one fluid to another.

Operators notice that these exchangers reach target temperatures faster than traditional models. The thin plates and narrow channels allow for efficient heat movement. Many industries rely on this rapid exchange to maintain consistent product quality and process speed.

A comparison of heat transfer rates:

| Exchanger Type | Typical Heat Transfer Rate (BTU/hr·ft²) |

|---|---|

| Gasketed Plate Heat Exchanger | 2,500 – 5,000 |

| Shell-and-Tube Heat Exchanger | 1,000 – 2,500 |

Reduced Energy Consumption and Operational Costs

Gasketed plate heat exchangers help facilities lower energy use. The efficient design means less energy is needed to achieve the same temperature change. Operators see a direct reduction in utility bills.

Lower energy consumption also means less strain on equipment. Pumps and other components work under lighter loads. This leads to fewer breakdowns and longer equipment life. Over time, companies save money on both energy and maintenance.

Many organizations choose these exchangers to meet energy-saving goals. They support both cost control and environmental responsibility.

Flexible, Modular Configurations of Gasketed Plate Heat Exchangers

Easy Expansion and Customization Options

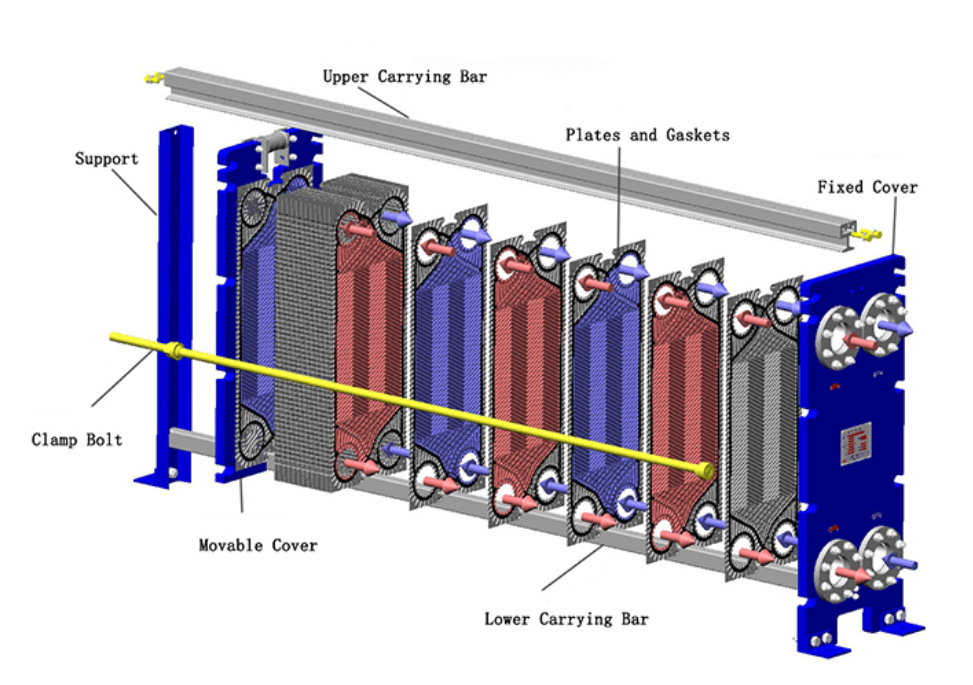

Engineers often select gasketed plate heat exchangers for their modular design. Each unit consists of individual plates held together by a sturdy frame. Operators can add or remove plates to adjust the capacity. This process does not require specialized tools or lengthy downtime. Facilities benefit from the ability to scale up operations as demand increases.

Customization remains straightforward. Manufacturers offer plates in different materials and patterns. Operators choose the best configuration for their process fluids and temperature requirements. The modular approach supports a wide range of industrial applications.

A table below highlights common customization features:

| Feature | Benefit |

|---|---|

| Plate Material | Handles corrosive fluids |

| Plate Pattern | Optimizes heat transfer |

| Frame Size | Matches process scale |

Adaptability to Evolving Process Requirements

Industrial processes change over time. Gasketed plate heat exchangers adapt quickly to new conditions. Operators modify the plate arrangement or swap out gaskets to handle different fluids. This flexibility supports process upgrades and product changes.

Facilities avoid costly equipment replacements. The modular system allows for quick adjustments without major investments. Teams maintain high efficiency even as production needs shift. Adaptability ensures long-term value and reliable performance.

