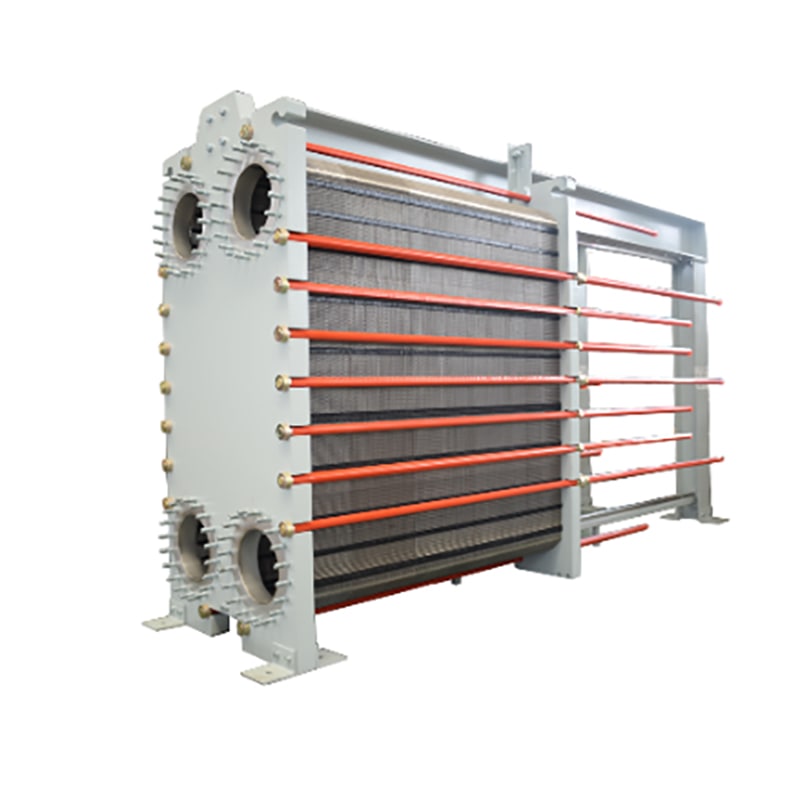

Heat Exchange Solutions for Metallurgy Industry

Metallurgy industry is a critical sector for raw material production, often referred to as the “backbone of industry.” It is generally divided into ferrous metallurgy, which includes iron and steel production, and non-ferrous metallurgy, which involves the processing of metals such as copper, aluminum, lead, zinc, nickel, and gold.

Addressing Your Needs with Tailored Solutions

Common failures of heat exchangers in the metallurgical industry include: decreased heat transfer efficiency (due to scaling, parameter deviations, or poor sealing), corrosion damage (erosion of process fluids causing thinning or perforation of tube walls), leakage issues (aging or improper installation of sealing components), vibration problems (excessive flow velocity or inadequate support), and blockage issues (accumulation of impurities affecting flow). To address these problems, We have implemented a comprehensive set of measures to ensure the efficient, reliable, and stable operation of heat exchangers.

-

Core Patents

Using the company's core patent technology, different types of products can be recommended according to different ore raw materials. -

Reduce Abrasion

We utilize corrosion-resistant materials and advanced monitoring systems to proactively address potential failures and extend the lifespan of the equipment. Maximize cleaning cycle and reduce abrasion. -

Smart Eye Monitoring

Using smart eye digital products, health prediction, energy efficiency diagnosis and cleaning effect evaluation of heat exchangers can be performed online. -

Extend Service Life

Use machine learning technology to recommend the best operating conditions and extend service life.

Your Needs, Our Priority

contact usPractical Applications in Metallurgy Industry

-

(1) Iron and Steel Smelting

Blast Furnace Gas Preheating: Plate heat exchangers are used to preheat blast furnace gas, improving its utilization efficiency and providing a stable heat source for subsequent processes.

Cooling in Hot Rolling Processes: During hot rolling, plate heat exchangers facilitate rapid cooling of hot steel billets through heat exchange with cooling fluids, enhancing the hardness and strength of the steel.

Cooling in Slag Treatment: The slag generated during metallurgical processes is rapidly cooled using plate heat exchangers, making it easier for subsequent handling and utilization. -

(2) Non-Ferrous Metal Smelting

Heating or Cooling of Aluminate Liquor: Plate heat exchangers are used to heat or cool aluminate liquor, ensuring temperature control during the smelting process.

Cooling of Electrolyte: In the electrolysis of non-ferrous metals, plate heat exchangers are employed to cool the electrolyte, maintaining process stability. -

(3) Mining

Heat Exchange of Slurry, Mine Water, and Coal Washing Water: In mining processes, plate heat exchangers are used for heat exchange of slurry, mine water, and coal washing water, improving thermal energy utilization.

Heat Exchange of Ultra-Fine Grinding Products: In ultra-fine grinding processes, plate heat exchangers facilitate heat exchange, optimizing production efficiency and product quality. -

(4) Other Fields

Melting, Refining, and Heat Treatment of Metals: Plate heat exchangers help regulate and control temperatures during the melting, refining, and heat treatment of metals, ensuring the processes meet the required conditions.

Thermal Energy Utilization in Alumina Production: In alumina production, plate heat exchangers are used for heat recovery, enhancing energy efficiency.

Service

Shanghai Heat Transfer Board Replacement Parts Warehouse can provide various original accessories at any time to ensure product quality. At the same time, the Shanghai board can open a spare parts query interface to check inventory or issue spare parts plans anytime and anywhere, ensuring timely delivery.

more details

Who Are We?

Shanghai Heat Transfer Equipment Co., Ltd.(SHPHE) specializes in the design, manufacturing, installation, and service of plate heat exchangers and complete heat transfer systems.

more details

To Provide You with Better Service

Honor Our Common Journey,Develop Authentic Alliances,Create Collective Success.

Leave Your Message

* Full Name

* Country/Region

* Email

* Company name

* Telephone Number

* Enter your needs

SHPHE has complete quality assurance system from design, manufacturing, inspection and delivery. It is certified with ISO9001, ISO14001, OHSAS18001 and hold ASME U Certificate.