How to Select the Right Compact Heat Exchanger for Your Needs in 2025

Define Process and Thermal Requirements

Engineers must first clarify the process and thermal requirements before they select a heat exchanger. Key parameters include heat transfer rate, overall heat transfer coefficient, log mean temperature difference, number of transfer units, flow configuration, heat transfer surface area, pressure drop, effectiveness, fouling factor, material selection, capacity ratio, and safety factors. The relationship between temperature and pressure requirements plays a critical role in heat exchanger sizing. Higher pressures can raise boiling points, which improves heat transfer efficiency and reduces operational costs. The approach temperature, or the difference between hot and cold streams, also impacts thermal efficiency and sizing.

Heat transfer rate (Q)

Flow rate

Cooling medium availability

Heat exchanger sizing

Analyze Fluids and Material Compatibility

The type of fluids and their properties affect material compatibility and performance. For example, stainless steel resists scaling and oxidation, making it suitable for hygienic applications. Titanium offers high corrosion resistance in harsh environments. The table below shows common materials and their properties:

Material Type | Key Properties |

|---|---|

Copper Alloys | Excellent for seawater resistance |

Stainless Steel | Resists scaling and oxidation, good for hygiene |

Titanium | High corrosion resistance in harsh environments |

Consider Space and Heat Exchanger Sizes

Industrial settings often have strict space constraints. Compact heat exchangers feature compact designs that minimize installation costs and mechanical stresses. Plate heat exchangers can be only one-third to one-fifth the size and weight of traditional models. This space efficiency allows for easier maintenance and replacement. Heat exchanger sizes must match both process needs and available space.

Plan for Maintenance and Compliance

Maintenance and compliance requirements ensure long-term reliability. Openable bolted connections, like those on Shanghai Heat Transfer’s TP Welded Plate Heat Exchanger, allow for easy cleaning and inspection. Compliance with standards such as ASME Section VIII, TEMA, and FDA is essential for safety and regulatory approval. Engineers must consider fouling, material compatibility, and ongoing inspection to maintain optimal performance.

How to Select the Right Heat Exchanger for Your Application

Compare Main Types of Compact Heat Exchangers

Engineers can choose from several main types of compact heat exchangers. Each design offers unique features and serves different heat exchanger applications. The table below summarizes the most common types, their design features, and typical uses:

Type of Heat Exchanger | Design Features | Applications |

|---|---|---|

Double Pipe Heat Exchangers | Versatile, parallel or counterflow configurations, easy maintenance, economical | Chemical processing plants for cooling/heating |

Shell and Tube Heat Exchangers | Tubes within a cylindrical shell, high efficiency, modular structure | Power generation, oil refining, HVAC, food/beverage |

Plate Heat Exchangers | Stacked plates, large surface area, efficient heat exchange | HVAC systems, refrigeration, chemical processing |

Finned-Tube Heat Exchangers | Tubes with fins to enhance surface area, efficient heat transfer | HVAC systems, industrial processes |

Scraped Surface Heat Exchangers | Designed for high-viscosity fluids, continuous fouling removal | Food processing, pharmaceuticals, cosmetics |

Plate heat exchangers use stacked plates to maximize surface area. Finned-tube designs add fins to tubes for better heat transfer. Scraped surface models handle thick or sticky fluids. Each type has strengths for specific requirements.

Evaluate Performance, Cost, and Lifecycle

Selecting the right heat exchanger involves comparing performance, cost, and expected lifespan. Engineers look at heat transfer efficiency, pressure drop, maintenance needs, and total cost of ownership. The table below highlights key metrics for common designs:

Heat Exchanger Type | Initial Cost Range | Installation Cost % of Purchase Price | Operational Efficiency (U-values) | Maintenance Cost % of Purchase Price | Lifespan (Years) | Downtime for Maintenance (Days) |

|---|---|---|---|---|---|---|

Plate and Frame | $5,000 - $50,000 | 15-25% | 2,000 - 5,000 W/m²K | 5-10% | 15-25 | 1-3 |

Spiral | $15,000 - $100,000 | 25-40% | 1,000 - 3,000 W/m²K | 3-8% | 20-30 | 3-7 |

Performance depends on flow regime and sizing. Turbulent flow (Reynolds number above 4,000) gives high heat transfer but increases pressure loss. Designs with low pressure drop save energy but may reduce thermal efficiency. Maintenance costs and downtime also affect the total value over the equipment’s life.

Tip: Engineers should balance initial investment with long-term savings by considering both operational efficiency and maintenance needs.

