5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

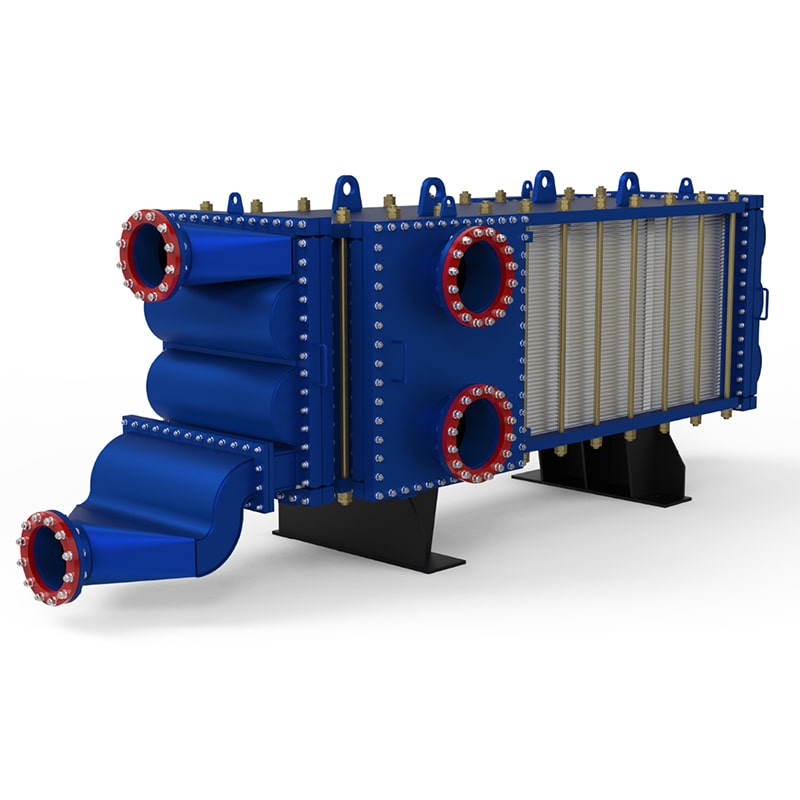

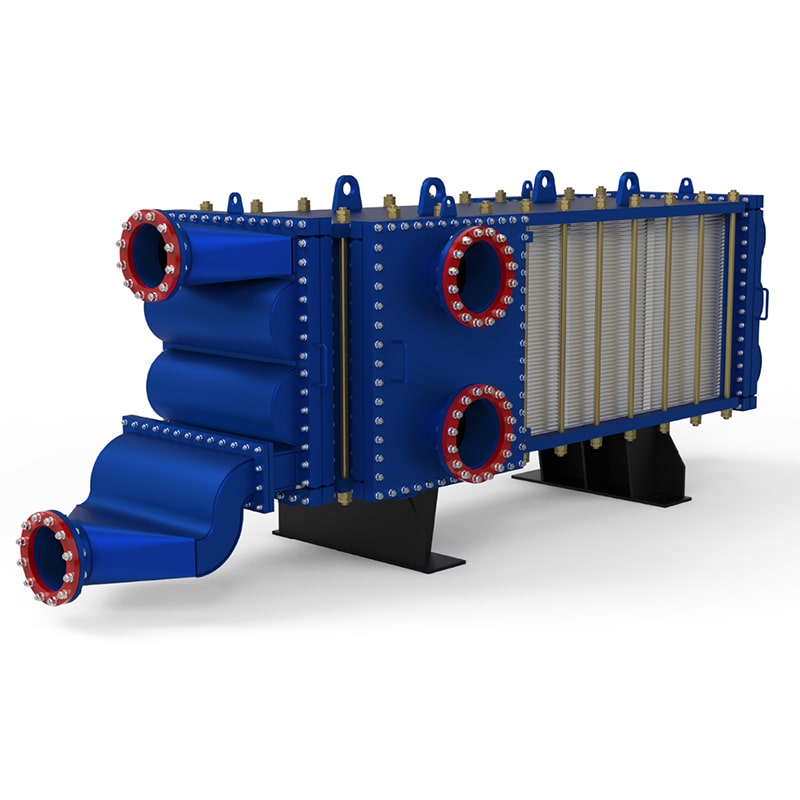

The heat exchange refers to the process of transferring thermal energy between two or more fluids or systems at different temperatures, widely used in HVAC, power plants, refrigeration, and industrial applications. Heat exchangers are critical components that enhance energy efficiency, reduce operational costs, and support sustainable practices by optimizing thermal management. Common types include shell-and-tube, plate, and air-cooled exchangers, each designed for specific performance requirements.

Heat exchangers play a vital role in modern industries by ensuring optimal temperature control, improving system longevity, and minimizing energy waste. For example, in HVAC systems, they recover heat from exhaust air to preheat incoming fresh air, cutting energy consumption by up to 40%. In power plants, condensers and boilers rely on heat exchangers to maximize efficiency, with some systems achieving over 90% thermal transfer rates. Data from the U.S. Department of Energy highlights that industrial heat recovery can save up to 20% of total energy costs annually. Additionally, advancements in materials like titanium and graphene have enhanced durability and corrosion resistance, making heat exchangers ideal for harsh environments such as chemical processing and marine applications.

Selecting the right heat exchange solution ensures long-term reliability, energy efficiency, and compliance with environmental regulations. Industries prioritize heat exchangers for their ability to handle high-pressure and high-temperature conditions while maintaining consistent performance. For instance, Alfa Laval’s plate heat exchangers demonstrate 50% higher efficiency than traditional models, reducing both footprint and operational expenses. According to a Grand View Research report, the global heat exchanger market is projected to reach $26.5 billion by 2028, driven by demand for energy-efficient systems in oil & gas, food processing, and renewable energy sectors. Moreover, modular designs allow for easy scalability, catering to small-scale operations and large industrial plants alike.

Investing in advanced heat exchange technology translates to significant financial and environmental benefits. Case studies show that companies using optimized heat recovery systems reduce carbon emissions by 15-30%, aligning with global sustainability goals like the Paris Agreement. For example, a refinery in Germany reported annual savings of €2 million after upgrading to high-efficiency plate exchangers. Furthermore, government incentives, such as tax credits for energy-efficient equipment, further lower adoption costs. With minimal maintenance requirements and lifespans exceeding 20 years, heat exchangers deliver unmatched ROI, making them indispensable for forward-thinking industries aiming to cut costs and boost productivity.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

You can see clear differences between welded block...

More

A heat exchanger plate is vital for industrial eff...

More

Shanghai Plate Heat Exchanger leads innovation wit...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe heat exchange system is incredibly efficient and has significantly improved our plant's performance. Highly recommended!

Emily Johnson

HVAC TechnicianGreat product! The heat exchange unit works flawlessly and has reduced energy costs for our clients. A few minor improvements could make it perfect.

Michael Brown

Plant ManagerOutstanding heat exchange solution. It has exceeded our expectations in terms of durability and efficiency. Will definitely purchase again.

Sarah Davis

Chemical EngineerThe heat exchange system is reliable and easy to maintain. It has been a great addition to our laboratory setup. Very satisfied!