5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

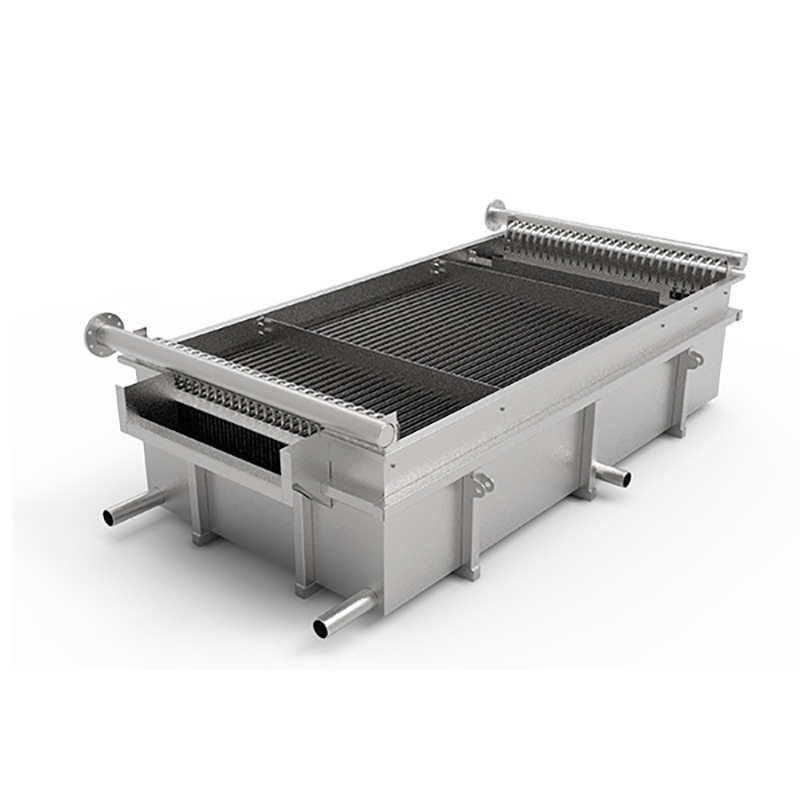

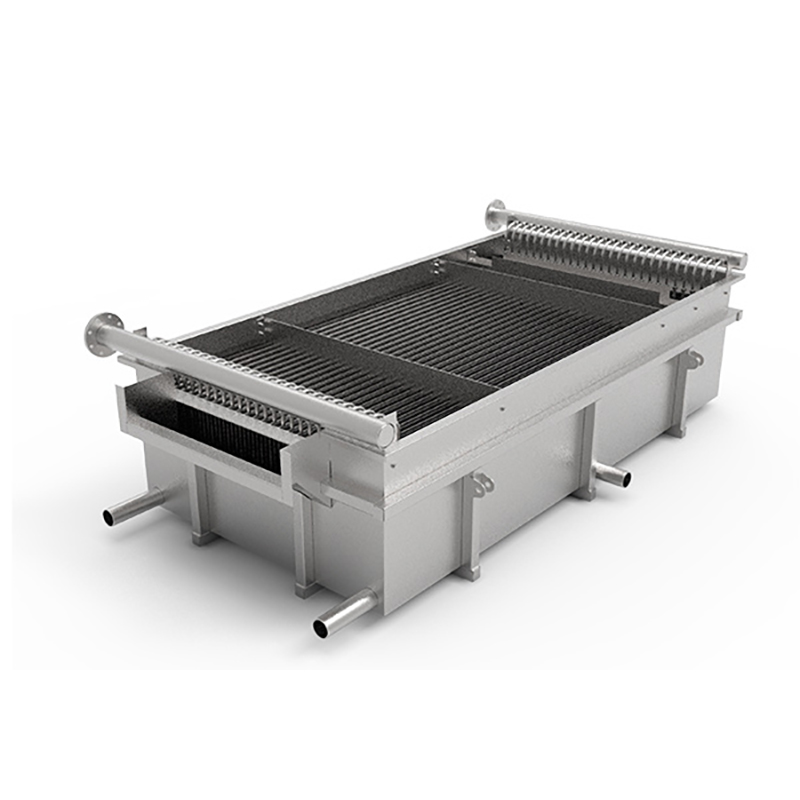

Pillow plates, also known as embossed or dimpled plates, are specialized metal sheets with a unique pattern of welded dimples or pockets. These plates are created by welding two thin metal sheets together at specific points, forming a cushion-like structure that enhances heat transfer efficiency. Commonly made from stainless steel, carbon steel, or aluminum, pillow plates are widely used in industries such as chemical processing, food and beverage, pharmaceuticals, and HVAC systems. Their design allows for optimal thermal conductivity while maintaining structural strength, making them ideal for applications like heat exchangers, cooling panels, and evaporators. The embossed surface increases the effective heat transfer area, improving performance compared to flat plates.

Pillow plates offer exceptional versatility due to their customizable dimensions, materials, and dimple patterns. They can be tailored to meet specific thermal or mechanical requirements, ensuring compatibility with diverse industrial processes. The welded dimples create internal channels that facilitate efficient fluid flow or gas distribution, further enhancing heat exchange capabilities. Additionally, their lightweight yet durable construction reduces material costs without compromising performance. Industries favor pillow plates for their corrosion resistance, ease of cleaning, and ability to handle high-pressure environments. From brewery tanks to solar thermal systems, these plates are a proven solution for optimizing energy efficiency and reducing operational costs.

Pillow plates are the preferred choice for industries seeking high-performance heat transfer solutions due to their unmatched efficiency, durability, and cost-effectiveness. Studies and real-world applications demonstrate that pillow plates can achieve up to 30% better thermal performance compared to traditional flat plates, significantly reducing energy consumption. Their robust welded structure ensures longevity, even in corrosive or high-temperature environments, minimizing maintenance and replacement costs. The enlarged surface area from the dimpled design maximizes heat exchange, making them ideal for applications where space or weight constraints exist, such as in aerospace or compact industrial equipment.

Data from market research indicates a growing adoption of pillow plates in renewable energy systems, particularly in solar thermal and waste heat recovery projects, where their efficiency translates into higher ROI. Manufacturers also highlight their eco-friendly benefits, as the reduced material usage and energy savings contribute to sustainability goals. Furthermore, pillow plates are compatible with automated production lines, enabling scalable and consistent quality for large-scale projects. With certifications like ISO 9001 and ASME compliance, these plates meet stringent industry standards, ensuring reliability. Whether for chemical reactors, refrigeration units, or power plants, pillow plates deliver superior performance, making them a smart investment for modern industrial applications.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

API 662 defines standards for plate heat exchanger...

More

Compare top frame plate heat exchanger models for ...

More

Pillow plate technology from Shanghai Heat Transfe...

More

You can see clear differences between welded block...

More

Modern pillow plate heat exchangers achieve higher...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Emily Johnson

Mechanical EngineerThe pillow plate design is excellent for heat transfer applications. Highly recommended for industrial use!

Michael Chen

Process EngineerGreat product for our heat exchanger systems. Easy to install and efficient performance.

Sarah Williams

HVAC TechnicianPillow plates have significantly improved our system's thermal efficiency. Very durable and well-made.

David Brown

Project ManagerReliable and cost-effective solution for our heat transfer needs. Customer service was also very responsive.