How do gaskets prevent leaks in heat exchangers

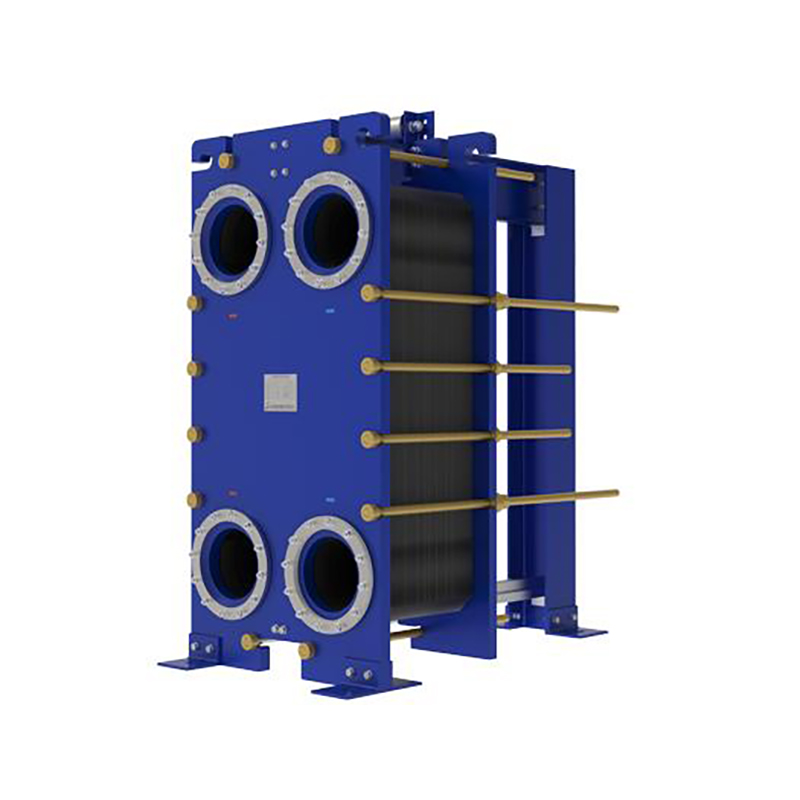

How a Gasket in Heat Exchanger Creates a Leak-Proof Seal

Sealing Mechanism

A gasket in heat exchanger forms a tight seal by compressing between two surfaces. The pressure applied during installation causes the gasket material to fill microscopic gaps and irregularities. This process blocks fluid pathways and prevents leaks. Engineers select gasket designs that match the flange shape and surface finish. The right compression ensures the seal remains intact under operating conditions.

Separation of Fluids

Heat exchangers often handle fluids with different properties. The gasket in heat exchanger acts as a barrier, keeping these fluids apart. This separation is critical in systems where mixing could cause damage or reduce efficiency. Operators rely on the gasket to maintain distinct flow channels. The design of the gasket matches the layout of the heat exchanger plates or tubes.

Key benefits of fluid separation:

·Protects equipment from corrosion

·Maintains process purity

·Supports efficient heat transfer

Preventing Cross-Contamination

Cross-contamination can lead to costly downtime and safety risks. The gasket in heat exchanger prevents unwanted mixing by sealing off each fluid stream. In food processing or chemical plants, this function is especially important. The gasket material resists chemical attack and withstands temperature changes. Operators choose gaskets that meet industry standards for hygiene and safety.

| Risk of Cross-Contamination | Gasket Solution |

|---|---|

| Product spoilage | Chemical-resistant gasket |

| Equipment damage | High-temperature gasket |

| Safety hazards | Certified food-grade gasket |

Gasket Materials and Performance in Heat Exchangers

Material Selection for Pressure and Temperature

Engineers select gasket materials based on the pressure and temperature demands of the system. A gasket in heat exchanger must withstand high pressures without deforming or losing its seal. For example, graphite and metal gaskets perform well in extreme temperatures. Rubber and elastomeric gaskets suit lower temperature applications. The right material ensures the gasket maintains its shape and sealing ability during operation.

Resistance to Corrosion and Chemicals

Heat exchangers often handle aggressive fluids. The gasket in heat exchanger must resist corrosion and chemical attack. Materials like PTFE (polytetrafluoroethylene) and certain metals offer excellent chemical resistance. These gaskets prevent leaks even when exposed to acids, bases, or solvents. Operators choose materials that match the chemical properties of the fluids in the system.

| Gasket Material | Chemical Resistance | Common Use Case |

|---|---|---|

| PTFE | Excellent | Chemical processing |

| Graphite | Good | High-temperature |

| Rubber | Moderate | Water, mild fluids |

Durability and Longevity

A reliable gasket in heat exchanger provides long service life. Durable materials reduce the need for frequent maintenance or replacement. Metal and composite gaskets often last longer in harsh environments. Proper installation and regular inspection also extend gasket life. Operators monitor for signs of wear, such as hardening or cracking, to ensure continued leak prevention.

·Gaskets play a vital role in heat exchangers.

·The correct gasket provides a strong seal under tough conditions.

·Technicians inspect and install gaskets properly to keep systems safe.

Regular maintenance helps operators prevent leaks and maintain efficient heat transfer.

FAQ

What causes gasket failure in heat exchangers?

Gasket failure often results from improper installation, excessive pressure, or chemical attack. Operators should monitor for leaks and replace damaged gaskets promptly.

How often should technicians inspect gaskets in heat exchangers?

Technicians should inspect gaskets during routine maintenance or whenever system performance drops. Early detection of wear helps prevent leaks and costly downtime.

Can operators reuse gaskets after disassembly?

Most gaskets lose their sealing ability after removal. Operators should always install a new gasket to ensure a reliable, leak-proof seal.