Top Industries Revolutionizing Heat Exchange System Applications

Technology | Key Benefits |

|---|---|

Printed Circuit Heat Exchangers | Handles high pressure, delivers superior robustness |

Heat Exchange System Overview

Principles of Heat Exchanger Technology

A heat exchange system moves thermal energy from one fluid to another without mixing them. This process forms the backbone of many industrial operations. The core function of a heat exchanger is to maximize heat transfer while minimizing energy loss. Different principles drive this technology. Heat conduction allows energy to move through solid surfaces. Convection uses fluid movement and turbulence to boost heat transfer. Radiation plays a minor role but can be important in some designs. The pattern of fluid flow—parallel, counterflow, or crossflow—determines how efficiently the system works. Counterflow patterns often deliver the highest efficiency because they keep a large temperature difference between fluids.

Principle/Process | Description |

|---|---|

Heat Conduction | Transfer of heat from hot fluid to cold fluid through heat transfer surfaces. |

Convection | Friction and turbulence between fluids enhance heat transfer during flow. |

Radiation | Minor role in heat transfer, applicable in some heat exchangers. |

Fluid Flow Patterns | Determines efficiency; includes parallel flow, counterflow, and crossflow. |

Counterflow Efficiency | Most efficient pattern; maintains large temperature difference, enhancing heat transfer. |

Industrial Significance

Industries rely on heat exchangers to support critical processes. In the food and beverage sector, these systems handle pasteurization and cooling. The pharmaceutical industry uses them for precise temperature control and water purification. Chemical and petrochemical plants depend on industrial heat exchangers for heating, cooling, and refining. Power generation facilities use process heat transfer systems to optimize energy efficiency and reduce emissions. HVAC systems in buildings use heat exchangers for climate control and air quality management.

Industry | Application |

|---|---|

Food and Beverage Industry | Pasteurization, sterilization, and cooling of food products. |

Pharmaceutical Industry | Temperature control in manufacturing processes and water purification. |

Chemical and Petrochemical | Cooling, heating, and temperature control during chemical reactions and refining processes. |

Power Generation Industry | Heat transfer in steam turbines and cooling systems to optimize energy efficiency. |

HVAC Industry | Temperature regulation and air quality management in buildings. |

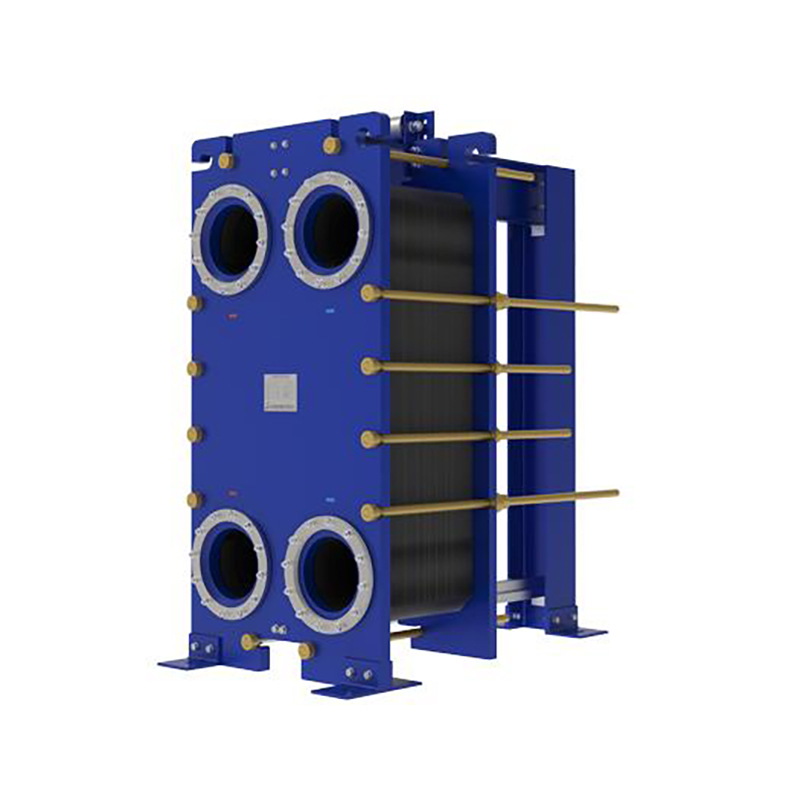

Shanghai Plate Heat Exchanger leads the heat transfer industry with high-efficiency equipment and innovative solutions. The Printed Circuit Heat Exchanger, developed by SHPHE, sets new standards for industrial cooling systems and heat recovery systems. Its compact design and advanced microchannel technology support waste heat recovery and energy savings across many applications. These advancements help industries achieve greater reliability, sustainability, and operational excellence.

