"Smart Eye" - Intelligent Guardian Expert for Heat Exchangers

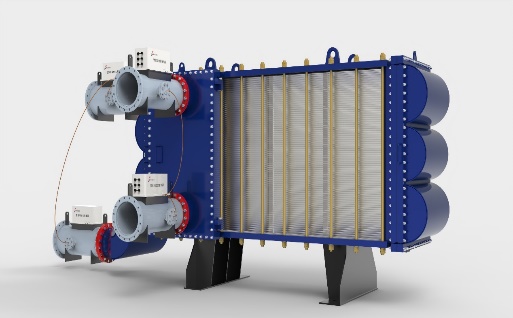

In industrial production, the stable operation of heat exchangers is directly related to production efficiency and energy security. As a globally leading heat exchanger manufacturer, Shanghai Plate Heat Exchanger has pioneered the "Smart Eye" digital monitoring system. This system, centered on artificial intelligence, edge computing, and digital twin technologies, provides global customers with full lifecycle intelligent operation and maintenance solutions, ensuring that every heat exchanger maintains enduring vitality.

Addressing Your Needs with Tailored Solutions

-

(1) Precision Real-Time Monitoring: The "Hyper-Sensory Nervous System" of Industrial Equipment

The "Smart Eye" is equipped with military-grade multi-source sensing arrays, utilizing 12 types of high-precision sensors (temperature, pressure, vibration, flow rate, etc.) to collect data in real time. With microsecond-level sampling frequency, it captures the slightest changes in equipment operation. Whether in high-temperature, high-pressure environments of chemical pipelines or complex working conditions of power systems, the system constructs a high-density monitoring network, providing a reliable data foundation for equipment health assessment. -

(2) Intelligent Analysis and Early Warning: The AI-Driven "Fault Prophet"

Based on a self-developed AI thermal model cluster, the "Smart Eye" compares real-time data with a multi-million historical working condition database through multi-dimensional analysis. Utilizing deep learning dynamic compensation algorithms, it achieves:

Precision Anomaly Detection: ±0.5°C temperature field reconstruction accuracy, promptly locating issues such as tube blockage and leakage.

Proactive Prediction: Predicting tube corrosion tendencies 30 days in advance, quantifying heat exchange efficiency decline trends to prevent potential failures.

Intelligent Diagnosis: Built-in knowledge graph of 150+ fault modes, combined with an expert experience database, automatically generates maintenance plans, shifting from reactive response to proactive prevention. -

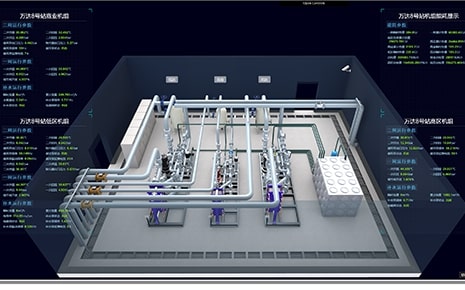

(3) Data Visualization and Decision Support: The "Smart Brain" for Comprehensive Control

The system features a unique 3D visualization dashboard, integrating thermal maps, energy efficiency radar charts, lifespan prediction curves, and other multi-dimensional interfaces, supporting cross-platform access via mobile/PC:

Real-Time Situational Awareness: Global thermal distribution is clear at a glance, with anomalies automatically highlighted.

Energy Efficiency Optimization Suggestions: Dynamic analysis based on historical data provides energy-saving renovation paths and equipment upgrade solutions.

Maintenance Decision Support: Automatically generates spare parts lists, maintenance cycle plans, and cost-benefit analysis reports, aiding management in scientific decision-making. -

(4) Seamless Integration and Remote Control: The "Universal Interface" Breaking Information Silos

The "Smart Eye" adopts an open architecture design, seamlessly integrating with existing SCADA, MES, and other systems to achieve data interoperability and collaborative management. Through IoT technology, users can remotely monitor equipment status anytime, anywhere via mobile or cloud platforms. Even when off-site, they can access real-time operating parameters and receive early warning notifications, eliminating reliance on on-site presence. -

(5) Empowering Digital Transformation: The "Acceleration Engine" for Cost Reduction and Efficiency Improvement

Reduced Maintenance Costs: Predictive maintenance minimizes unplanned downtime losses, saving over 20% in annual maintenance costs.

Enhanced Equipment Efficiency: Optimized thermal matching strategies achieve an average energy-saving rate of 12%, with overall equipment efficiency increasing by 23%.

Building Digital Assets: Accumulating full lifecycle data of equipment provides data support for process improvement and equipment upgrades, accelerating enterprise intelligent transformation. -

(6) Wide Applicability: The "All-Round Guardian" for Multiple Industries

The "Smart Eye" has been successfully applied in over 10 leading enterprises across industries such as chemicals, metallurgy, HVAC, and food processing, preventing 17 major and minor incidents and safeguarding the safe operation of more than 10,000 heat exchange equipment globally. Whether dealing with high-temperature, high-pressure oil refining units or complex central air conditioning systems, the "Smart Eye" can be customized to provide precise protection.

Choosing "Smart Eye" is not just selecting a monitoring tool but embedding an "industrial-grade intelligent eye" into your core production line. With 20 years of heat exchanger manufacturing experience as the foundation and technological innovation driving the maintenance revolution, we help you achieve a comprehensive leap from equipment control to energy optimization.

Your Needs, Our Priority

contact usService

Shanghai Heat Transfer Board Replacement Parts Warehouse can provide various original accessories at any time to ensure product quality. At the same time, the Shanghai board can open a spare parts query interface to check inventory or issue spare parts plans anytime and anywhere, ensuring timely delivery.

more details

Who Are We?

Shanghai Heat Transfer Equipment Co., Ltd.(SHPHE) specializes in the design, manufacturing, installation, and service of plate heat exchangers and complete heat transfer systems.

more details

To Provide You with Better Service

Honor Our Common Journey,Develop Authentic Alliances,Create Collective Success.

Leave Your Message

* Full Name

* Country/Region

* Email

* Company name

* Telephone Number

* Enter your needs

SHPHE has complete quality assurance system from design, manufacturing, inspection and delivery. It is certified with ISO9001, ISO14001, OHSAS18001 and hold ASME U Certificate.