Core Power Choice: PCHE Enables High-Efficiency Upgrades in Supercritical CO₂ Brayton Cycles

Under the guidance of global carbon peaking and carbon neutrality goals, supercritical carbon dioxide (S-CO₂) Brayton cycle power generation technology, with its high thermal efficiency, compact system design, and low water consumption, has become a central focus of the energy transition. The Printed Circuit Heat Exchanger (PCHE), as the key heat exchange component of this cycle, directly determines the system’s performance and commercial value. This article analyzes the cycle’s process flow, explains the limitations of traditional heat exchangers in this application, and demonstrates the core technical advantages of PCHE.

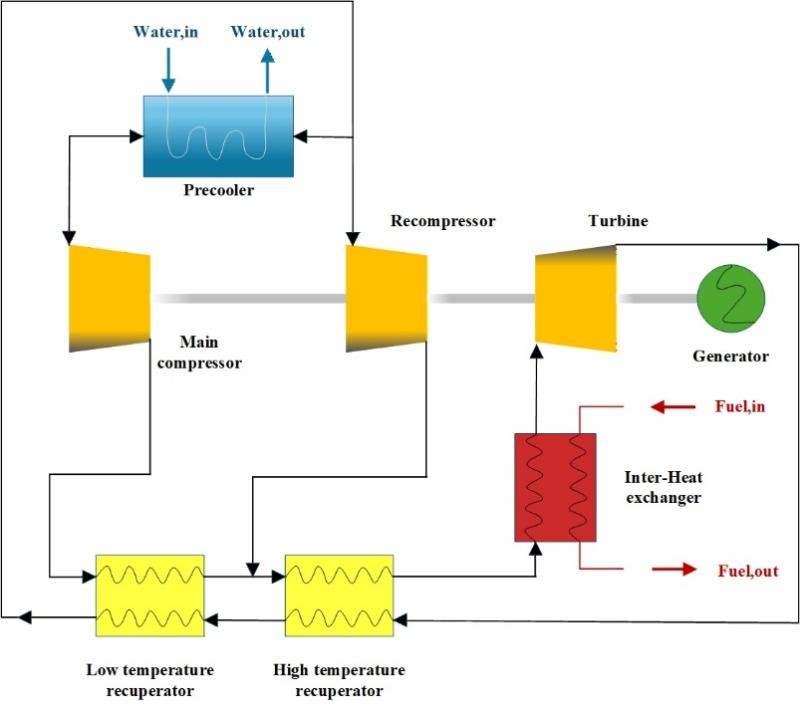

1. Supercritical CO₂ Brayton Cycle Power Generation Core Process

The system uses supercritical CO₂ as the working fluid and achieves efficient conversion of heat to electricity through a closed-loop cycle with no gas–liquid phase change in the traditional sense. The cycle comprises six key stages: the low-temperature, low-pressure working fluid (33 °C, 8.1 MPa) is compressed by a compressor to 20–23 MPa. It then passes sequentially through a low-temperature recuperator and a high-temperature recuperator to recover waste heat and raise its temperature. Next, it is heated by a heater (using heat sources such as industrial waste heat or solar thermal energy) to 500–800 °C and enters a turbine-generator set to perform work and generate electricity. Finally, it is cooled by a cooler back to its initial state, completing the cycle. Research data shows that when the turbine inlet temperature exceeds 550 °C, the cycle’s thermal efficiency is 20%–50% higher than that of a traditional steam Rankine cycle, and water usage is reduced by 50%. The recuperators and cooler handle over 90% of the heat exchange duty, making them critical to the system’s efficient operation.

2. Limitations of Traditional Heat Exchangers

Supercritical CO₂ cycle conditions are characterized by high pressure (8–23 MPa, reaching above 30 MPa at the upper end), high temperature (500–800 °C), rapidly changing fluid properties, and small temperature differentials for heat exchange. Traditional heat exchangers struggle to accommodate these conditions. Shell-and-tube heat exchangers require significantly thickened walls under high pressure, and a 50 MW-class recuperator of this type can reach a volume of several hundred cubic meters, over five times that of a PCHE, resulting in a very large footprint. Plate-fin heat exchangers have brazed seams that are prone to leakage and a maximum pressure tolerance of under 15 MPa, which cannot meet the requirements of medium and high-pressure systems. In addition, traditional exchangers also tend to have low heat transfer coefficients and large pressure drops, accounting for over 60% of total system pressure loss. According to estimates, this can lead to a 3–5 percentage point drop in net efficiency for a 10 MW-class system. Furthermore, with a specific surface area below 500 m²/m³, traditional heat exchangers fail to meet the system's compact integration needs.