Oil & Gas Industry Applications

Heat Exchanger Solutions in Oil & Gas

The oil and gas sector leads global installations of heat exchanger systems. This industry depends on reliable equipment to manage extreme operational demands. Shell and tube heat exchangers remain the most common choice for installations, supporting processes such as crude oil distillation, gas dehydration, and liquefied natural gas production. Industrial installations require robust solutions to handle high pressures and temperatures. Shell and tube heat exchangers provide durability and flexibility for installations in upstream, midstream, and downstream operations. Fin tube heat exchangers also play a vital role in installations, especially for air cooling and gas compression. These installations help maintain process stability and protect equipment from thermal stress.

Oil and gas installations often face harsh environments. Industrial installations must withstand corrosive fluids and abrasive particles. Shell and tube heat exchangers offer proven reliability for installations in refineries and offshore platforms. Fin tube heat exchangers support installations in compressor stations and gas processing plants. The industry values installations that minimize downtime and reduce maintenance costs. Shanghai Plate Heat Exchanger delivers advanced solutions for installations, improving operational efficiency and safety across industrial sites.

PCHE for Extreme Conditions

Printed Circuit Heat Exchangers (PCHE) have transformed installations in oil and gas industries. These heat exchanger systems excel in installations where extreme pressure and temperature challenge conventional designs. PCHEs outperform shell and tube heat exchangers in installations that demand compact size and high thermal efficiency. Industrial installations benefit from PCHEs constructed with corrosion-resistant alloys, ensuring long-term reliability.

PCHEs endure high pressures and temperatures in installations, making them ideal for oil and gas applications.

They deliver exceptional thermal efficiency for installations handling high-viscosity fluids.

PCHEs adapt to varying operational conditions in installations, responding to changes in inlet temperature.

Shanghai Plate Heat Exchanger has demonstrated expertise in industrial installations through successful projects. The following table highlights real-world installations in the oil and gas sector:

Project Type | Description |

|---|---|

Oil Refinery | Achieved an 80% reduction in equipment failure after adopting welded PHEs. |

Wastewater Treatment Plant | Cut annual maintenance costs by 40% using wide-gap PHEs, demonstrating efficiency in handling slurries. |

Industrial installations in oil and gas industries rely on shell and tube heat exchangers and fin tube heat exchangers for critical processes. PCHE technology from Shanghai Plate Heat Exchanger enhances installations by delivering superior performance and reliability. These advancements support energy conservation and operational excellence in demanding applications.

Chemical & Petrochemical Industry

Petrochemical Process Heat Exchangers

Heat exchangers play a vital role in the chemical and petrochemical industry. These industrial systems transfer heat between fluids without mixing, which is essential for regulating temperatures in chemical production. Shell and tube heat exchangers remain the backbone of many industrial applications. They support processes such as distillation, condensation, and cooling in petrochemical plants. Plate-fin heat exchangers also provide high thermal performance, especially in space-limited environments.

Industrial operations rely on heat exchangers to maintain stable operating conditions. They prevent overheating and ensure machinery runs efficiently. In chemical and petrochemical facilities, shell and tube heat exchangers help control reaction temperatures and safeguard equipment. These systems enhance process efficiency and reduce fuel consumption, leading to economic benefits and minimizing environmental impact.

Note: Plate-fin heat exchangers offer compact design and high thermal performance, making them ideal for chemical processing where space is limited.

Heat Exchanger Type | Industrial Application | Benefit |

|---|---|---|

Shell and Tube | Distillation, cooling, condensation | Robustness, reliability |

Plate-Fin | Chemical processing, heat recovery | Compact, high performance |

Efficiency and Safety Innovations

Energy efficiency innovations in heat exchanger technology have transformed industrial operations in the petrochemical sector. Modern shell and tube heat exchangers recover and reuse thermal energy, reducing energy waste and lowering operational costs. These advancements help industries meet environmental standards by optimizing heat recovery and minimizing emissions.

