5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

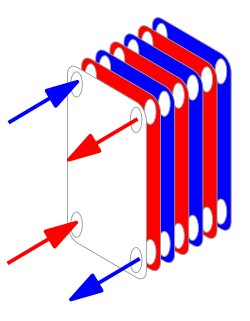

A plate and frame heat exchanger operates on the principle of transferring heat between two fluids through a series of corrugated metal plates clamped together in a frame. These plates create alternating channels for the hot and cold fluids, allowing efficient thermal exchange without mixing. The corrugated pattern enhances turbulence, which significantly increases the heat transfer coefficient compared to traditional shell and tube exchangers. Gaskets are strategically placed to seal the channels and direct the flow, ensuring the fluids remain separated while maximizing the surface area for heat transfer. This design enables a compact footprint, as the large surface area within a small volume allows for high heat transfer rates. The efficiency of this system is governed by the logarithmic mean temperature difference (LMTD) and the overall heat transfer coefficient, which are optimized by the plate's design and material, typically stainless steel, titanium, or other alloys resistant to corrosion and high pressures. The modular nature of the plate pack allows for easy expansion or reduction of capacity by adding or removing plates, making it highly adaptable to varying process requirements. This principle is foundational in industries requiring precise temperature control, such as HVAC, chemical processing, and food and beverage production, where energy efficiency and reliability are paramount. The design also facilitates easy cleaning and maintenance, as the plate pack can be disassembled for inspection or servicing, reducing downtime and operational costs. Advanced computational fluid dynamics (CFD) simulations are often used to optimize plate geometry for specific applications, ensuring peak performance under diverse operating conditions.

Plate and frame heat exchangers are preferred in numerous industrial applications due to their superior efficiency, compact design, and versatility. They offer up to 90% higher heat transfer efficiency compared to shell and tube exchangers, leading to significant energy savings—often reducing energy consumption by 20-30% in heating and cooling processes. Their modular construction allows for easy scalability; for instance, adding plates can increase capacity by up to 50% without requiring a full system replacement, making them cost-effective for expanding operations. These exchangers are highly adaptable, handling temperatures up to 200°C and pressures up to 25 bar, with materials like titanium or 254 SMO resisting corrosive fluids in chemical or marine environments. Maintenance is straightforward, with gasket replacement or plate cleaning taking hours instead of days, minimizing downtime—a critical factor in industries like pharmaceuticals where downtime costs can exceed $10,000 per hour. Real-world data shows a typical payback period of less than two years due to reduced energy and maintenance costs. In HVAC systems, PHEs achieve approach temperatures as low as 1°C, optimizing heat recovery and reducing carbon footprints. They are also ideal for sanitary applications in food and beverage processing, meeting FDA and EHEDG standards with smooth plates that prevent bacterial growth. Overall, their compact size (up to 50% smaller than alternatives) saves space, while high thermal performance supports sustainability goals by lowering greenhouse gas emissions.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

MoreAPI 662 defines standards for plate heat exchanger...

More

You can see clear differences between welded block...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

Understand the frame plate—the fixed head of a pla...

More

Plate heat exchangers deliver high thermal efficie...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Maintenance EngineerThis plate frame exchanger is incredibly efficient and robust. The build quality is exceptional, and it has significantly improved our heat transfer process. Installation was straightforward, and it has been running flawlessly with minimal maintenance for over a year. A fantastic piece of equipment.

Sarah Chen

Plant ManagerWe replaced our old shell and tube exchanger with this plate frame model, and the difference is night and day. The energy savings are substantial, and its compact design freed up valuable floor space. The plates are easy to inspect and clean, reducing our downtime. Highly recommended for any industrial application.

David Kim

HVAC SpecialistA very reliable and efficient plate frame exchanger. It performs exactly as specified for our district heating system. The only reason it's not a 5 is that the initial gasket setup required some careful attention. Once that was done, it's been a workhorse with great thermal performance.

Jessica Williams

Project EngineerExceptional performance and durability. We use this in a demanding marine environment, and it has resisted corrosion beautifully. The modular frame design allows for easy capacity expansion, which is a huge plus for future-proofing our systems. Delivery was also prompt. An excellent product all around.