How to Maximize Energy Efficiency Using Refrigeration Heat Exchangers

Understanding Refrigeration Heat Exchangers

What Is a Refrigeration Heat Exchanger?

A refrigeration heat exchanger transfers thermal energy between two fluids in a refrigeration system. This device helps move heat from one area to another, supporting cooling or heating processes. Engineers design these exchangers to maximize contact between fluids while keeping them separate. The most common applications include air conditioning units, industrial chillers, and commercial refrigeration systems.

Key features of a refrigeration heat exchanger:

·Efficient thermal transfer

·Compact design for space savings

·Durable materials for long-term use

Operators select the right model based on system requirements, fluid types, and desired efficiency. The correct choice ensures optimal performance and reliability.

Why Refrigeration Heat Exchangers Matter for Energy Efficiency

A refrigeration heat exchanger plays a vital role in reducing energy consumption. By recovering and reusing heat, the system lowers the demand for additional energy input. This process leads to lower utility costs and improved sustainability.

The table below highlights the main benefits:

| Benefit | Impact on Energy Efficiency |

|---|---|

| Heat recovery | Reduces wasted energy |

| Improved system balance | Lowers operational costs |

| Enhanced reliability | Minimizes downtime |

Facility managers who prioritize efficient heat exchanger operation achieve measurable improvements in energy use.

Types of Refrigeration Heat Exchangers and Their Efficiency Benefits

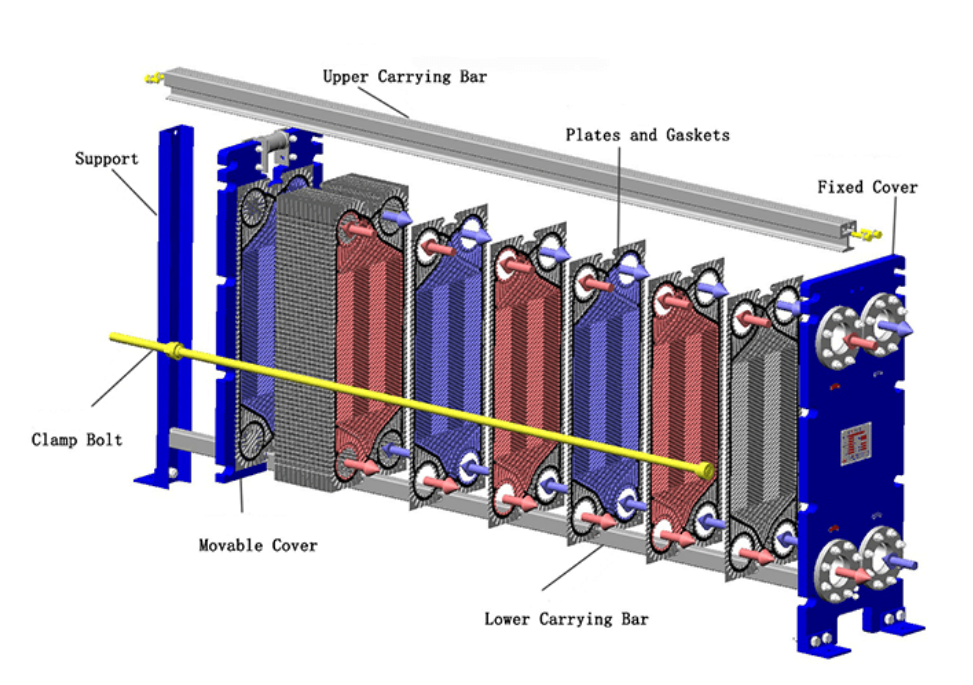

Plate Refrigeration Heat Exchangers

Plate refrigeration heat exchangers use a series of thin, corrugated metal plates to transfer heat between fluids. These plates create large surface areas, which improve thermal efficiency. Operators often choose this type for compact systems and applications that require quick temperature changes. Maintenance is straightforward because the plates can be removed and cleaned easily.

Key benefits:

·High heat transfer rates

·Small footprint

·Easy cleaning and maintenance

Shell-and-Tube Refrigeration Heat Exchangers

Shell-and-tube refrigeration heat exchangers consist of a bundle of tubes inside a cylindrical shell. One fluid flows through the tubes, while another passes around them within the shell. This design handles high pressures and temperatures well. Many industrial facilities rely on this type for its durability and flexibility.

