A complete list of top industries using GPHE heat exchangers in 2026

GPHE heat exchangers are vital in food, HVAC, chem...

More

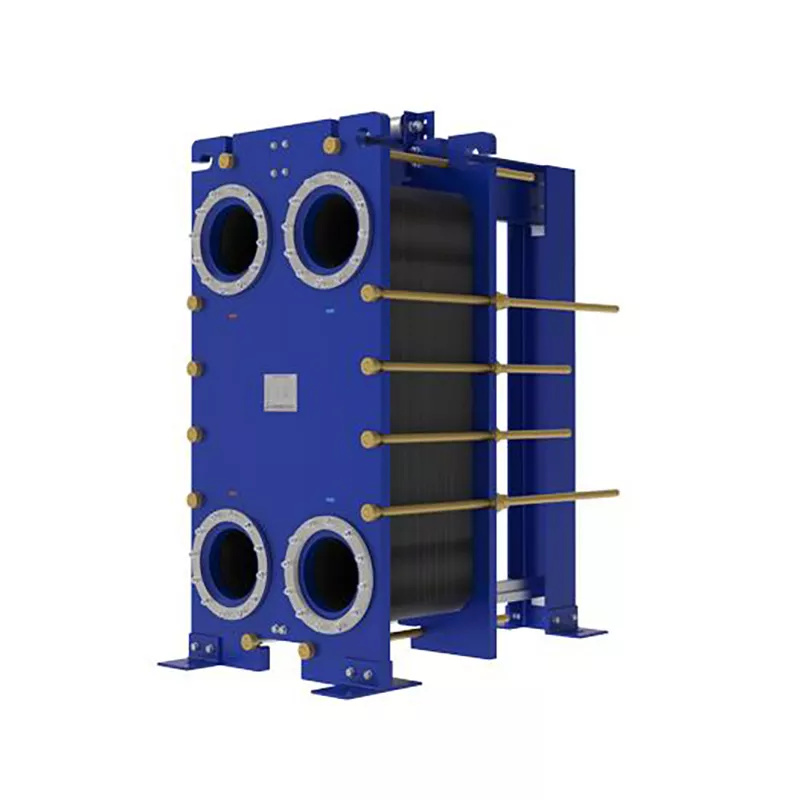

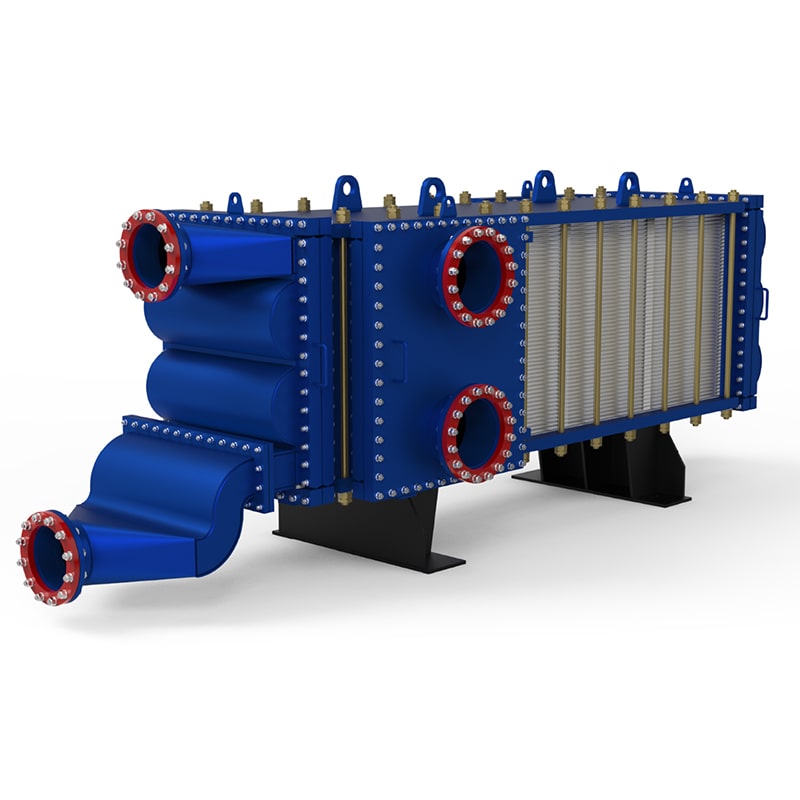

A lube oil cooler is a heat exchanger designed to regulate the temperature of lubricating oil in industrial machinery, engines, and hydraulic systems. By dissipating excess heat, it ensures optimal viscosity and performance of the oil, preventing equipment overheating and premature wear. These coolers are critical in industries such as power generation, marine, automotive, and manufacturing, where consistent lubrication is vital for operational efficiency. Available in various designs—including shell-and-tube, plate-type, and air-cooled models—lube oil coolers are engineered to meet specific thermal management needs.

Lube oil coolers work by transferring heat from the oil to a cooling medium, such as water or air, through a series of tubes or plates. This process maintains the oil at an ideal temperature range, typically between 40°C and 60°C, depending on the application. Modern coolers incorporate advanced materials like stainless steel or aluminum for durability and corrosion resistance. According to industry reports, properly maintained lube oil coolers can extend machinery lifespan by up to 30% and reduce energy consumption by 15–20% by minimizing friction. They are also compliant with international standards like ISO 9001 and API 614, ensuring reliability in demanding environments.

Choosing a lube oil cooler enhances equipment reliability, reduces maintenance costs, and improves energy efficiency. Industries relying on heavy machinery, such as oil refineries or marine vessels, report up to 25% fewer breakdowns when using high-quality coolers. These systems are designed to handle extreme pressures (up to 300 psi) and temperatures (up to 200°C), making them indispensable for critical operations. Additionally, coolers with modular designs allow for easy installation and scalability, adapting to evolving industrial needs.

Data from market research indicates that lube oil coolers can lower operational costs by 10–15% annually by optimizing oil performance and reducing downtime. For example, a case study in the power sector showed a 20% increase in turbine efficiency after installing a plate-type cooler. Leading manufacturers like Alfa Laval and SWEP offer customizable solutions with warranties exceeding 5 years, backed by global service networks. Environmental benefits include reduced oil degradation and lower carbon footprints, aligning with sustainability goals. With advancements like predictive maintenance sensors, modern coolers also integrate seamlessly into Industry 4.0 frameworks, providing real-time performance analytics.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

GPHE heat exchangers are vital in food, HVAC, chem...

MoreWelded PHE for high pressure from top manufacturer...

More

API 662 defines standards for plate heat exchanger...

More

The primary heat exchangers industries served are ...

More

The best manufacturers of stainless heat exchanger...

More

Recently, an offshore oil and gas platform equippe...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe lube oil cooler works perfectly in our heavy machinery. It significantly reduced the operating temperature and improved efficiency.

Emily Johnson

Maintenance SupervisorGreat product! The lube oil cooler is durable and easy to install. It has helped us maintain optimal performance in our equipment.

Michael Brown

Plant ManagerHighly recommend this lube oil cooler. It has been a game-changer for our cooling system, ensuring smooth operations with minimal downtime.

Sarah Davis

HVAC TechnicianThe lube oil cooler is efficient and reliable. It has helped us maintain consistent performance in our cooling systems.