5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

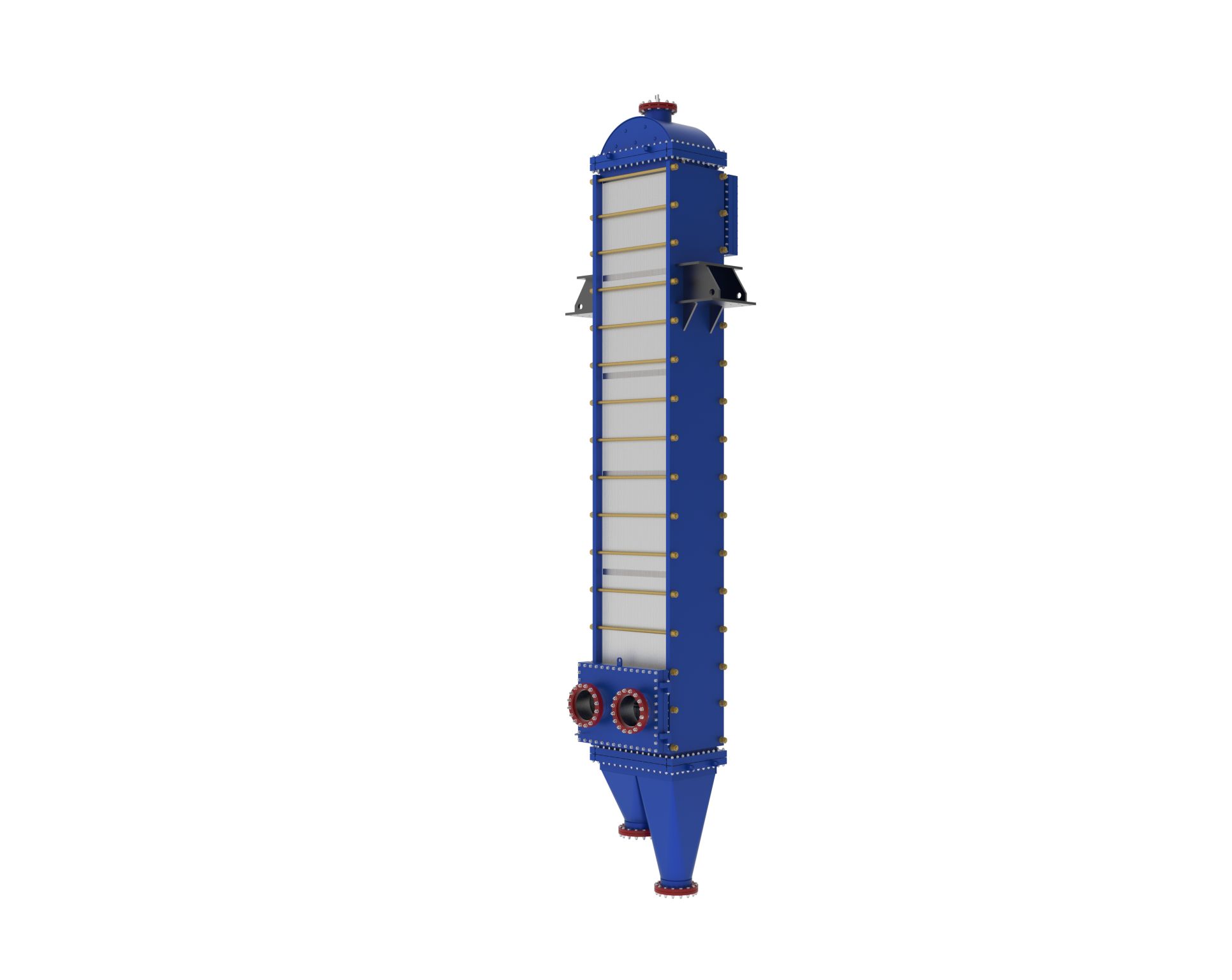

Heat exchangers are critical components in refineries, enabling efficient heat transfer between process fluids. In refineries, the most common types of heat exchangers include **shell-and-tube**, **plate-and-frame**, **air-cooled**, **double-pipe**, and **spiral heat exchangers**. Each type serves specific applications based on factors like temperature, pressure, and fluid compatibility. Shell-and-tube exchangers dominate refinery operations due to their durability and high-pressure handling capabilities, while plate-and-frame exchangers excel in low-viscosity fluid applications. Air-cooled exchangers are ideal for water-scarce environments, and spiral designs handle fouling-prone fluids effectively.

Refineries rely on heat exchangers to optimize energy efficiency and reduce operational costs. According to industry data, shell-and-tube exchangers account for **over 60%** of refinery heat exchanger installations due to their versatility. Plate-and-frame exchangers are gaining traction, with a **15% market share**, driven by their compact design and ease of maintenance. Air-cooled exchangers are preferred in arid regions, reducing water consumption by **up to 90%** compared to water-cooled systems. Spiral heat exchangers, though niche, are valued for handling slurries and corrosive fluids. Leading manufacturers like **Alfa Laval, Kelvion, and API Heat Transfer** provide refinery-grade solutions, ensuring compliance with **ASME and API standards**. Regular maintenance and material selection (e.g., titanium or stainless steel) are crucial to prevent fouling and corrosion, extending equipment lifespan. Investing in the right heat exchanger type can enhance refinery productivity by **20-30%**, making it a strategic priority for plant operators.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

You can see clear differences between welded block...

More

Commercial heat exchangers boost energy efficiency...

More

Their adaptability and efficiency make PHEs a go-t...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Process EngineerThe shell and tube heat exchanger we installed has significantly improved our refinery's efficiency. Highly recommended!

Emily Johnson

Maintenance SupervisorThe plate heat exchanger is compact and easy to maintain, perfect for our refinery's tight spaces. Minor leaks need addressing.

Michael Brown

Operations ManagerThe air-cooled heat exchanger has drastically reduced our water usage in the refinery. Excellent performance and durability.

Sarah Davis

Project EngineerThe spiral heat exchanger handles high-viscosity fluids in our refinery exceptionally well. Installation was straightforward.