Shanghai Plate Heat Exchanger delivers custom solutions for the chemical and petrochemical industry. Their Printed Circuit Heat Exchanger technology provides high thermal performance and compact design, which is crucial for high-temperature processes. Stable operations are maintained, supporting productivity and safety in demanding environments.

Heat exchangers enhance energy efficiency by recovering thermal energy.

Shell and tube heat exchangers ensure stable operations and prevent equipment failure.

Innovations in design help industries achieve process optimization and meet safety requirements.

Industrial applications in chemical and petrochemical plants depend on reliable heat exchanger systems. These solutions support efficiency, safety, and sustainability across diverse operations.

HVAC and Climate Control

Heat Exchange System in HVAC

Heating, ventilation, and air conditioning systems rely on heat exchangers to regulate indoor climates and save energy. These systems transfer heat between air, water, or refrigerant, ensuring comfortable temperatures in homes, offices, and industrial facilities. Plate heat exchangers offer high efficiency and compact designs, making them popular in advanced HVAC applications. Shell and tube heat exchangers remain essential in commercial chillers and large-scale equipment, providing robust performance and reliability. Industries use evaporator and condenser coils in air conditioners and heat pumps to move heat with refrigerants. Primary and secondary heat exchangers in furnaces extract heat from combustion gases, improving energy efficiency and reducing fuel consumption.

Description | |

|---|---|

Primary Heat Exchanger | Transfers heat from combustion gases, found in all standard and high-efficiency furnaces. |

Secondary (Condensing) Heat Exchanger | Extracts additional heat from combustion gases, improving efficiency in high-efficiency furnaces. |

Plate Heat Exchanger | Uses thin metal plates for heat transfer, offering high efficiency, often used in advanced HVAC. |

Shell-and-Tube Heat Exchanger | Consists of tubes inside a shell, used in commercial chillers and large-scale HVAC equipment. |

Evaporator and Condenser Coils | Functions as heat exchangers in air conditioners and heat pumps, transferring heat using refrigerant. |

Shell and tube heat exchangers support critical HVAC operations by maintaining stable temperatures and protecting equipment from thermal stress. These technologies help industries achieve energy savings and reliable climate control.

Trends in Energy Management

Digitalization is transforming energy management in HVAC heat exchange system applications. Smart monitoring tools automate core processes, saving time and increasing efficiency. LiDAR scan technology records thousands of data points quickly, improving planning accuracy for installations. Digital documentation reduces costs and supports environmental protection by lowering paper consumption and CO2 emissions. Real-time digital platforms enhance customer interaction, allowing users to track orders and communicate instantly.

Benefit | Description |

|---|---|

Digital tools can save up to 12 hours per project by automating core processes. | |

Enhanced Precision | LiDAR Scan technology records over 800 data points quickly, improving planning accuracy. |

Cost Reduction | Digital documentation reduces spending on printed materials and physical archiving. |

Environmental Protection | Lower paper consumption decreases CO2 emissions and supports green technologies. |

Improved Customer Interaction | Digital platforms enhance communication, allowing real-time order tracking and inquiries. |

Industries benefit from these advancements by optimizing energy use and improving overall system performance. Smart monitoring and digital tools support efficient heat exchanger operations, helping companies meet sustainability goals and deliver reliable climate control.

Food & Beverage Industry

Heat Exchanger Use in Food Processing

Heat exchangers play a vital role in the food and beverage industry. They support pasteurization and sterilization, which are essential for destroying harmful microorganisms and ensuring food safety. These systems maintain precise temperatures during processing, helping preserve nutrients, flavor, and texture. Industries rely on heat exchanger technology to achieve consistent results in applications such as milk pasteurization, juice sterilization, and yogurt production.

Shanghai Plate Heat Exchanger delivers advanced solutions for food and beverage applications. Their equipment provides high thermal efficiency and compact design, which is crucial for space-limited facilities. The Printed Circuit Heat Exchanger maximizes energy recovery and reduces operational costs. Food and beverage producers benefit from reliable temperature control and improved product quality.