Microchannel Refrigeration Heat Exchangers

Microchannel refrigeration heat exchangers feature multiple small channels that allow fluids to flow with minimal resistance. The design increases surface area and reduces refrigerant charge. These exchangers work well in modern HVAC systems, where energy efficiency and compact size matter most.

Comparing Efficiency Across Refrigeration Heat Exchanger Types

| Type | Efficiency | Maintenance | Size |

|---|---|---|---|

| Plate | High | Easy | Compact |

| Shell-and-Tube | Moderate | Moderate | Large |

| Microchannel | Very High | Moderate | Very Small |

Each refrigeration heat exchanger type offers unique efficiency benefits. Facility managers should match the type to their system’s needs for the best results.

Strategies to Maximize Energy Efficiency with Refrigeration Heat Exchangers

Proper Selection and Sizing of Refrigeration Heat Exchangers

Selecting the right refrigeration heat exchanger starts with understanding the system’s cooling or heating load. Engineers analyze the required capacity, temperature range, and fluid properties. They choose a model that matches the system’s needs without oversizing or undersizing. Oversized units waste energy and increase costs. Undersized units struggle to maintain performance and may fail prematurely.

A well-sized heat exchanger ensures efficient thermal transfer. Facility managers review manufacturer specifications and consult with experts. They consider factors such as flow rates, pressure drops, and compatibility with refrigerants. Proper selection leads to lower energy consumption and longer equipment .

Best Practices for Installation and Operation

Correct installation plays a major role in maximizing efficiency. Technicians follow manufacturer guidelines and industry standards. They ensure secure connections, proper insulation, and correct orientation. Poor installation can cause leaks, pressure drops, or reduced heat transfer.

Operators monitor system parameters during startup. They check for unusual noises, vibrations, or temperature fluctuations. Routine checks help identify issues early. Staff receive training on optimal operation, including adjusting flow rates and maintaining recommended temperature differentials.

Checklist for Efficient Operation:

·Inspect all connections for leaks

·Confirm insulation coverage

·Monitor inlet and outlet temperatures

·Adjust flow rates as needed

Maintenance and Monitoring for Sustained Performance

Regular maintenance keeps the refrigeration heat exchanger operating at peak efficiency. Technicians clean surfaces to remove scale, debris, or biological growth. They inspect for corrosion, cracks, or worn gaskets. Scheduled maintenance reduces the risk of unexpected breakdowns.

Facilities use monitoring systems to track performance metrics. Sensors measure temperature, pressure, and flow rates. Data analysis helps identify trends and predict maintenance needs. Early detection of problems prevents energy waste and extends equipment life.

Innovations and Upgrades in Refrigeration Heat Exchanger Technology

Recent advances in heat exchanger technology offer new ways to boost energy efficiency. Manufacturers develop models with improved materials, such as enhanced aluminum alloys or advanced coatings. These materials resist corrosion and improve heat transfer.

Microchannel designs and compact plate exchangers reduce refrigerant charge and footprint. Smart controls optimize operation based on real-time data. Facilities that upgrade to modern equipment often see immediate energy savings and lower maintenance costs.

A comparison of traditional and modern features:

| Feature | Traditional Models | Modern Upgrades |

|---|---|---|

| Material | Standard metals | Enhanced alloys |

| Design | Basic geometry | Microchannel/plate |

| Controls | Manual | Smart/digital |

| Maintenance | Reactive | Predictive/automated |

Facilities that invest in innovative solutions position themselves for long-term efficiency and reliability.

·Proper selection, sizing, and installation of refrigeration heat exchangers drive energy efficiency.

·Regular maintenance and monitoring support long-term performance.

·New technologies and upgrades reduce costs and improve reliability.

Consistent attention to best practices ensures lasting energy savings and optimal system operation.

FAQ

How often should technicians clean refrigeration heat exchangers?

Technicians should clean heat exchangers every six months. Regular cleaning prevents scale buildup and maintains optimal energy efficiency.

What signs indicate a refrigeration heat exchanger needs maintenance?

·Reduced cooling performance

·Unusual noises

·Higher energy bills

Facility managers should schedule inspections when these signs appear.

Can upgrading to a modern heat exchanger reduce energy costs?

| Upgrade Type | Expected Savings |

|---|---|

| Microchannel | Up to 30% |

| Enhanced Plate | Up to 25% |

Modern models deliver significant energy savings and lower maintenance expenses.