How do gaskets prevent leaks in heat exchangers

A gasket in heat exchanger seals surfaces, blocks ...

More

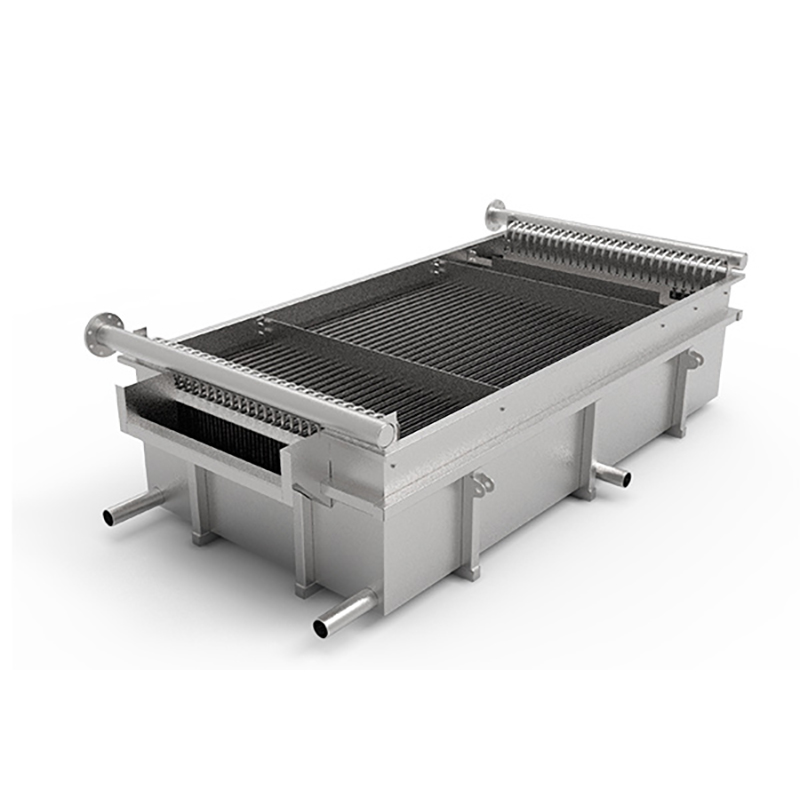

Economisers are critical components in power plants, designed to improve energy efficiency by recovering waste heat from flue gases. By preheating the feedwater before it enters the boiler, economisers reduce fuel consumption and lower operational costs. Studies show that integrating an economiser can improve boiler efficiency by 5-10%, significantly cutting CO2 emissions. For example, a 500 MW coal-fired power plant can save up to 20,000 tons of coal annually, translating to millions in cost savings. With rising fuel prices and stricter environmental regulations, economisers are no longer optional but essential for sustainable power generation.

Modern economisers are engineered for durability and high performance, capable of withstanding extreme temperatures and corrosive flue gases. Advanced materials like stainless steel and ceramic coatings extend their lifespan, reducing maintenance costs. According to industry reports, power plants using economisers see a payback period of 2-3 years due to energy savings. Additionally, economisers help plants comply with emissions standards like the EPA’s Clean Air Act, avoiding hefty fines. Whether for coal, gas, or biomass plants, economisers deliver measurable ROI while supporting global decarbonization goals. Investing in a high-quality economiser is a smart move for any power plant aiming to optimize efficiency and reduce its environmental footprint.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

A gasket in heat exchanger seals surfaces, blocks ...

More

What the carrying bar does in a PHE—support, align...

More

Plate heat exchangers deliver high thermal efficie...

MoreModern HVAC heater exchangers in 2025 offer superi...

More

Recently, SHPHE received repeat order from custome...

More

Pillow plate technology from Shanghai Heat Transfe...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe economiser installed in our power plant has significantly improved fuel efficiency. Highly recommended!

Emily Johnson

Plant ManagerGreat product! The economiser reduced our operational costs and increased overall plant performance.

Michael Brown

Maintenance SupervisorReliable and durable economiser. Easy to maintain and has a long service life. Excellent investment for any power plant.

Sarah Davis

Environmental EngineerThe economiser helps reduce emissions while improving efficiency. A must-have for sustainable power plants.