Tip: Effective heat exchanger systems help maintain ideal conditions for pasteurization and sterilization, supporting both safety and quality.

Benefit | Description |

|---|---|

Food Safety | Maintains ideal temperatures to destroy harmful microorganisms. |

Nutrient Preservation | Helps in preserving nutrients, flavor, and texture of food products. |

Energy Efficiency | Enhances energy efficiency by recovering and reusing heat, reducing operational costs. |

Sustainability | Contributes to lower carbon footprint and meets sustainability goals in food production. |

Safety and Sustainability

Hygienic design stands as a top priority in the food and beverage industry. Heat exchangers must feature smooth, crevice-free surfaces and hygienic welds to prevent contamination. Facilities choose materials that resist corrosion and biofilm formation, such as FDA-compliant 316L stainless steel. Regulatory compliance requires equipment built to ASME codes and sanitary guidelines, supporting FDA and USDA standards.

Cleanability ensures easy sanitation and reduces contamination risks.

Material compliance protects against acids and caustics found in food processing.

Regulatory compliance supports safe operations and meets industry requirements.

Sanitary design and FDA-approved coatings minimize compliance risks. Facilities that neglect proper monitoring may face severe penalties. Clean-in-place capabilities allow effective cleaning without disassembly. Expert setup ensures optimal heat treatment and sanitation.

Feature | Description |

|---|---|

Cleanability | Designed for easy cleaning and sanitation to prevent contamination. |

Material Compliance | Uses FDA-compliant 316L stainless steel and sanitary alloys that resist acids and caustics. |

Regulatory Compliance | Built to ASME codes and sanitary guidelines, supporting FDA and USDA requirements. |

Shanghai Plate Heat Exchanger leads the industry with hygienic heat exchanger solutions. Their designs support food safety, sustainability, and regulatory compliance, helping producers deliver safe and high-quality products.

Power Generation Sector

Heat Exchange System for Power Plants

The power generation industry depends on heat exchanger technology to improve efficiency and reduce emissions. Power plants use heat exchangers to transfer thermal energy between fluids, supporting steam production and cooling processes. These systems help facilities recover waste heat, which increases overall energy efficiency and lowers fuel consumption. Plate heat exchangers play a key role in modern power plants. Their compact design and high thermal performance allow operators to optimize heat transfer and minimize energy losses. By recovering and reusing waste heat, power plants can cut carbon emissions and support global sustainability goals. Innovations in heat exchanger design have made it possible for industries to meet stricter environmental standards while maintaining reliable operations.

Note: Advanced heat exchanger systems help power plants save energy and reduce their carbon footprint, supporting cleaner electricity production.

PCHE in Renewable and Nuclear Energy

Printed Circuit Heat Exchangers (PCHE) have become essential in renewable and nuclear energy applications. Their unique design offers several advantages over traditional exchangers, especially in demanding environments. PCHE units deliver exceptional thermal efficiency, which helps maximize energy recovery in advanced reactors and renewable installations. Their ultra-compact size makes them ideal for space-constrained settings, such as modular nuclear plants or offshore wind platforms. The all-welded construction ensures mechanical durability, allowing PCHEs to handle extreme pressures and temperatures without leaks or fatigue. Design flexibility enables engineers to customize PCHEs for specific duties, enhancing performance in diverse power generation industry projects.

Advantage | Description |

|---|---|

Exceptional thermal efficiency | Achieves effectiveness of 95–98%, surpassing typical shell-and-tube units, minimizing energy losses. |

Ultra-compact size | Occupies 80–90% less space than comparable exchangers, ideal for space-constrained applications. |

Extreme pressure/temperature capability | Handles conditions down to –196 °C and up to 850 °C, with pressures beyond 1,000 bar. |

Mechanical durability | All-welded design resists leaks and fatigue, suitable for aggressive fluids. |

Design flexibility | Custom-engineered for specific duties, allowing for various flow patterns and enhanced performance. |

Application in nuclear & power generation | Serves as compact steam generators or waste-heat recuperators in advanced reactors. |

Shanghai Plate Heat Exchanger leads the way in supplying PCHE solutions for the power generation industry. Their technology supports reliable, efficient, and sustainable energy production across nuclear and renewable sectors.

