5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

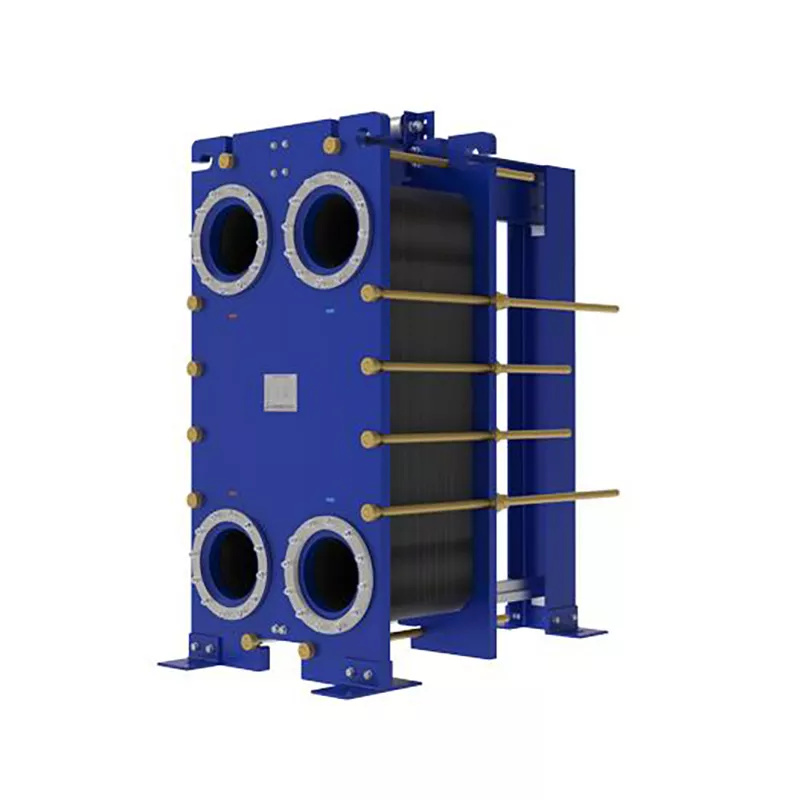

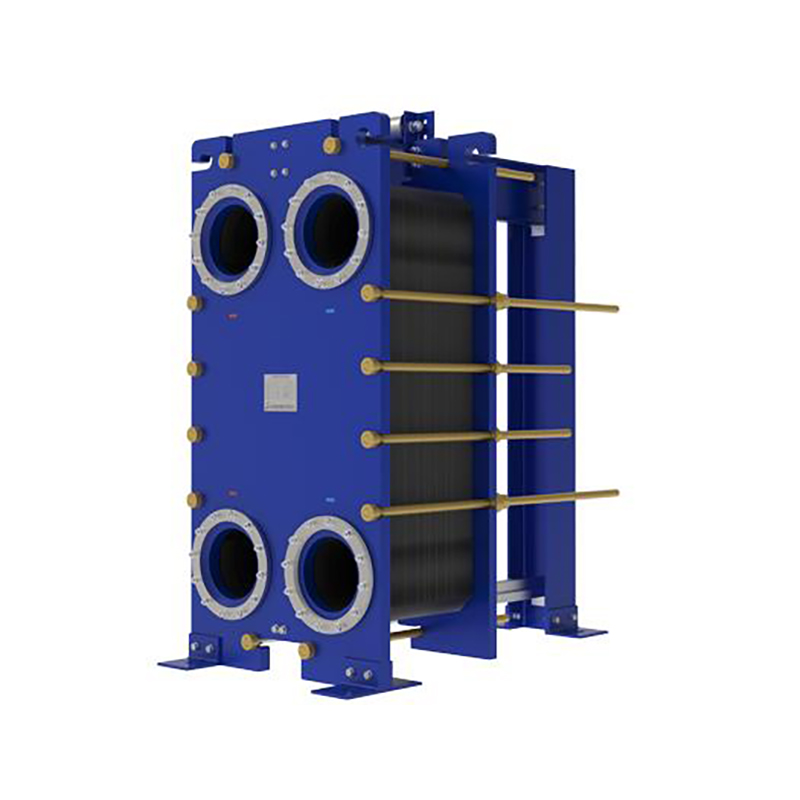

Heat exchangers are critical components in the oil and gas industry, enabling efficient heat transfer between fluids to optimize processes like refining, petrochemical production, and gas processing. There are several types of heat exchangers commonly used in this sector, each designed for specific applications and operational conditions. The most prevalent types include shell-and-tube, plate-and-frame, air-cooled, and spiral heat exchangers. Shell-and-tube exchangers dominate the market due to their durability and high-pressure tolerance, while plate-and-frame exchangers are favored for their compact design and superior thermal efficiency. Air-cooled exchangers are ideal for remote locations with limited water supply, and spiral exchangers excel in handling viscous or fouling fluids.

The oil and gas industry relies on heat exchangers to enhance energy efficiency, reduce operational costs, and meet environmental regulations. For instance, shell-and-tube exchangers account for over 60% of global heat exchanger demand in this sector, according to market research. Plate heat exchangers are gaining traction due to their ability to handle high thermal loads with minimal space requirements, making them suitable for offshore platforms. Air-cooled exchangers are widely used in gas processing plants, where water scarcity is a concern, while spiral exchangers are preferred for heavy crude oil applications due to their self-cleaning design. Advanced materials like titanium and stainless steel are increasingly used to combat corrosion and extend equipment lifespan. With the industry’s focus on sustainability, innovations like waste heat recovery systems are driving demand for high-performance heat exchangers. Proper selection and maintenance are crucial to maximizing efficiency and minimizing downtime in these critical operations.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

You can see clear differences between welded block...

More

GPHE heat exchangers are vital in food, HVAC, chem...

More

Plate heat exchangers are becoming more popular be...

More

API 662 defines standards for plate heat exchanger...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe shell and tube heat exchanger we purchased has significantly improved our refinery's efficiency. Highly recommended for the oil and gas industry!

Emily Johnson

Process EngineerThe plate heat exchanger is compact and performs exceptionally well in our gas processing plant. Minor installation challenges, but overall a great product.

Michael Brown

Maintenance SupervisorThe air-cooled heat exchanger has been a game-changer for our offshore platform. Durable and low-maintenance—perfect for harsh environments.

Sarah Davis

Project ManagerThe spiral heat exchanger offers excellent heat transfer for our crude oil applications. Delivery was prompt, and the supplier provided great support.