Understanding api 662 for plate heat exchangers

API 662 defines standards for plate heat exchanger...

More

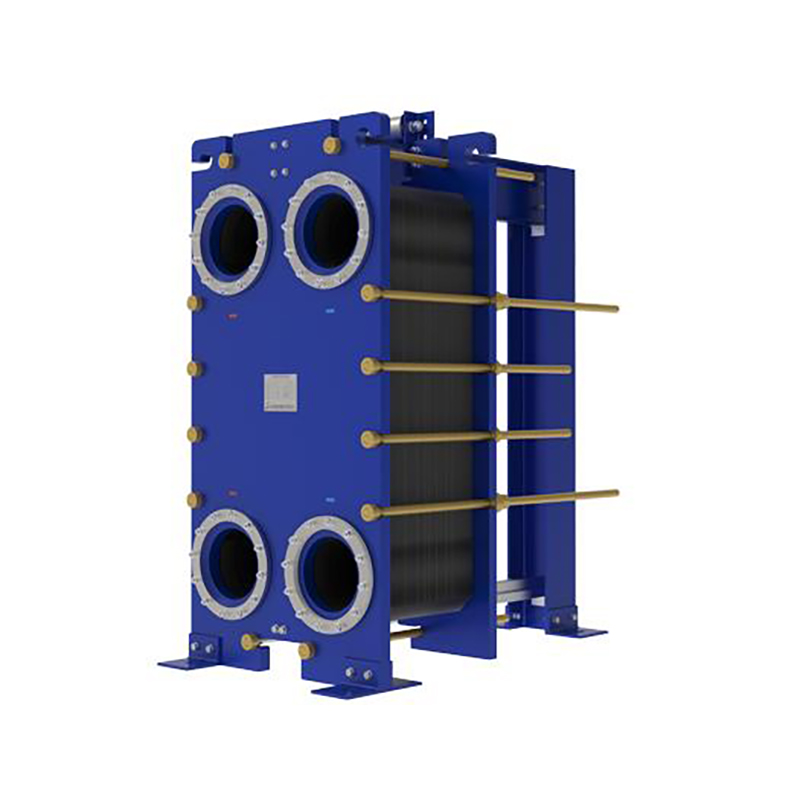

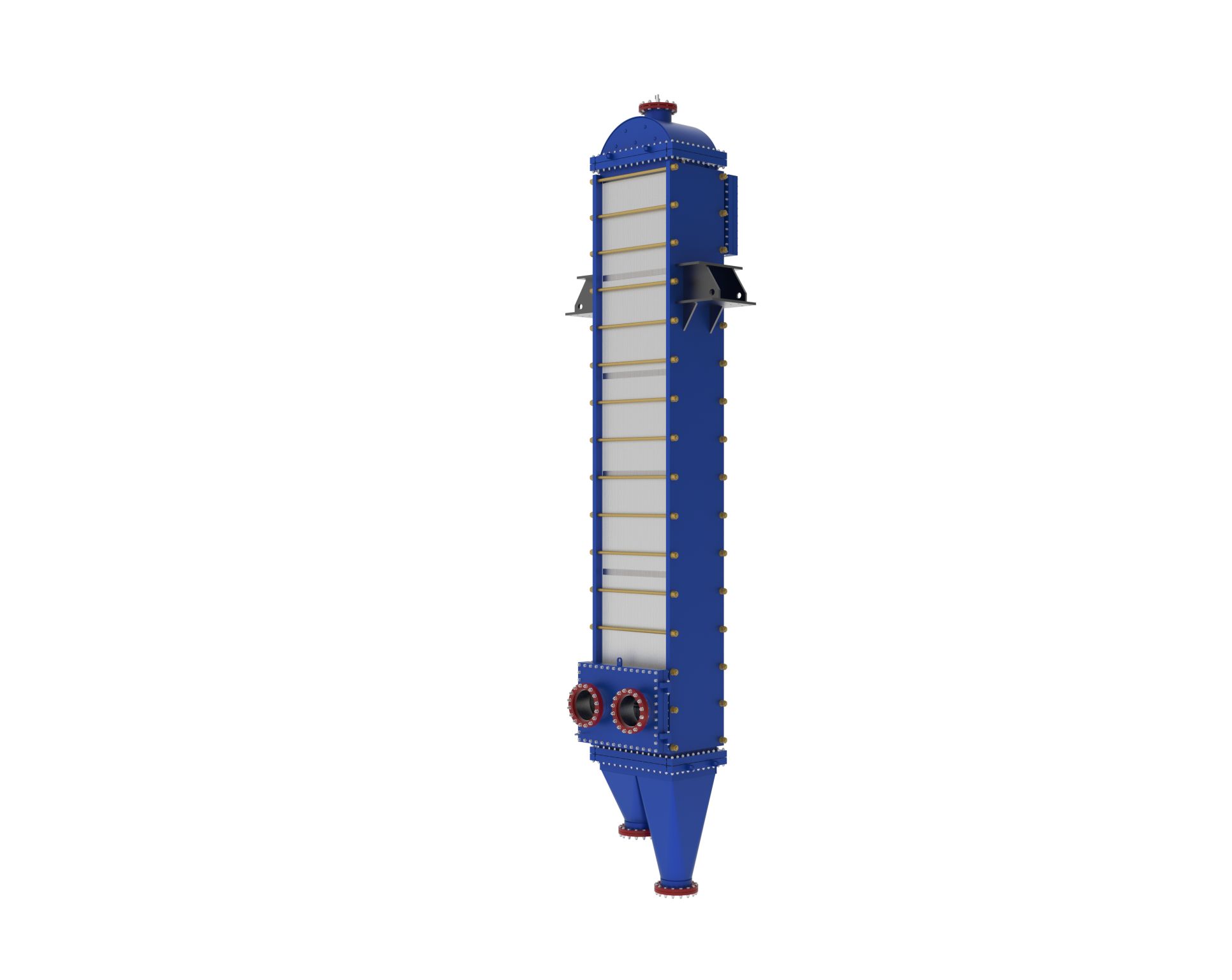

A dryer heat exchanger is a specialized device designed to recover and reuse waste heat generated during industrial or commercial drying processes. It captures thermal energy from exhaust air or gases and transfers it to incoming fresh air, significantly improving energy efficiency. These systems are commonly used in industries like food processing, textiles, paper manufacturing, and chemical production, where large-scale drying operations consume substantial energy. Modern dryer heat exchangers utilize advanced materials like stainless steel or corrosion-resistant alloys to withstand high temperatures and harsh environments. They come in various configurations, including plate, tubular, and rotary designs, each optimized for specific applications. By recycling heat that would otherwise be lost, these systems can reduce energy consumption by 20-40%, making them a critical component for sustainable operations.

Investing in a dryer heat exchanger delivers measurable economic and environmental benefits. Industry data shows these systems typically pay for themselves within 1-3 years through energy savings alone. For example, a 2023 case study in the textile sector demonstrated a 32% reduction in natural gas consumption after installing a plate heat exchanger. Beyond cost savings, heat exchangers help facilities meet increasingly stringent emissions regulations by lowering their carbon footprint. They also improve process consistency by preheating incoming air, which enhances product quality in temperature-sensitive applications like pharmaceutical or food drying. Modern designs feature easy maintenance access and automated cleaning systems, minimizing downtime. With rising energy costs and sustainability mandates, dryer heat exchangers have become essential equipment for any operation seeking to optimize its drying processes while demonstrating environmental responsibility.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

API 662 defines standards for plate heat exchanger...

More

Plate heat exchangers deliver high thermal efficie...

More

Plate heat exchangers boost industrial energy effi...

More

Maximize energy efficiency and cut costs by select...

More

Commercial heat exchangers boost energy efficiency...

More

Plate heat exchanger solutions boost efficiency, r...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe dryer heat exchanger is incredibly efficient and has significantly reduced our energy costs. Highly recommended for industrial applications!

Emily Johnson

Facility ManagerThis heat exchanger works great in our laundry facility. Easy to install and maintain, though a bit pricey upfront.

Robert Brown

HVAC TechnicianOutstanding performance and durability. Perfect for commercial drying systems—no issues after months of heavy use.

Sarah Davis

Plant OperatorReliable and robust heat exchanger. Minor improvements in airflow design could make it perfect, but still a top choice.