Automotive Industry

Heat Exchanger Applications in Vehicles

Automotive industries rely on heat exchanger technology to maintain optimal performance and safety. Vehicle cooling systems use radiators, oil coolers, and condensers to regulate engine and battery temperatures. These components prevent overheating, which protects engines and extends battery life in electric and hybrid vehicles. Modern heat exchangers support compact engine designs, allowing manufacturers to meet strict emission regulations and improve efficiency.

The following table highlights the roles of heat exchangers in vehicle cooling and manufacturing processes:

Evidence Description | Role in Vehicle Cooling and Manufacturing Processes |

|---|---|

Heat regulators maintain battery temperature ranges (15°C to 35°C) for li-ion batteries. | They prevent overheating, thus increasing battery life, which is crucial for hybrid vehicles. |

Radiators help maintain optimal engine temperatures. | They are essential for timely engine cooling, preventing overheating as engine designs become more compact and powerful. |

Moderate radiation heat management systems include radiators, oil coolers, and condensers. | These systems regulate engine temperatures, preventing overheating and ensuring efficient vehicle operation. |

Improvements in thermal management are driven by emission regulations. | Enhanced heat exchanger systems are increasingly adopted to comply with stringent environmental regulations, improving overall vehicle efficiency. |

Automotive manufacturers use heat exchangers in production lines to control process temperatures. This technology supports consistent quality and reduces energy consumption during manufacturing.

Trends in Electrification

Automotive industries continue to innovate with lightweight materials and electrification. Designers use advanced materials to optimize shapes for functionality while maintaining high strength and low weight. These materials allow cost-effective manufacturing for high-volume production, especially for electric motor housings.

Lightweight materials like aluminum enhance performance and reduce vehicle weight, which is crucial for energy efficiency in electric and hybrid vehicles.

The market shifts toward sustainability, leading to the development of eco-friendly heat exchangers.

Integration of AI in heat exchanger design optimizes functionality and improves thermal performance.

Electrification drives new applications for heat exchangers, supporting battery cooling and electric motor temperature management. These advancements help industries meet environmental standards and deliver reliable, energy-efficient vehicles.

Pharmaceutical Industry Solutions

Pharmaceutical Process Heat Exchangers

The pharmaceutical industry demands precise temperature control throughout manufacturing processes. Maintaining stable temperatures ensures product integrity and protects active pharmaceutical ingredients from degradation. Industries rely on heat exchanger technology to safeguard medication efficacy and patient safety. Even brief temperature deviations can reduce potency or force entire batches to be discarded. Stability data must remain intact from production to delivery, and any uncertainty about temperature history can result in significant financial losses.

Evidence Point | Description |

|---|---|

Product Integrity | Precise temperature control prevents degradation of active pharmaceutical ingredients and maintains the efficacy and safety of medications. |

Financial Impact | Cold chain failures can lead to significant financial losses, representing millions in wasted investment. |

Patient Safety | Minor temperature deviations can render medications ineffective or unsafe, jeopardizing patient treatment. |

Shanghai Plate Heat Exchanger provides advanced heat exchanger solutions for pharmaceutical manufacturing. Their Printed Circuit Heat Exchanger offers compact design and high efficiency, supporting critical applications such as vaccine production, fermentation, and purification. These systems deliver consistent temperature control, helping industries meet strict quality standards.

Temperature consistency is crucial; even brief deviations can reduce potency.

Any uncertainty about temperature history can force entire batches to be discarded.

Compliance and Precision

Pharmaceutical companies must meet rigorous regulatory compliance standards. Custom heat exchangers support sterile conditions and precise temperature control, which are essential for compliance with ASME and FDA sanitary standards. These systems use pure materials and undergo thorough testing for cleanliness. Heat exchangers facilitate Clean-in-Place cleaning, preventing cross-contamination and maintaining the purity of Water for Injection by controlling temperature during production. They also generate clean steam for sterilization and cleaning, which is vital for maintaining hygiene.

Clean-in-Place (CIP) Heating: Ensures effective cleaning without disassembly, reducing downtime and preventing fouling.