Match the Right Heat Exchanger to Your Needs

To select a heat exchanger that is the best fit, engineers match process requirements to design features. The table below lists important factors to consider:

Factor | Description |

|---|---|

Type of Fluids | Consider if the fluids are liquids, gases, or corrosive materials. |

Temperature and Pressure | Assess the required operating conditions for optimal heat exchanger selection. |

Cooling Medium Availability | Determine the availability of cooling water or air for the heat exchanger type. |

Space Constraints | Evaluate the physical space available for installation to choose a compact solution. |

Maintenance & Cleaning Needs | Identify the frequency of cleaning required to select an appropriate design. |

Cost Considerations | Analyze initial investment versus lifecycle costs to make a financially sound decision. |

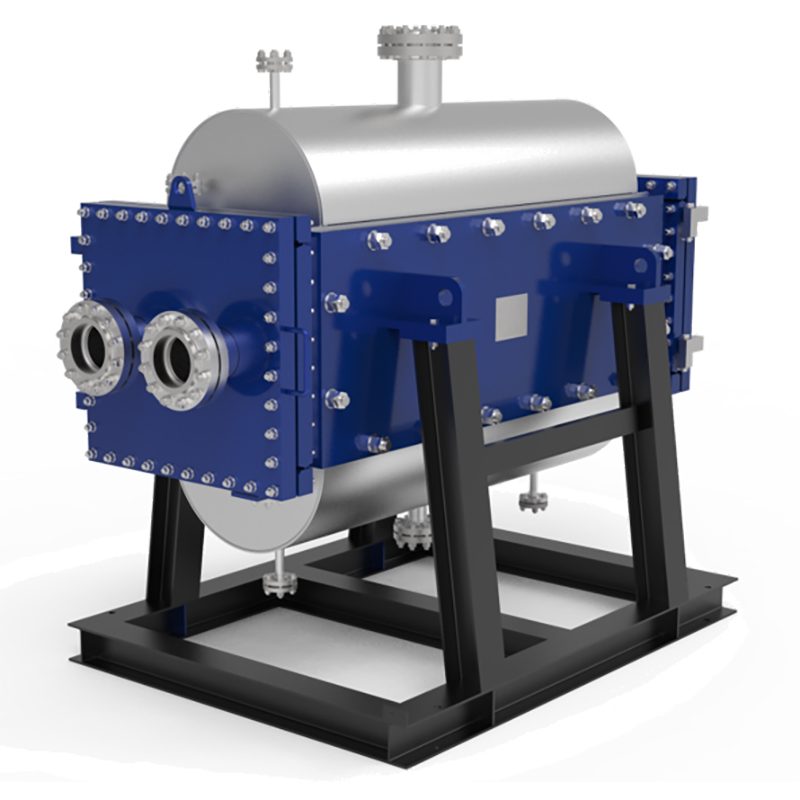

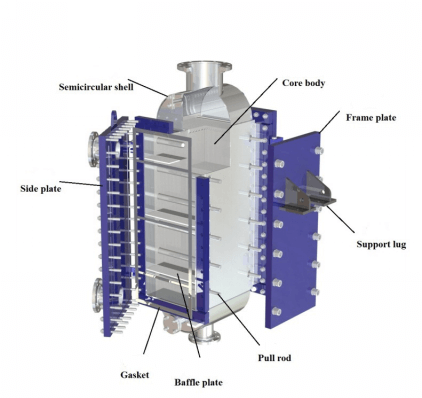

Sizing plays a key role in matching the heat exchanger to process needs. Engineers must check temperature, pressure, and flow rates. They also consider the physical space for installation. Compact designs work well in tight spaces and reduce installation costs. For challenging fluids or extreme conditions, welded plate heat exchangers like the TP Welded Plate Heat Exchanger from Shanghai Heat Transfer offer high durability and resistance to corrosion. This model handles a wide range of temperatures and pressures, making it suitable for demanding environments such as metallurgy, mining, and food processing.

Get Expert Support from Shanghai Heat Transfer

Shanghai Heat Transfer provides expert guidance for those who need to select a heat exchanger. Their engineers help with sizing, material selection, and compliance with industry standards. They recommend solutions based on process requirements and operational goals. The TP Welded Plate Heat Exchanger stands out for its robust construction, high heat transfer efficiency, and easy maintenance. Openable bolted connections allow for quick cleaning and inspection, which reduces downtime and supports long-term reliability.

Note: Consulting with Shanghai Heat Transfer ensures that every compact heat exchanger meets both technical and budget requirements.

Engineers who seek the best fit for their process can rely on Shanghai Heat Transfer’s experience and innovative products. Their support helps users achieve optimal sizing, efficiency, and performance for all heat exchanger applications.

Selecting the right compact heat exchanger starts with clear requirements and careful design choices. The table below highlights best practices from recent industry reports:

Key Takeaways |

|---|

Understanding compact heat exchanger technology |

Design and performance optimization |

Applications in HVAC, aerospace, and automotive |

Energy efficiency and environmental impact |

A checklist helps ensure compliance with industry standards. Shanghai Heat Transfer’s expertise and the TP Welded Plate Heat Exchanger support reliable decisions.

FAQ

What industries use compact heat exchangers?

Many industries use compact heat exchangers. These include oil and gas, chemical processing, food production, mining, and metallurgy.

How does the TP Welded Plate Heat Exchanger improve maintenance?

Openable bolted connections allow fast access. Workers clean and inspect the unit easily. This design reduces downtime and supports reliable operation.

What materials are available for the TP Welded Plate Heat Exchanger?

Shanghai Heat Transfer offers stainless steel, titanium, and Hastelloy. These materials resist corrosion and handle extreme temperatures and pressures.