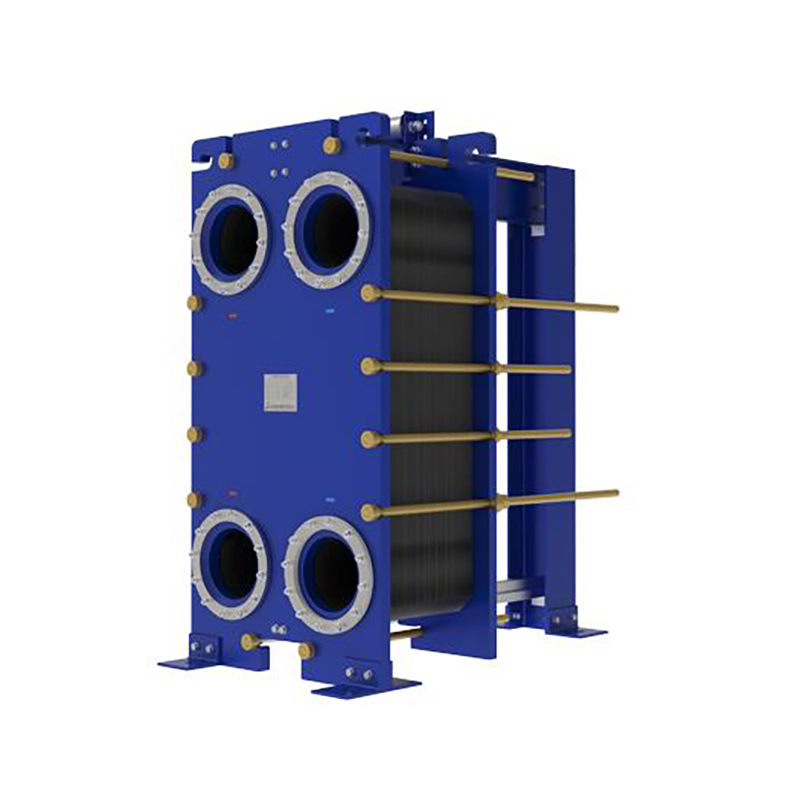

5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

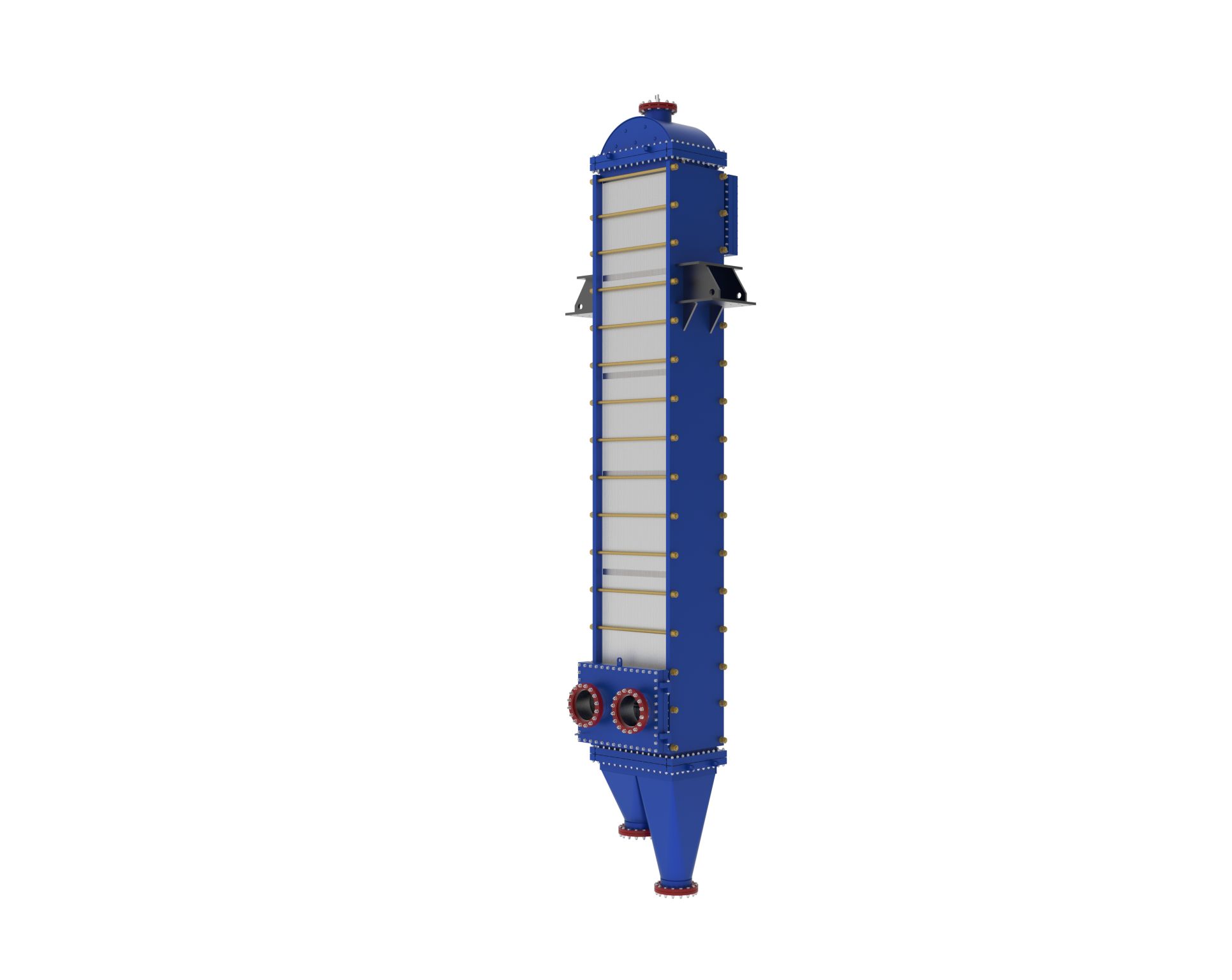

Why use air preheater in thermal power plant? Air preheaters are critical components in thermal power plants, designed to improve boiler efficiency and reduce fuel consumption. By preheating combustion air with waste flue gases, they recover heat that would otherwise be lost, enhancing overall plant performance.

The primary advantage of air preheaters in thermal power plants is their ability to increase thermal efficiency by 5–10%, according to industry studies. This translates to significant cost savings, as every 1% improvement in boiler efficiency can reduce fuel consumption by approximately 0.5%. For a 500 MW coal-fired plant, this could mean annual savings of thousands of tons of coal. Additionally, air preheaters help lower emissions by ensuring more complete combustion, reducing CO2, NOx, and SOx levels.

Modern air preheaters, such as rotary regenerative or tubular types, are engineered for durability and minimal maintenance. Data from power plants using advanced preheater systems shows a reduction in unplanned downtime by up to 15%, further optimizing operational reliability. With global energy demands rising, investing in high-efficiency air preheaters is a proven strategy for power plants to meet environmental regulations while maximizing profitability. Industry leaders like GE and Howden report that optimized air preheater systems can achieve payback periods as short as 2–3 years, making them a smart long-term investment for sustainable energy production.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

You can see clear differences between welded block...

More

Maximize energy efficiency and cut costs by select...

More

Commercial heat exchangers boost energy efficiency...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe air preheater significantly improved our plant's efficiency by recovering waste heat. Installation was smooth, and the build quality is excellent.

Emily Johnson

Plant OperatorThis air preheater has reduced fuel consumption and emissions in our facility. Minor maintenance issues, but overall a great investment.

Robert Brown

Maintenance SupervisorDurable and reliable air preheater with minimal downtime. The corrosion-resistant design is perfect for long-term use in harsh conditions.

Sarah Davis

Process EngineerEfficient heat recovery and compact design saved space in our plant. Customer support was responsive during commissioning.