How Plate Air Preheaters Improve Industrial Efficiency

Plate air preheaters transform industrial processe...

More

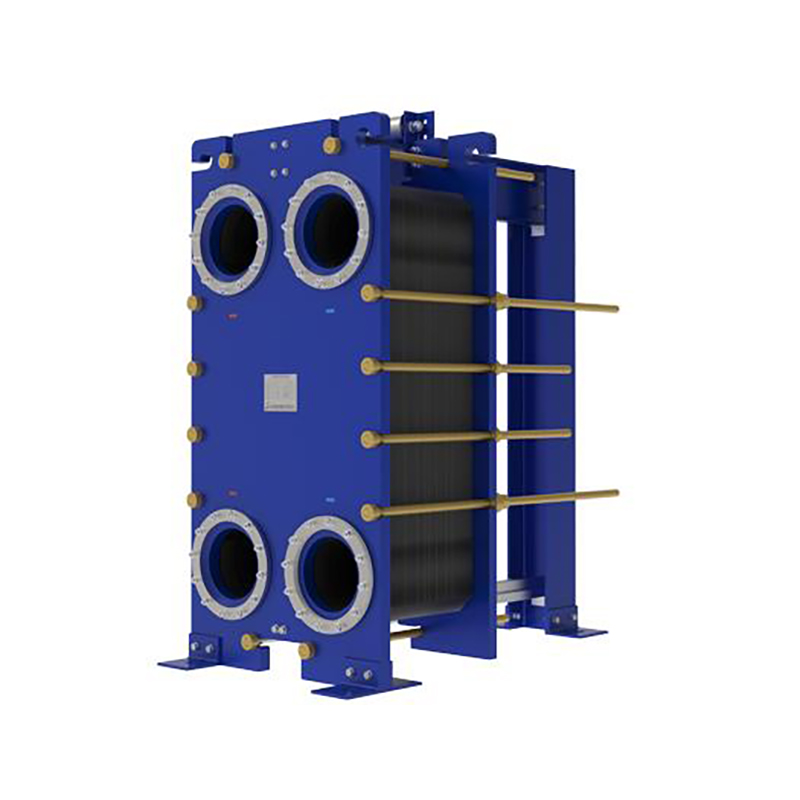

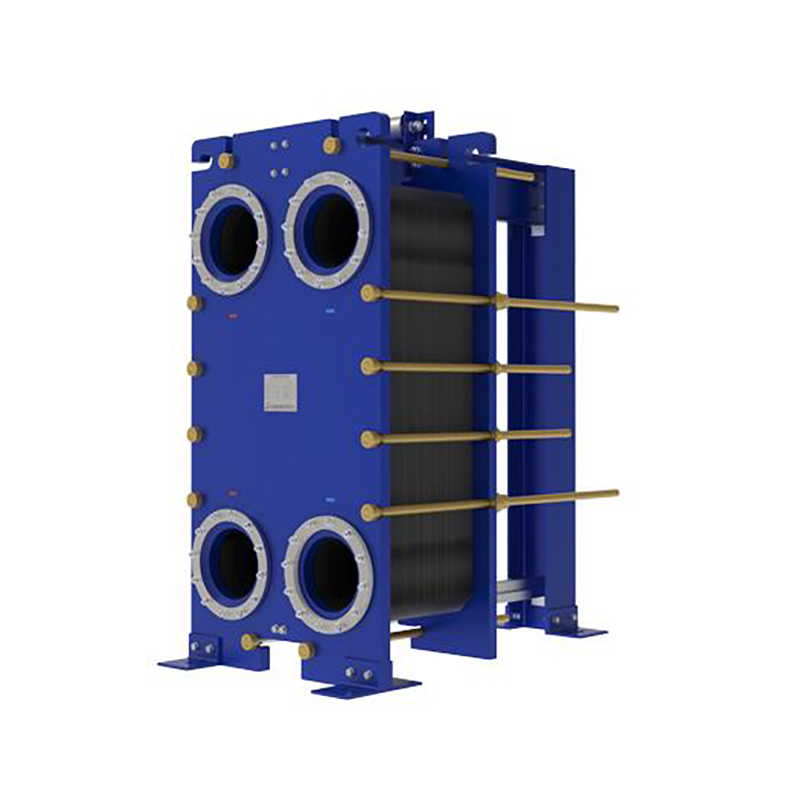

An economiser in a boiler is a critical component designed to improve energy efficiency by recovering waste heat from flue gases. By preheating the feedwater before it enters the boiler, economisers significantly reduce fuel consumption and operational costs. Studies show that installing an economiser can improve boiler efficiency by 5-15%, depending on the system’s design and operating conditions. For industries relying on steam generation, this translates to substantial savings—up to $50,000 annually for a mid-sized plant. Additionally, economisers help reduce carbon emissions, aligning with global sustainability goals and regulatory requirements.

Modern economisers are engineered for durability and compatibility with various boiler types, including fire-tube, water-tube, and biomass boilers. According to industry data, facilities using economisers report a payback period of 1-3 years due to lowered fuel expenses. For example, a 2019 case study by the U.S. Department of Energy highlighted a textile plant that achieved a 12% efficiency gain after retrofitting its boiler with an economiser, saving over $30,000 per year. Beyond cost savings, economisers extend boiler lifespan by reducing thermal stress and minimizing scale buildup. With rising energy prices, investing in an economiser is a proven strategy to enhance operational efficiency while supporting environmental stewardship.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

.jpg)

Plate air preheaters transform industrial processe...

More

Factories in 2025 rely on advanced gasketed heat e...

More

Advanced heat exchanger solutions like the TP Weld...

More

Shanghai Plate Heat Exchanger stands at the forefr...

More

Industrial users gain significant value from a gas...

More

Choosing the best gasketed plate heat exchanger st...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

David Chen

Chief EngineerThe installation of this economiser has dramatically improved our boiler's efficiency. We've seen a consistent 8% reduction in fuel consumption, which translates to significant cost savings and a lower carbon footprint. A top-quality, robust product.

Sarah Wilkinson

Plant ManagerOutstanding performance and build quality. This economiser integrated seamlessly with our existing boiler system. The heat recovery has been exceptional, allowing us to meet our plant's steam demand more efficiently. Highly recommended for any industrial application.

Michael Rodriguez

Facilities DirectorA very effective solution for waste heat recovery. Our hospital's energy bills have noticeably decreased since the retrofit. The only reason it's not a 5 is due to a slightly longer than expected delivery time, but the product itself is excellent.

James O'Connell

Maintenance SupervisorThis economiser is built to last. The corrosion-resistant materials are perfect for our chemical plant's demanding environment. It's been running flawlessly for months with minimal maintenance, making our entire steam generation process much more economical.