A checklist for adaptability:

·Adjust plate count for higher or lower capacity

·Change plate material for new fluids

·Replace gaskets to improve sealing

Ease of Maintenance and Reliability of Gasketed Plate Heat Exchangers

Quick Access for Cleaning and Inspection

Operators value equipment that allows fast and easy cleaning. Gasketed plate heat exchangers feature a design that enables quick access to internal plates. Technicians can open the frame and remove individual plates without special tools. This process helps teams inspect surfaces for fouling or wear. Regular cleaning keeps heat transfer rates high and prevents contamination in sensitive processes.

Many facilities schedule routine inspections to maintain reliability. The simple disassembly process reduces the time needed for each inspection. Teams can identify issues early and take corrective action before problems escalate. The straightforward access supports strict hygiene standards in industries such as food processing and pharmaceuticals.

Benefits of quick access:

·Faster cleaning cycles

·Easier visual inspection

·Reduced risk of contamination

Minimized Downtime and Maintenance Expenses

Downtime impacts productivity and profit. Gasketed plate heat exchangers minimize interruptions by allowing rapid maintenance. Technicians replace worn gaskets or damaged plates in a short time. The modular design means only affected components need attention, not the entire unit.

Facilities save money on labor and spare parts. Maintenance teams spend less time on repairs, which keeps production lines running smoothly. The reliability of these exchangers leads to fewer emergency shutdowns and lower overall maintenance costs.

| Maintenance Task | Time Required | Cost Impact |

|---|---|---|

| Plate Cleaning | Short | Low |

| Gasket Replacement | Short | Low |

| Full Unit Overhaul | Rare | Moderate |

Cost-Effectiveness and Long-Term Savings from Gasketed Plate Heat Exchangers

Lower Initial Investment Compared to Traditional Alternatives

Many industrial managers seek equipment that delivers strong performance without high upfront costs. Gasketed plate heat exchangers offer a lower initial investment than shell-and-tube models. Manufacturers design these units with fewer raw materials and simpler assembly processes. Facilities often purchase smaller units that meet their needs and expand later if required. This approach helps companies control capital spending and allocate budgets more efficiently.

A comparison table demonstrates the difference in initial investment:

| Exchanger Type | Average Initial Cost (USD) | Installation Complexity |

|---|---|---|

| Gasketed Plate Heat Exchanger | $5,000 – $15,000 | Low |

| Shell-and-Tube Heat Exchanger | $10,000 – $30,000 | Moderate |

Extended Equipment Lifespan and Improved ROI

Gasketed plate heat exchangers deliver long-term value through durable construction and easy maintenance. Operators replace individual plates or gaskets when needed, which extends the life of the entire unit. Regular cleaning and inspection prevent major failures and keep performance high. Many facilities report fewer breakdowns and lower repair costs over time.

A longer lifespan leads to a stronger return on investment (ROI). Companies spend less on replacements and avoid costly downtime. The modular design supports upgrades, so equipment stays relevant as processes change. Industrial leaders recognize that investing in reliable heat exchangers improves financial outcomes year after year.

Key benefits of extended lifespan:

·Fewer replacements

·Lower maintenance costs

·Consistent performance

Gasketed Plate Heat Exchangers vs. Traditional Shell-and-Tube Exchangers

Performance Differences and Efficiency Improvements

Engineers often compare gasketed plate heat exchangers with shell-and-tube models to evaluate performance. Gasketed plate heat exchangers deliver higher thermal efficiency because their plates create turbulent flow. This turbulence increases the rate of heat transfer between fluids. Shell-and-tube exchangers rely on larger volumes and less surface area, which limits their efficiency.

Operators observe faster temperature changes with plate designs. The thin plates and narrow channels allow fluids to move quickly and exchange heat more effectively. Shell-and-tube units require more time to reach target temperatures. This difference impacts process speed and product quality.

A table below highlights key performance metrics:

| Feature | Gasketed Plate Heat Exchanger | Shell-and-Tube Exchanger |

|---|---|---|

| Heat Transfer Rate | High | Moderate |

| Response Time | Fast | Slow |

| Energy Consumption | Low | Higher |

| Space Requirement | Small | Large |

Practical Considerations for Industrial Use

Industrial managers evaluate several factors before choosing a heat exchanger. Gasketed plate heat exchangers offer easier installation and maintenance. Technicians can access plates for cleaning or replacement without special tools. Shell-and-tube models often require more labor and downtime for service.

