What Makes Modern Pillow Plate Heat Exchangers More Efficient

What Makes Modern Pillow Plate Heat Exchangers More Efficient

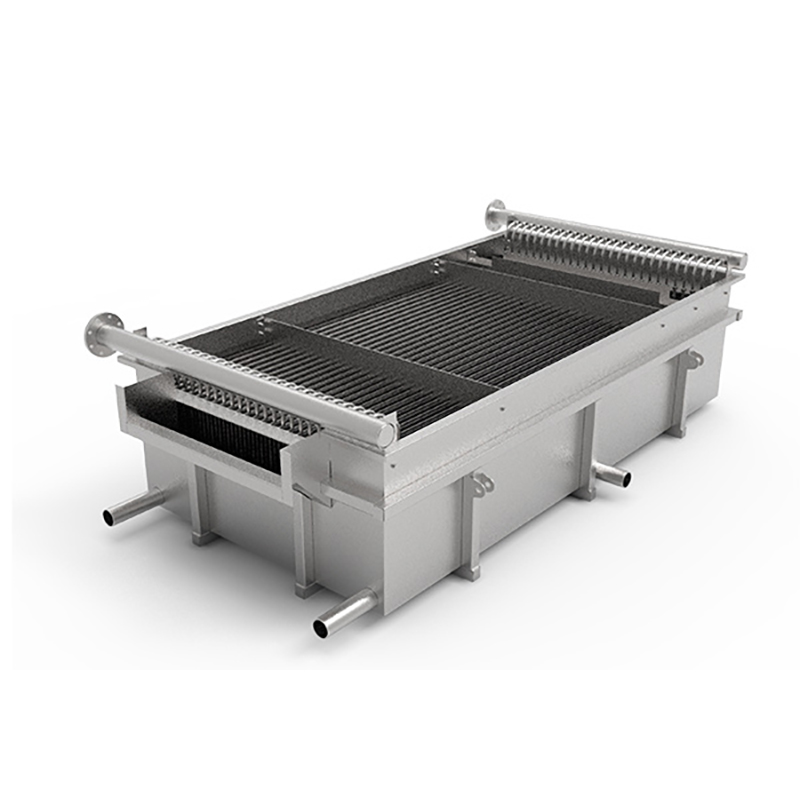

Modern pillow plate heat exchangers achieve higher efficiency through innovative internal cavity design, advanced materials, and digital integration. Shanghai Heat Transfer's Pillow Plate features laser-welded geometries and IoT monitoring, which support exceptional energy savings and durability. The product offers easy cleaning and adapts to many industries. Recent data shows an optimal JF increase of 2.23%–10.00%, while certified features ensure reliable performance.

Shanghai Heat Transfer’s Pillow Plate holds ASME, CE, and ISO certifications, making it a trusted solution for global industrial needs.

Pillow Plate Heat Exchanger Technology

Internal Cavity And Dimple Design

Pillow plate heat exchangers use a unique internal cavity and dimple design. This structure increases the surface area for heat exchange and eliminates gaps. Industries such as dairy rely on this technology for cooling milk, where easy cleaning and maintenance are essential. The dimpled internal structure promotes turbulence, which boosts convective heat transfer. The large surface area allows for a rapid thermal response. The geometry of pillow plate heat exchangers helps fluids mix better and reduces thermal resistance. These features make pillow plate heat exchangers more efficient than conventional exchangers, such as shell-and-tube or plate types, which often struggle with space and cleaning.

The dimpled design creates turbulence for better heat transfer.

The large surface area speeds up thermal response.

Unique geometry improves fluid mixing and lowers thermal resistance.

Fluid Versatility And Pressure Resistance

Pillow plate heat exchangers handle many types of fluids, including water, oil, and gas. The enclosed cavities support different operating conditions. The internal geometry, especially the recirculation zones, creates localized flow patterns that enhance mixing. Enhanced mixing leads to higher heat transfer rates. The optimized geometry maximizes the effective heat transfer area and keeps pressure losses low. These systems resist deformation and maintain performance under high pressure. Shanghai Heat Transfer’s Pillow Plate stands out for its ability to adapt to various fluids and challenging environments.

Internal geometry creates flow patterns for better mixing.

Improved mixing increases heat transfer rates.

Optimized design maximizes heat transfer area and minimizes pressure loss.

Recent Innovations In Pillow Plate Heat Exchangers

Advanced Geometries For Enhanced Efficiency

Recent innovations in pillow plate heat exchangers have transformed the way industries manage heat transfer. Engineers now use advanced geometries, such as wavy plates and ellipsoidal dimples, to increase the surface area and promote turbulence. These changes boost heat transfer rates and improve overall system performance. Studies show that the use of wavy plates and hybrid nanofluids can increase the Nusselt number by 12–42%. This means the exchangers transfer heat more efficiently. The pressure drop rises only slightly, about 10%, while the performance evaluation criteria (PEC) values remain above one. By decreasing the wavelength and increasing the wave amplitude, engineers have achieved PEC values as high as 1.8. These geometric enhancements help deliver uniform heat distribution and greater energy efficiency.

Shanghai Heat Transfer’s Pillow Plate stands out with its engineered dimple patterns and custom geometries. Their team provides engineering support to tailor each design for specific industrial needs. This approach ensures that every pillow plate heat exchanger delivers optimal performance, whether used in food processing, chemical manufacturing, or environmental systems.

