Leakage free air preheater picks that stop waste now

Leakage free air preheater solutions from top bran...

More

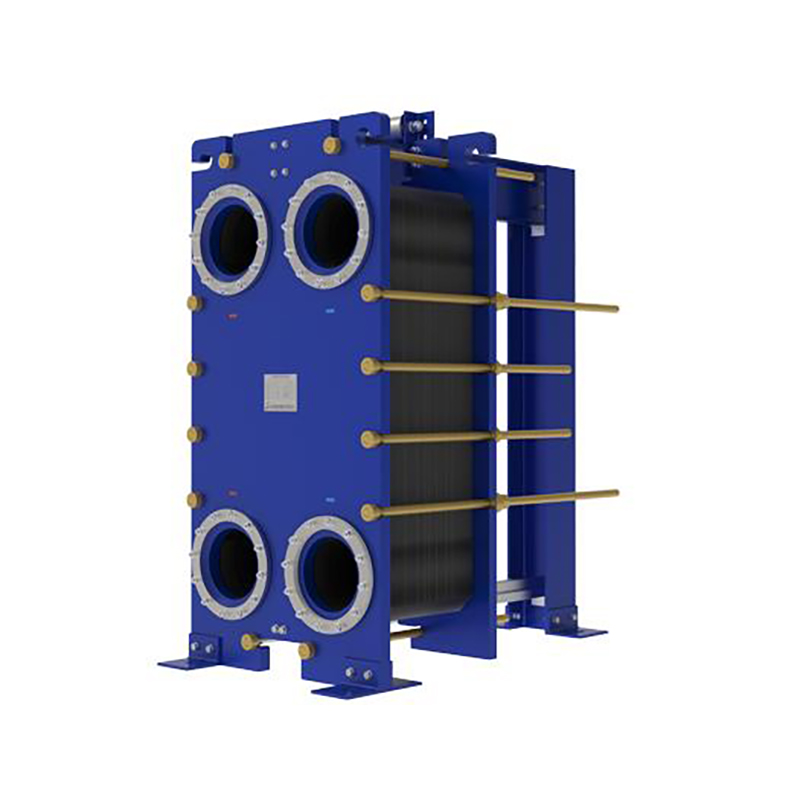

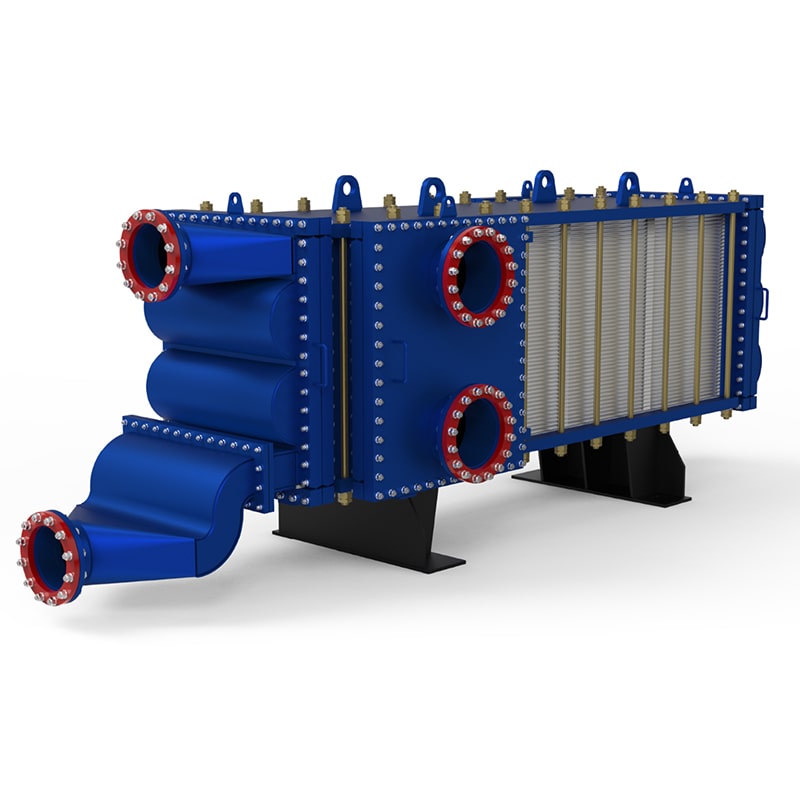

An air preheater (APH) is a critical heat recovery device used in industrial boilers, power plants, and process heating systems to improve thermal efficiency. It works by transferring waste heat from flue gases to incoming combustion air, reducing fuel consumption and emissions. Common types include recuperative (plate or tube-based) and regenerative (rotating or stationary) designs. Modern APHs achieve efficiency gains of 10-30%, with advanced models like Ljungström® rotary preheaters reaching 90%+ heat recovery. Industries leveraging APHs report 5-15% fuel savings annually, with payback periods under 2 years in high-usage scenarios.

Selecting an air preheater delivers measurable ROI through energy optimization and regulatory compliance. Data from the U.S. DOE shows industrial facilities using APHs reduce CO₂ emissions by 8-12% while cutting fuel costs by $50,000-$200,000 yearly per unit. Key advantages include: 1) Extended equipment life by lowering thermal stress on boilers (proven 20% lifespan increase in NREL studies), 2) Compliance with EPA emissions standards through more complete combustion, and 3) Operational flexibility with modular designs handling 200-1,500°C exhaust gases. Leading manufacturers like Howden and GE report 98% availability rates for maintenance-optimized APH systems.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Leakage free air preheater solutions from top bran...

More

What is a heat exchanger? It's a device that trans...

More

User reviews show the american standard heat excha...

More

A standard exchange heat exchanger boosts industri...

More

Industries in 2025 achieve higher efficiency by ad...

More

Understanding welded heat exchanger's unique const...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe air preheater works flawlessly and has significantly improved our plant's efficiency. Highly recommended!

Emily Johnson

Process EngineerGreat product with durable construction. Installation was straightforward, and it performs as expected.

Michael Brown

Maintenance SupervisorThis air preheater has reduced our energy costs and maintenance downtime. Excellent investment for any industrial facility.

Sarah Davis

HVAC SpecialistReliable and efficient. The air preheater integrates well with our existing systems and delivers consistent performance.