Leakage free air preheater picks that stop waste now

Leakage free air preheater solutions from top bran...

More

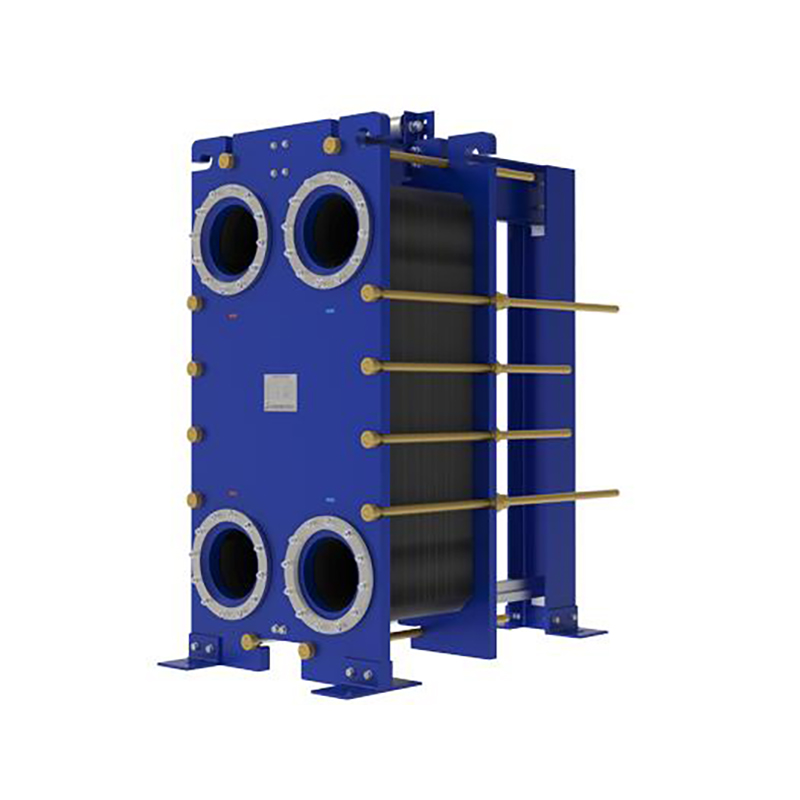

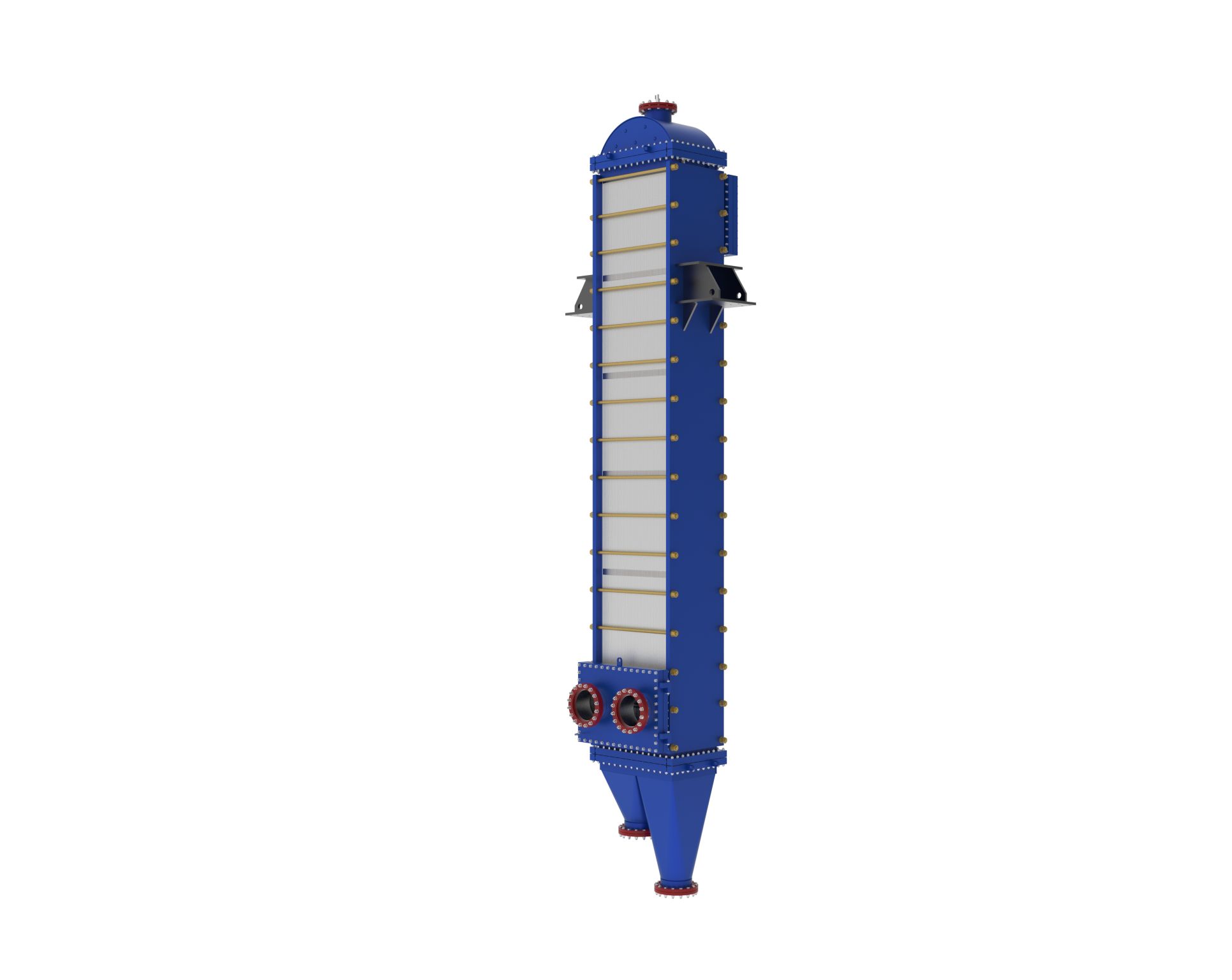

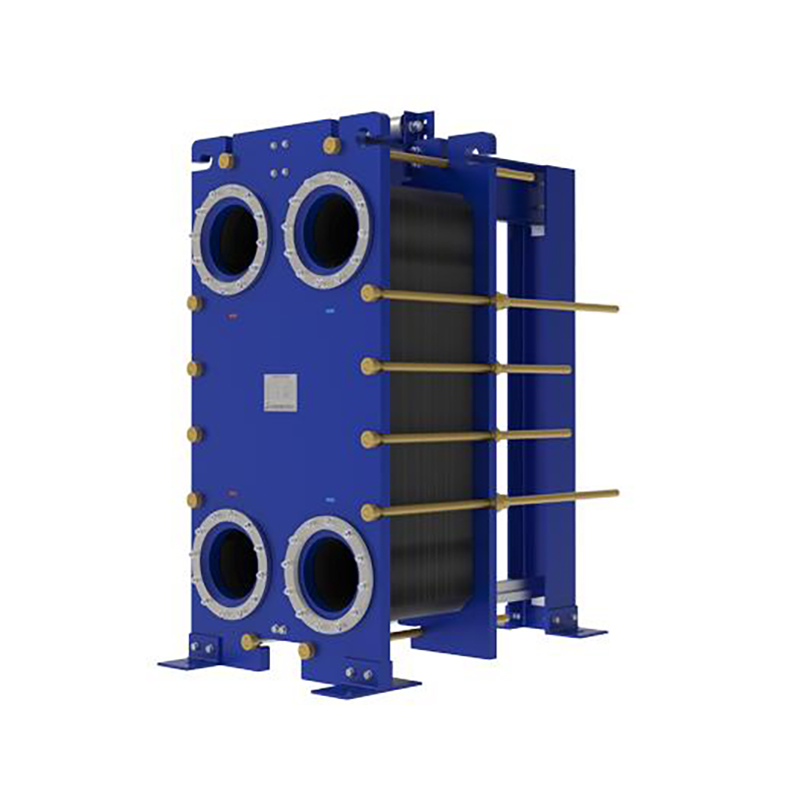

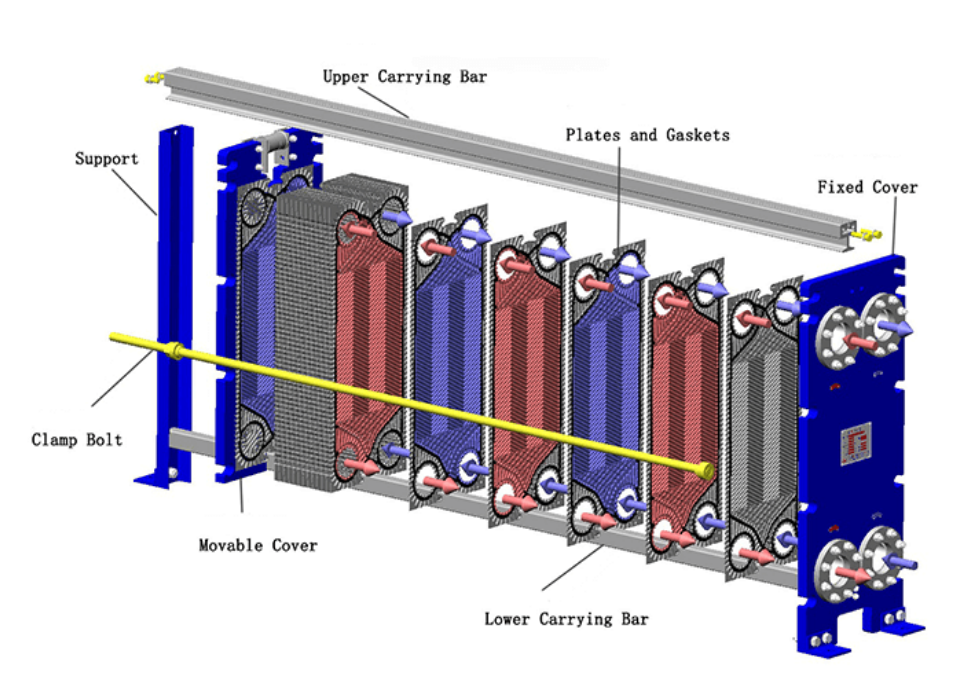

An air preheater boiler is a critical component in industrial and power plant boiler systems designed to recover waste heat from flue gases and transfer it to combustion air before it enters the furnace. This process significantly improves thermal efficiency by preheating incoming air, reducing fuel consumption, and lowering emissions. Air preheaters are commonly used in coal-fired, gas-fired, and biomass boiler systems, where they enhance combustion efficiency and overall plant performance. These devices come in various types, including regenerative and recuperative air preheaters, each tailored to specific operational requirements. By integrating an air preheater, industries can achieve substantial energy savings and comply with stringent environmental regulations.

The primary function of an air preheater boiler is to capture residual heat from exhaust gases, which would otherwise be wasted, and use it to raise the temperature of combustion air. This preheated air ensures more complete fuel combustion, leading to higher boiler efficiency and reduced operational costs. Modern air preheaters are engineered to handle high temperatures and corrosive flue gases, making them