WFI Heating & Cooling: Maintains purity and prevents contamination during production.

Clean Steam Generation: Produces pure steam for sterilization and cleaning, essential for maintaining hygiene.

Shanghai Plate Heat Exchanger’s solutions help pharmaceutical industries achieve compliance and precision in their manufacturing processes. Their technology supports product quality, patient safety, and operational efficiency while optimizing energy use in critical applications.

Cross-Industry Trends

Sustainability in Heat Exchange Systems

Industries continue to prioritize sustainability in heat exchanger design. Companies now integrate renewable energy sources into their heat exchange system applications. Solar thermal collectors and ground-source heat pumps help reduce reliance on fossil fuels. These technologies minimize greenhouse gas emissions and support energy independence. Manufacturers also explore eco-friendly refrigerants to meet stricter regulations and promote greener practices. The adoption of smart technologies in heat exchanger systems improves operational efficiency and reduces environmental impact. These changes deliver environmental benefits and cost savings for businesses.

Tip: Sustainable heat exchanger solutions not only lower emissions but also increase resilience against market fluctuations.

Digitalization and Smart Monitoring

Digitalization transforms how industries manage heat exchanger performance. Digital twin technology enables real-time monitoring, allowing operators to adjust systems instantly based on performance data. Predictive maintenance forecasts service needs, helping companies avoid unnecessary downtime and energy waste. Continuous monitoring of key performance indicators supports informed decisions that optimize energy efficiency. These digital tools improve reliability and extend equipment lifespan. Shanghai Plate Heat Exchanger leads the industry by integrating smart monitoring features into their products, ensuring maximum efficiency and operational benefits.

Digitalization Benefit | Description |

|---|---|

Real-time Monitoring | Immediate adjustments based on system data |

Predictive Maintenance | Accurate forecasting of service needs |

KPI Tracking | Optimizes energy usage and system performance |

Integration with Renewables

The integration of heat exchanger systems with renewable energy sources presents new opportunities and challenges. Engineers design systems to capture, store, and distribute thermal energy from renewables, often using high energy density storage. Uniform flow across parallel channels in compact heat exchangers remains a technical challenge, sometimes causing hotspots and reduced efficiency. Integrating heat pumps into existing buildings is complex, especially compared to new construction. High raw material costs can impact initial installation expenses. Corrosion and fouling from liquid interactions and extreme temperatures affect all types of heat exchangers. Despite these challenges, Shanghai Plate Heat Exchanger continues to deliver solutions that maximize efficiency and environmental benefits for renewable applications.

Renewable integration supports cleaner energy and long-term sustainability.

Advanced heat exchanger designs help industries overcome technical hurdles and achieve reliable performance.

Industries continue to transform heat exchanger applications by prioritizing efficiency, sustainability, and innovation. Shanghai Plate Heat Exchanger and PCHE technology set new benchmarks for reliability and performance. Advancements in materials science and smart sensors will further enhance operational excellence. As energy demands grow, intelligent systems and eco-friendly solutions will shape the future. Collaboration across sectors promises smarter, greener, and more resilient industrial processes.

FAQ

What makes Printed Circuit Heat Exchangers (PCHE) unique?

PCHEs feature microchannel designs that maximize heat transfer efficiency. Their compact size allows installation in space-limited environments. The robust construction supports operation under extreme pressure and temperature.

Which industries benefit most from Shanghai Plate Heat Exchanger solutions?

Industries such as oil and gas, chemical processing, power generation, food and beverage, and pharmaceuticals rely on Shanghai Plate Heat Exchanger for reliable, efficient heat exchange systems.

How does PCHE technology support sustainability goals?

PCHEs recover and reuse thermal energy, reducing fuel consumption and emissions. Their high efficiency helps industries meet environmental standards and lower operational costs.

What safety features do heat exchangers offer in food and pharmaceutical applications?

Heat exchangers use hygienic materials and smooth surfaces to prevent contamination. Clean-in-place capabilities ensure easy sanitation. Regulatory compliance supports safe operations.

Can heat exchangers integrate with renewable energy systems?

Yes. Heat exchangers work with solar thermal collectors, ground-source heat pumps, and other renewable sources. This integration improves energy efficiency and supports sustainability initiatives.