How do gaskets prevent leaks in heat exchangers

A gasket in heat exchanger seals surfaces, blocks ...

More

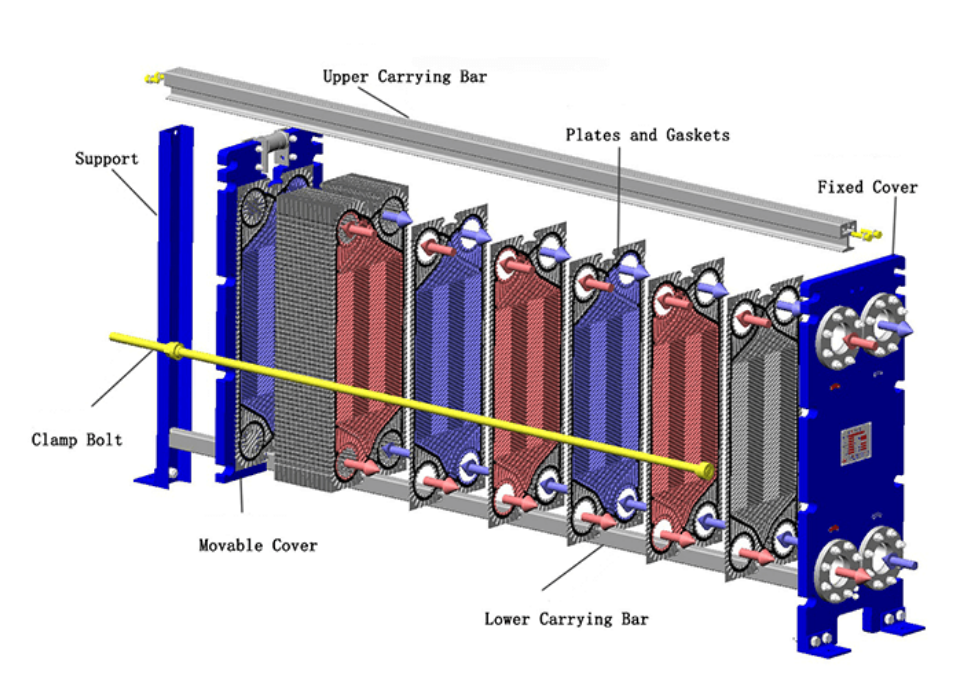

Heat exchangers are critical components in the oil and gas industry, with several types designed to optimize thermal efficiency and operational performance. The most common types include shell and tube, plate and frame, air-cooled, and spiral heat exchangers, each serving distinct functions in refining, processing, and transportation. Shell and tube exchangers dominate the market, accounting for over 60% of industrial applications due to their durability and high-pressure tolerance. Plate and frame exchangers are favored for compact designs and energy efficiency, while air-cooled units reduce water dependency in arid regions. Spiral exchangers excel in handling viscous fluids and fouling-prone processes.

According to industry reports, the global heat exchanger market in oil and gas is projected to reach $22 billion by 2027, driven by rising energy demand and stringent environmental regulations. Shell and tube exchangers remain the preferred choice for upstream operations, whereas plate variants gain traction in midstream and downstream sectors for their modularity. Recent advancements include hybrid designs combining multiple technologies to enhance heat recovery rates by up to 30%. Leading manufacturers like Alfa Laval and Kelvion emphasize corrosion-resistant materials like titanium and nickel alloys to extend equipment lifespan in harsh environments. Case studies from refineries in the Middle East demonstrate how optimized exchanger selection can reduce downtime by 15% and cut operational costs by 20%, making informed choices vital for profitability and sustainability.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

A gasket in heat exchanger seals surfaces, blocks ...

More

You can see clear differences between welded block...

MoreAPI 662 defines standards for plate heat exchanger...

More

Plate heat exchanger gaskets perform 5 key roles: ...

More

Gasketed plate heat exchangers boost industrial ef...

More

Plate heat exchangers cut industrial energy use, l...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe shell and tube heat exchanger we purchased has significantly improved our refinery's efficiency. Highly recommended for oil and gas applications!

Emily Davis

Process EngineerThe plate heat exchanger is compact and performs exceptionally well in our gas processing plant. Minor installation challenges, but overall excellent.

Robert Johnson

Maintenance SupervisorThe air-cooled heat exchanger has been a game-changer for our offshore platform. Durable and low-maintenance—perfect for harsh environments.

Sarah Wilson

Project ManagerThe spiral heat exchanger integrates seamlessly into our crude oil preheating system. Great heat transfer performance with minimal fouling issues.