Leakage free air preheater picks that stop waste now

Leakage free air preheater solutions from top bran...

More

Air preheaters are critical components in industrial and power generation systems, designed to improve thermal efficiency by recovering waste heat from flue gases. The primary types of air preheaters include regenerative (rotary and stationary), recuperative (tubular and plate), and heat pipe air preheaters. Each type offers distinct advantages depending on the application, such as reducing fuel consumption, lowering emissions, and enhancing boiler efficiency.

Regenerative air preheaters, particularly rotary designs, dominate the market due to their high efficiency and compact footprint. According to industry reports, rotary regenerative preheaters can achieve thermal efficiencies of up to 90%, making them ideal for large-scale power plants. Tubular recuperative preheaters, on the other hand, are favored in smaller installations for their simplicity and low maintenance. Heat pipe preheaters are gaining traction in corrosive environments due to their leak-proof design. Market data indicates a growing demand for advanced air preheaters, driven by stricter environmental regulations and the need for energy-efficient solutions. Choosing the right type depends on factors like operating temperature, space constraints, and cost considerations.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Leakage free air preheater solutions from top bran...

More

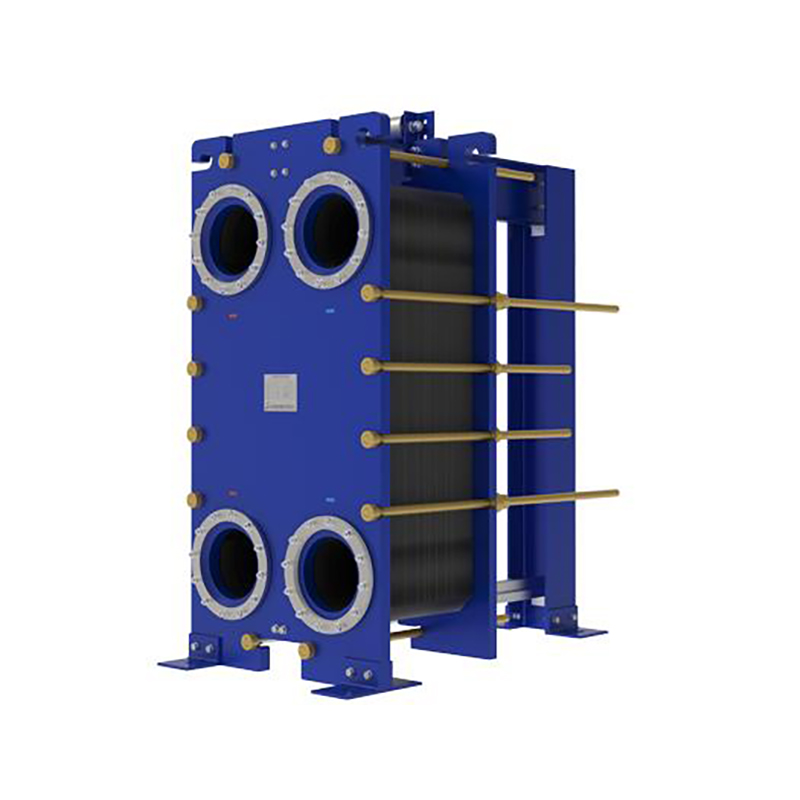

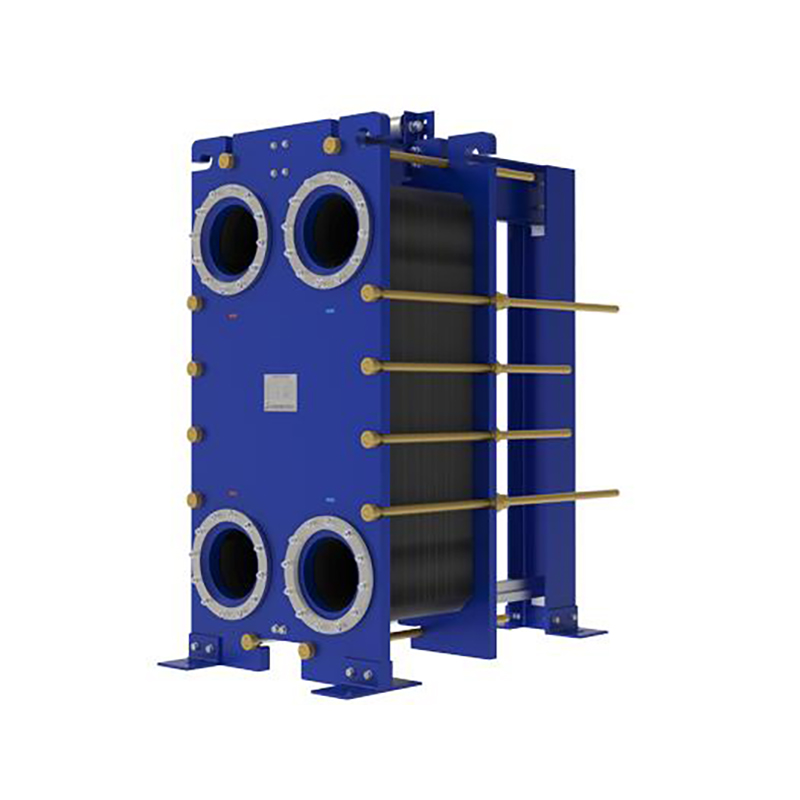

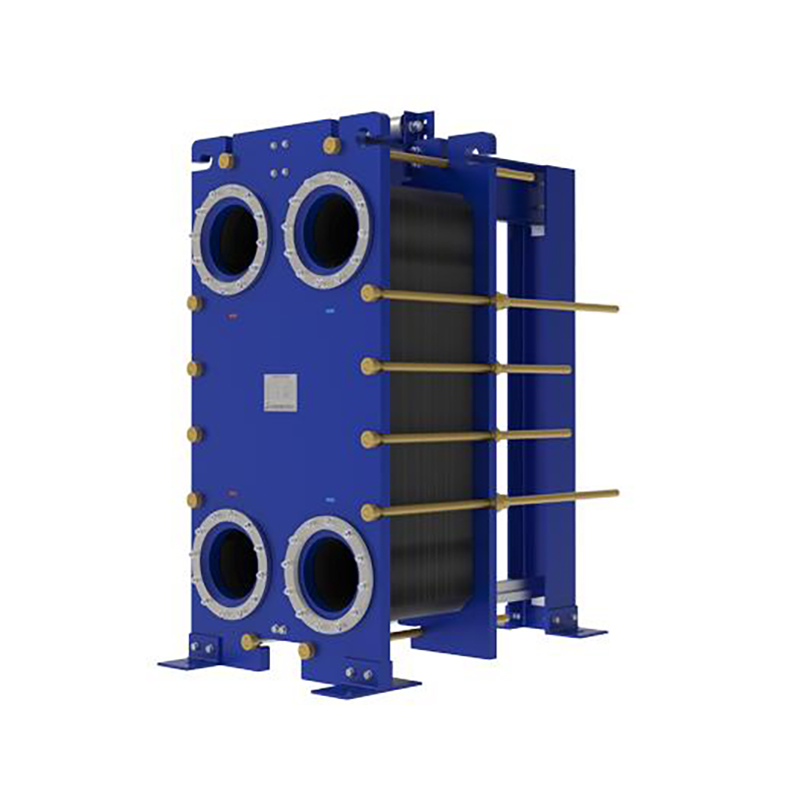

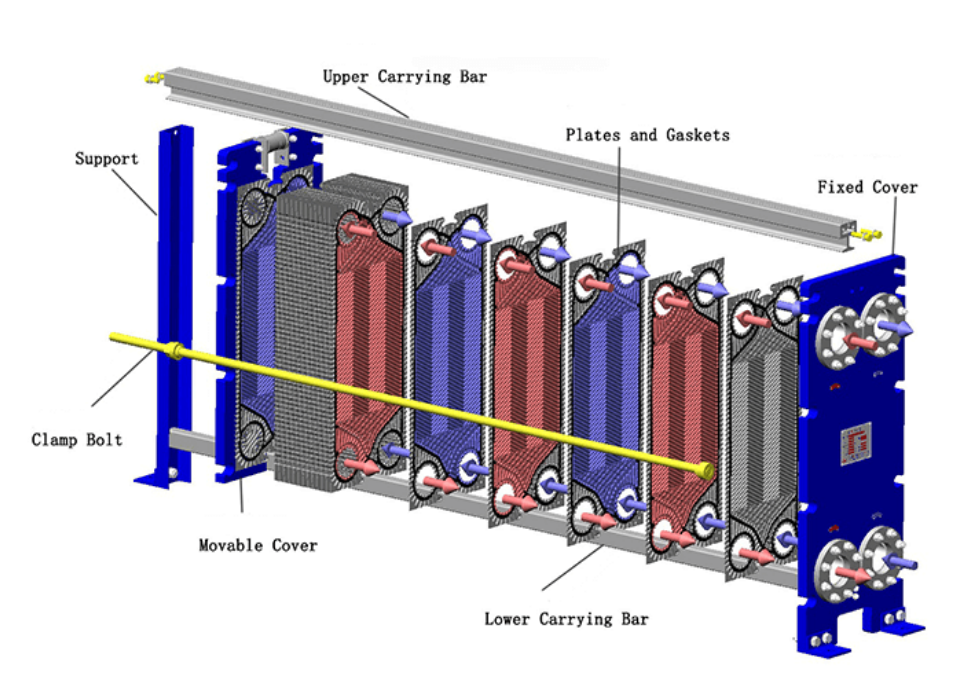

Compare top frame plate heat exchanger models for ...

More

Plate heat exchangers are becoming more popular be...

More

Plate heat exchangers boost industrial energy effi...

More

Gasketed plate heat exchangers boost industrial ef...

More

Plate heat exchangers cut industrial energy use, l...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe regenerative air preheater we purchased has significantly improved our plant's efficiency. Highly recommended for power generation applications!

Emily Johnson

Process EngineerThe rotary air preheater works flawlessly in our chemical processing unit. Minor maintenance required, but overall excellent performance.

Michael Brown

Plant ManagerThe tubular air preheater exceeded our expectations in durability and heat recovery. Perfect for cement manufacturing environments.

Sarah Davis

HVAC SpecialistInstalled a plate-type air preheater in our commercial facility. Energy savings are noticeable, though installation was slightly complex.