durable and reliable for long-term use. Industries such as power generation, chemical processing, and manufacturing heavily rely on these systems to optimize energy use and minimize carbon footprints. With advancements in materials and design, air preheaters now offer better heat transfer rates and lower maintenance requirements, making them indispensable for sustainable industrial operations.

Choosing an air preheater boiler delivers measurable benefits, including enhanced energy efficiency, cost savings, and environmental compliance. Studies show that integrating an air preheater can improve boiler efficiency by 5–10%, directly reducing fuel consumption and operational expenses. For example, power plants using air preheaters report annual fuel savings of up to 15%, translating to significant financial returns. Additionally, preheating combustion air lowers nitrogen oxide (NOx) emissions, helping industries meet regulatory standards and avoid penalties. The long-term ROI of air preheaters makes them a smart investment for any facility prioritizing sustainability and cost-effectiveness.

Air preheater boilers also offer operational flexibility, adapting to various fuel types and load conditions without compromising performance. Their robust construction ensures minimal downtime, while advanced designs reduce fouling and corrosion risks. Real-world data from industrial applications demonstrates that air preheaters can extend boiler lifespan by reducing thermal stress on components. Furthermore, governments and organizations worldwide incentivize the adoption of energy-efficient technologies like air preheaters through tax credits and grants. By selecting a high-quality air preheater boiler, industries can future-proof their operations, achieve greener production, and gain a competitive edge in the market.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Leakage free air preheater solutions from top bran...

More

Compare top frame plate heat exchanger models for ...

More

Plate heat exchangers boost industrial energy effi...

More

Commercial heat exchangers boost energy efficiency...

More

Gasketed plate heat exchangers boost industrial ef...

More

Plate heat exchangers cut industrial energy use, l...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe air preheater boiler has significantly improved our plant's efficiency. Installation was smooth, and the performance exceeded our expectations.

Emily Johnson

Plant ManagerGreat product! The air preheater boiler reduced our fuel consumption and emissions. Minor adjustments were needed, but overall very satisfied.

Michael Brown

HVAC TechnicianThis air preheater boiler is a game-changer for our heating systems. Reliable, durable, and easy to maintain. Highly recommend!

Sarah Davis

Environmental ConsultantThe air preheater boiler helped our client meet sustainability goals. Efficient and eco-friendly, though the initial cost was a bit high.