How do gaskets prevent leaks in heat exchangers

A gasket in heat exchanger seals surfaces, blocks ...

More

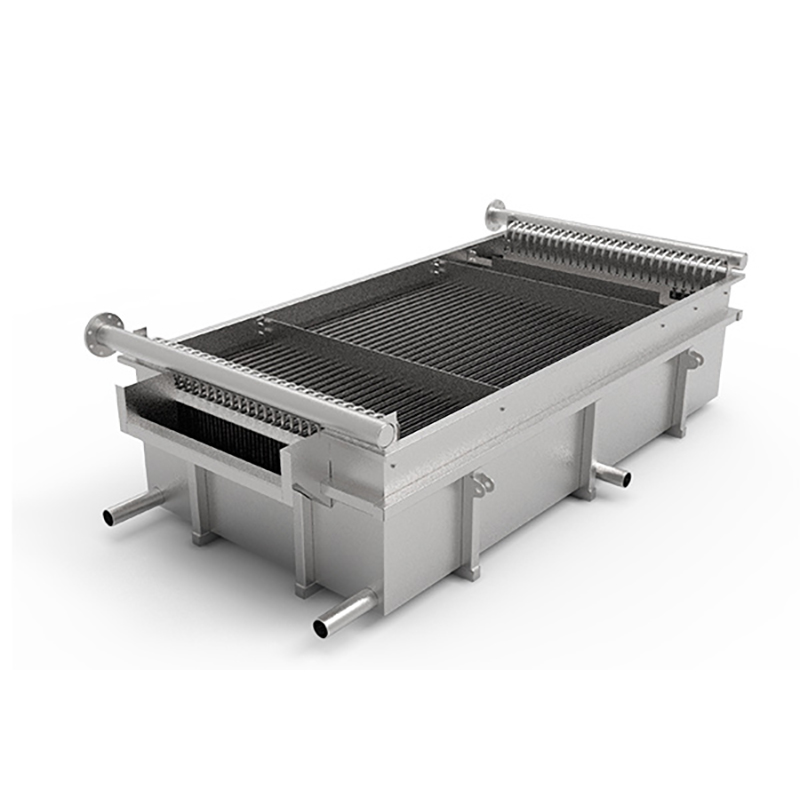

An economiser is a critical heat exchanger device installed in boiler systems to preheat the feed water using waste heat from flue gases before it enters the boiler drum. This process significantly enhances the overall thermal efficiency of the boiler plant by reducing fuel consumption and lowering operational costs. By capturing and repurposing energy that would otherwise be expelled into the atmosphere, economisers directly contribute to substantial energy savings and a reduced carbon footprint. The primary reason for their use is the remarkable improvement in efficiency; industry data and case studies consistently show that installing an economiser can boost boiler efficiency by 5% to 10%. For a large industrial boiler consuming heavy fuel oil, this can translate to annual fuel savings of thousands of dollars, with a typical payback period of less than two years. Furthermore, by lowering the temperature of exhaust flue gases, economisers help reduce the thermal load on downstream pollution control equipment, such as scrubbers or baghouses.

The operational benefits of integrating an economiser into a boiler system are extensive and well-documented through real-world performance metrics. For instance, a comprehensive study by the U.S. Department of Energy on industrial boiler systems demonstrated that for every 40°F (22°C) reduction in flue gas temperature achieved by an economiser, boiler efficiency increases by approximately 1%. In practical terms, this means a system reducing flue gas temperature from 450°F to 250°F can achieve around a 5% efficiency gain. This is not theoretical; data from manufacturers like Cleaver-Brooks and Thermax shows their economiser installations routinely deliver fuel savings of 4% to 8% across various industries, including chemical processing, power generation, and food production. The financial impact is undeniable. A large textile mill reporting annual fuel costs of $1.5 million could save between $60,000 and $120,000 per year. Beyond direct fuel savings, the preheated feed water reduces thermal shock within the boiler, minimizing thermal stress on the pressure vessel and extending the equipment's operational lifespan, which defers capital expenditure on replacements. From an environmental compliance perspective, lower flue gas temperatures also often mean lower NOx emissions, helping plants meet stringent regulatory standards. The combination of hard data on efficiency gains, proven cost savings, enhanced equipment durability, and environmental benefits makes the economiser an indispensable component for any modern, cost-conscious, and sustainable boiler operation.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

A gasket in heat exchanger seals surfaces, blocks ...

More

What the carrying bar does in a PHE—support, align...

More

Plate heat exchangers deliver high thermal efficie...

MoreModern HVAC heater exchangers in 2025 offer superi...

More

Recently, SHPHE received repeat order from custome...

More

Pillow plate technology from Shanghai Heat Transfe...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Reynolds

Chief EngineerAn outstanding economiser that has significantly improved our boiler's efficiency. The installation was straightforward, and we've already seen a noticeable reduction in fuel costs. The build quality is robust and designed to last.

Sarah Chen

Plant ManagerThis economiser unit has been a game-changer for our operation. The heat recovery performance is exceptional, drastically cutting our energy consumption and carbon footprint. A must-have for any facility serious about efficiency and sustainability.

David Rodriguez

Maintenance SupervisorVery impressed with the durability and performance of this economiser. It integrates seamlessly with our existing boiler system. The only minor drawback was a slight delay in delivery, but the product itself is top-notch and well worth the wait.

Emily Watson

Facilities DirectorWe installed this economiser across multiple sites, and the results have been consistently brilliant. The ROI was much faster than anticipated due to the energy savings. The technical support team was also very knowledgeable and helpful during the setup phase.