Operators value the modular design of plate exchangers. They can add or remove plates to adjust capacity. Shell-and-tube units do not provide this flexibility. Expansion or modification usually means replacing the entire unit.

A checklist for practical selection:

·Assess available space in the facility

·Review maintenance requirements

·Consider future expansion needs

·Compare initial and long-term costs

Engineers recommend plate exchangers for processes that demand frequent cleaning or rapid changes in capacity. Shell-and-tube models suit applications with stable requirements and less need for flexibility.

Environmental Advantages and Sustainability of Gasketed Plate Heat Exchangers

Reduced Carbon Footprint and Resource Consumption

Industrial leaders recognize the importance of reducing environmental impact. Gasketed plate heat exchangers help facilities lower their carbon footprint. These units transfer heat efficiently, which means less energy is required for daily operations. Lower energy use leads to fewer greenhouse gas emissions. Many factories report significant drops in electricity and fuel consumption after switching to these exchangers.

Operators also notice a decrease in water and raw material usage. The compact design and high efficiency allow processes to run with minimal waste. Facilities that use these exchangers often meet strict environmental regulations with ease.

Companies that prioritize sustainability choose equipment that supports resource conservation and cleaner production.

A table below shows typical resource savings:

| Resource Type | Savings (%) |

|---|---|

| Energy | 20–40 |

| Water | 15–30 |

| Raw Materials | 10–25 |

Support for Green Manufacturing Initiatives

Manufacturers strive to meet green standards and certifications. Gasketed plate heat exchangers align with these goals by promoting energy efficiency and reducing waste. Many organizations use these exchangers to support ISO 14001 and other environmental management systems.

Facilities can integrate these units into recycling and heat recovery systems. This approach helps companies reuse energy and minimize landfill waste. Operators find it easier to report positive environmental metrics when using advanced heat exchangers.

·Supports compliance with global sustainability standards

·Enables participation in eco-friendly programs

·Improves public image and stakeholder trust

Food and Beverage Processing

Food and beverage plants rely on precise temperature control to ensure product safety and quality. Gasketed plate heat exchangers help operators pasteurize milk, cool juices, and heat sauces quickly. These units handle frequent cleaning cycles, which supports hygiene standards. Many facilities choose them for their ability to process different products without cross-contamination. Operators benefit from rapid changeovers and consistent results.

Common uses in food and beverage:

·Pasteurization of dairy products

·Cooling of beverages

·Heating of syrups and sauces

Chemical and Petrochemical Manufacturing

Chemical plants require equipment that withstands aggressive fluids and high temperatures. Gasketed plate heat exchangers offer corrosion-resistant plates and flexible configurations. Engineers select them for tasks such as heating reactants, cooling solvents, and recovering energy from process streams. These exchangers adapt to changing production volumes and support safe operation.

| Application | Benefit |

|---|---|

| Heating reactants | Fast temperature rise |

| Cooling solvents | Reliable performance |

| Energy recovery | Lower utility costs |

HVAC and Power Generation Sectors

Heating, ventilation, and air conditioning systems use gasketed plate heat exchangers to transfer heat between water loops. Power plants install these units to improve boiler efficiency and recover waste heat. Operators value their compact size and easy maintenance. These exchangers help facilities reduce energy consumption and maintain stable temperatures.

Key roles in HVAC and power generation:

·District heating and cooling

·Boiler feedwater preheating

·Waste heat recovery

·Gasketed plate heat exchangers drive new standards in industrial efficiency.

·Their advanced design supports cost savings and reliable operation.

·Companies see measurable gains in productivity, energy use, and sustainability.

·These exchangers remain essential for modern facilities seeking long-term performance improvements.

FAQ

What industries benefit most from gasketed plate heat exchangers?

Food processing, chemical manufacturing, HVAC, and power generation sectors gain the most value. These industries require efficient heat transfer, easy maintenance, and flexible configurations.

How often should operators perform maintenance on gasketed plate heat exchangers?

Operators should inspect and clean the units every three to six months. Frequency depends on process fluids, operating conditions, and industry standards.

Can gasketed plate heat exchangers handle corrosive fluids?

Yes. Manufacturers offer plates in stainless steel, titanium, and other alloys. These materials resist corrosion and support safe operation with aggressive chemicals.