How different heat exchanger types are applied across major industries

Plate heat exchangers are becoming more popular be...

More

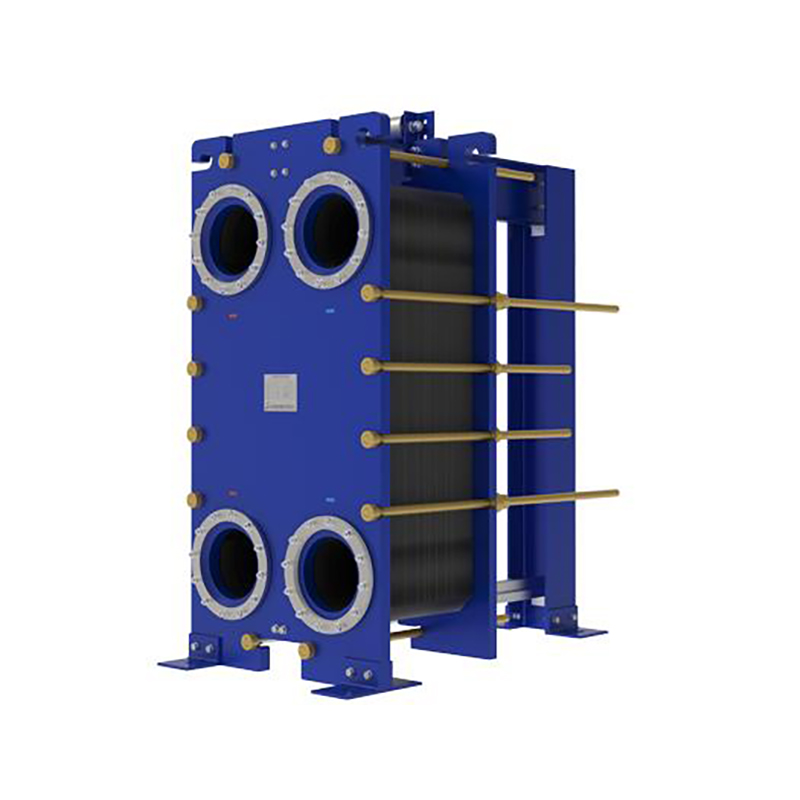

The industrial sector utilizes a wide range of exchanger types, including shell and tube, plate, air-cooled, and spiral heat exchangers, each designed for specific operational requirements. Shell and tube exchangers dominate the market, accounting for over 60% of global demand due to their versatility in high-pressure and high-temperature applications. Plate exchangers, known for their compact design and efficiency, are increasingly popular in food processing and HVAC systems, with a projected CAGR of 6.2% from 2023 to 2030. Air-cooled exchangers are favored in water-scarce regions, while spiral exchangers excel in handling viscous fluids and slurries.

Selecting the right exchanger type depends on factors like thermal efficiency, space constraints, and fluid compatibility. For instance, plate exchangers offer 90% thermal efficiency but are unsuitable for particulate-laden fluids. Recent advancements include hybrid exchangers combining multiple technologies, such as shell-and-plate designs, to optimize performance. Market data indicates the global heat exchanger market will reach $28.8 billion by 2027, driven by energy efficiency regulations and industrial automation. Case studies from oil refineries show that upgrading to modular plate exchangers can reduce energy consumption by 15-20%. Always consult engineering standards like ASME and TEMA when evaluating exchanger types for your application.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchangers are becoming more popular be...

More

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

API 662 defines standards for plate heat exchanger...

More

Compare top frame plate heat exchanger models for ...

More

User reviews show the american standard heat excha...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe plate heat exchanger is incredibly efficient and easy to maintain. Perfect for our industrial applications!

Emily Johnson

HVAC TechnicianThe shell and tube exchanger works flawlessly in our commercial HVAC systems. Highly recommend for energy savings!

David Lee

Process EngineerThe spiral heat exchanger exceeded our expectations in chemical processing. Durable and low maintenance!

Sarah Williams

Plant ManagerThe air-cooled exchanger is ideal for our food processing plant. Compact design and excellent performance!