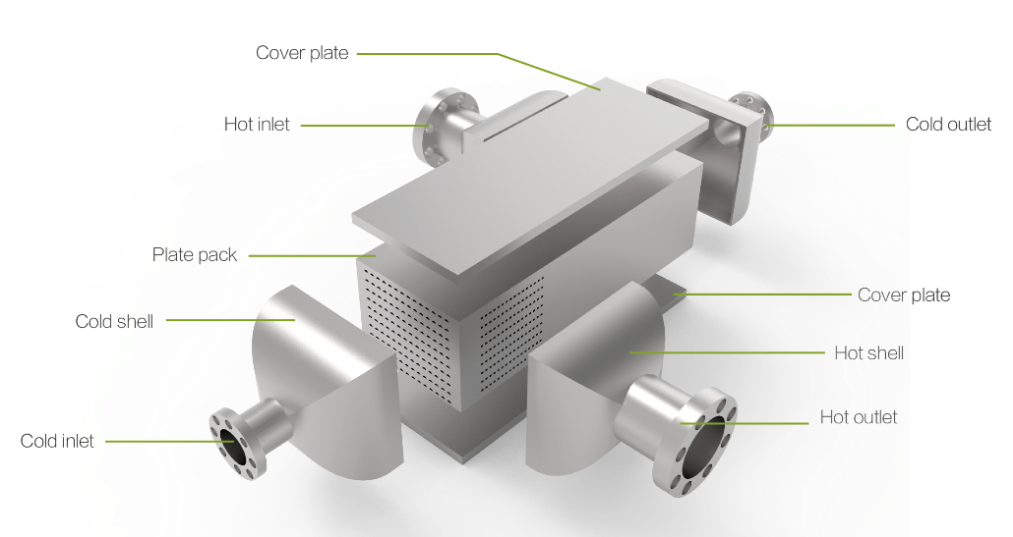

3. Core Technical Advantages of PCHE

PCHEs are fabricated using a combination of chemical etching and vacuum diffusion bonding technologies, coupled with their microchannel design (typically 0.1–2 mm) which makes them highly suitable for the demanding operating conditions of supercritical CO₂ systems. The core technical advantages include:

Exceptional Pressure and Temperature Resistance

PCHEs can withstand pressures up to 100 MPa and temperatures exceeding 800 °C, ensuring stable and leak-free operation under extreme high-pressure and high-temperature conditions.

Ultra-High Heat Transfer Efficiency

PCHEs offer ultra-high heat transfer efficiency, with heat transfer coefficients ranging from 2000–5000 W/(m²·K), which is 2–4 times that of conventional heat exchangers. The approach temperature differences can be as low as 2–3 K. In megawatt-scale systems, PCHE recuperators can achieve up to 95% effectiveness, resulting in a thermal efficiency improvement of 20%–25%.

Low Pressure Drop and Enhanced Energy Efficiency

The pressure drop across PCHEs is only 1/3–1/2 that of traditional exchangers. For a 10 MW-class system, this results in a 6%–8% reduction in total system pressure losses and an increase of 2–3 percentage points in net power output.

Highly Compact and Lightweight Design

PCHEs feature a specific surface area greater than 2500 m²/m³, which allows their volume to be just 1/4–1/6that of equivalent shell-and-tube exchangers. Their significantly lower weight also facilitates easier system integration.

Excellent Material Flexibility

PCHEs can be custom-manufactured using stainless steel, nickel-based alloys, and other suitable materials. This ensures reliable performance under rapidly changing fluid properties and compatibility with various working environments.

4. Conclusion

Currently, PCHE products manufactured by Shanghai Plate Heat Exchange Equipment Co., Ltd. (SHPHE) have met the needs of supercritical CO₂ Brayton cycle systems for core heat exchange components, including the high-temperature recuperator, low-temperature recuperator, and precooler. These units can adapt to the supercritical CO₂ working fluid’s harsh operating conditions of high pressure, high temperature, and widely varying properties, while delivering excellent heat transfer performance, controllable pressure drop losses, and strong adaptability to changing conditions. Shanghai Plate Heat Exchange Equipment Co., Ltd. (SHPHE) can provide customized solutions to help your project achieve higher thermal efficiency, lower energy consumption, and optimized costs. Choosing PCHE means choosing an efficient, reliable, and low-carbon energy future.