Wavy plates and ellipsoidal dimples increase surface area.

Hybrid nanofluids further enhance heat transfer efficiency.

Custom geometries allow for application-specific solutions.

Efficiency Benefits Of Modern Pillow-Plates

Energy Savings And Sustainability

Modern pillow plate heat exchangers deliver significant energy savings. Their advanced systems use engineered dimple patterns and optimized internal cavities to maximize heat transfer. These features allow industries to recover and reuse energy, which reduces overall consumption. Operators see lower utility costs and improved sustainability. Shanghai Heat Transfer’s pillow plate heat exchangers support eco-friendly practices by enabling efficient heat recovery and minimizing waste. The design also helps companies meet environmental standards and reduce emissions. Many industries choose pillow plate heat exchangers for their ability to boost energy efficiency and support green initiatives.

Pillow plate heat exchangers recover and reuse energy.

Lower energy consumption leads to cost savings.

Efficient heat transfer supports sustainability goals.

Application Flexibility Across Industries

Pillow plate heat exchangers demonstrate remarkable flexibility in industrial applications. Researchers have evaluated 27 different configurations for energy storage and heat transfer rates, showing that these exchangers adapt to a wide range of processes. Industries such as brewing, food processing, chemical manufacturing, and environmental protection rely on pillow plate heat exchangers to optimize energy recovery and storage. The versatility of these systems allows operators to tailor solutions for specific needs. Shanghai Heat Transfer’s pillow plate heat exchanger supports diverse applications, making it a preferred choice for companies seeking reliable and efficient heat transfer.

Pillow plate heat exchangers adapt to many industries.

Operators can customize systems for unique processes.

Versatility supports energy recovery and process optimization.

Industrial Applications And Real-World Results

Food And Beverage Processing

Food and beverage companies rely on pillow plate heat exchangers to improve efficiency and product quality. These exchangers deliver rapid and uniform heat exchange, which helps maintain consistent temperatures during pasteurization and cooling. Operators benefit from easy cleaning and sanitization, which supports strict hygiene standards. Shanghai Heat Transfer’s pillow plate heat exchangers offer corrosion resistance and a long service life, reducing maintenance costs. The table below highlights key features and benefits in this sector:

Feature | Benefit |

|---|---|

High exchange efficiency | Enhances heat transfer, improving efficiency |

Reduction of energy requirement | Lowers operational costs |

Simplicity of cleaning and sanitization | Ensures product quality and safety |

Long service life and corrosion resistance | Reduces maintenance and replacement costs |

Many food processors choose these exchangers for their compatibility with different fluids and their ability to save energy.

Chemical And Pharmaceutical Manufacturing

Chemical and pharmaceutical manufacturers use pillow plate heat exchangers for processes that demand high cleanliness and efficiency. These exchangers reduce energy consumption by up to 30% compared to older systems. Superior thermal efficiency boosts overall process performance. Shanghai Heat Transfer’s pillow plate heat exchangers provide a longer lifecycle, which means fewer replacements and lower costs. Enhanced cleanability helps companies meet strict industry regulations. The table below shows important performance metrics:

Performance Metric | Description |

|---|---|

Energy Consumption Reduction | Reduces energy consumption by up to 30% compared to traditional systems. |

Thermal Efficiency | Offers superior thermal efficiency, enhancing overall process performance. |

Lifecycle | Provides a longer lifecycle, reducing the need for frequent replacements. |

Cleanability | Enhanced cleanability, crucial for compliance in pharmaceutical and food sectors. |

These applications of pillow plate heat exchangers drive demand in food, beverage, and pharmaceutical sectors.

Environmental And HVAC Solutions

Environmental and HVAC systems use pillow plate heat exchangers for efficient heating and cooling. These exchangers support sanitary and energy-efficient operations in dairy, brewing, and pharmaceutical applications. Operators install them in tanks for cooling or heating, which helps maintain stable temperatures and reduces energy use. The table below lists common applications and advantages:

Applications | Advantages |

|---|---|

Dairy | Sanitary |

Brewing | Strong |

Pharmaceuticals | Energy-efficient |

Tanks for cooling/heating | Versatile |

These exchangers adapt to many industrial applications, offering reliable performance and energy savings.

FAQ

What industries use pillow plate heat exchangers?

Many industries use pillow plate heat exchangers. Food and beverage, chemical, pharmaceutical, and environmental sectors rely on them for efficient heat transfer. These exchangers adapt to different fluids and processes, making them a flexible choice for many applications.

How does Shanghai Heat Transfer ensure product quality?

Shanghai Heat Transfer uses certified materials and advanced manufacturing methods. Their pillow plates meet ASME, CE, and ISO standards. The company provides engineering support to help clients achieve the best results.

What makes pillow plate heat exchangers easy to clean?

The smooth surfaces and unique dimple design allow for simple cleaning. Operators can use ultrasonic cleaning systems to remove deposits. This feature helps maintain hygiene and reduces downtime.

Can pillow plate heat exchangers handle high pressure?

Yes. The internal structure resists deformation and supports high-pressure operations. This durability makes them suitable for demanding environments.