Understanding api 662 for plate heat exchangers

API 662 defines standards for plate heat exchanger...

More

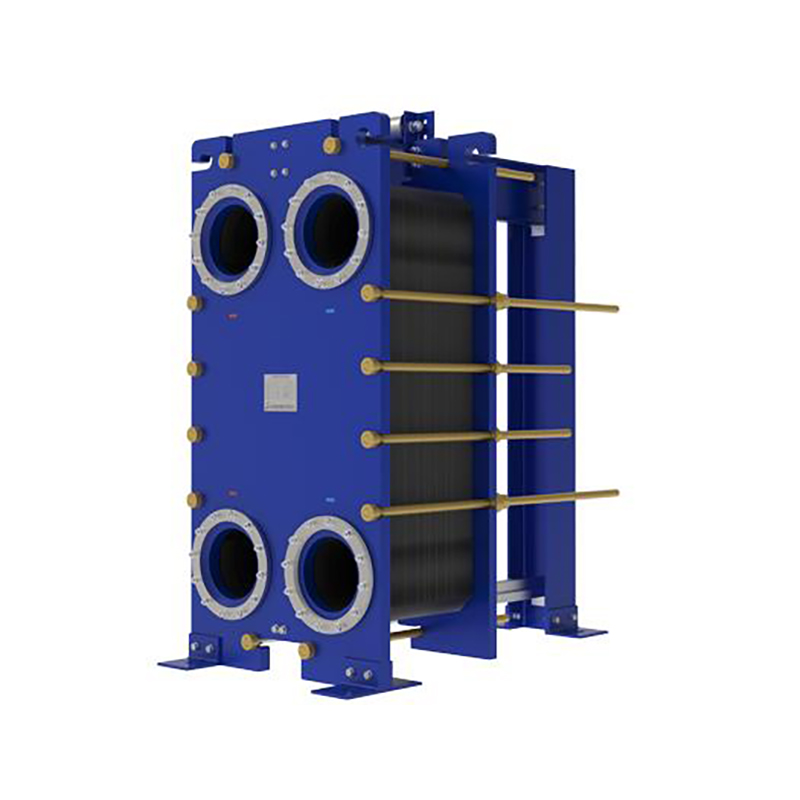

Industrial heat exchangers are essential components in various industries, facilitating efficient heat transfer between fluids. There are several types of industrial heat exchangers, each designed for specific applications and operational conditions. The most common types include shell and tube heat exchangers, plate heat exchangers, air-cooled heat exchangers, and spiral heat exchangers. Understanding these variations helps businesses select the optimal solution for their needs, ensuring energy efficiency and cost-effectiveness.

Shell and tube heat exchangers are widely used in oil refineries, chemical plants, and power generation due to their durability and high-pressure tolerance. According to market research, they account for over 35% of global heat exchanger demand. Plate heat exchangers, known for their compact design and superior thermal efficiency, are prevalent in food processing and HVAC systems. Air-cooled heat exchangers, ideal for water-scarce environments, are favored in petrochemical and gas processing industries. Spiral heat exchangers excel in handling viscous fluids and are often utilized in wastewater treatment and pulp & paper manufacturing. Recent advancements, such as hybrid and microchannel heat exchangers, are gaining traction for their enhanced performance in renewable energy and electronics cooling applications. Industry reports indicate the global heat exchanger market is projected to grow at a CAGR of 5.8% from 2023 to 2030, driven by increasing demand for energy-efficient systems. Choosing the right type ensures operational reliability, reduced maintenance, and compliance with environmental regulations.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

API 662 defines standards for plate heat exchanger...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

You can see clear differences between welded block...

More

Plate heat exchanger gaskets perform 5 key roles: ...

More

Plate heat exchangers are becoming more popular be...

More

Compare top frame plate heat exchanger models for ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe shell and tube heat exchanger we purchased has significantly improved our plant's efficiency. Highly recommended for heavy-duty industrial applications.

Emily Johnson

Process TechnicianThe plate heat exchanger is compact and easy to maintain. Perfect for our food processing needs, though installation required some adjustments.

Michael Brown

HVAC SpecialistThe air-cooled heat exchanger works flawlessly in our HVAC systems. Energy-efficient and durable—exactly what we needed for commercial buildings.

Sarah Lee

Chemical EngineerThe spiral heat exchanger handles corrosive fluids exceptionally well. Minor leaks initially, but the supplier resolved them promptly. Great for chemical plants.