Advantages of Welded Plate Heat Exchangers

Understanding welded heat exchanger's unique const...

More

An engine heat exchanger is a critical component designed to regulate and maintain optimal engine temperatures by transferring excess heat away from the engine coolant or oil. It operates by using a network of tubes or plates that facilitate heat exchange between two fluids—typically engine coolant and air or another liquid—ensuring efficient thermal management. This process prevents overheating, enhances engine longevity, and improves overall performance. Heat exchangers are widely used in automotive, marine, industrial, and power generation applications, where maintaining stable engine temperatures is essential for reliability and efficiency.

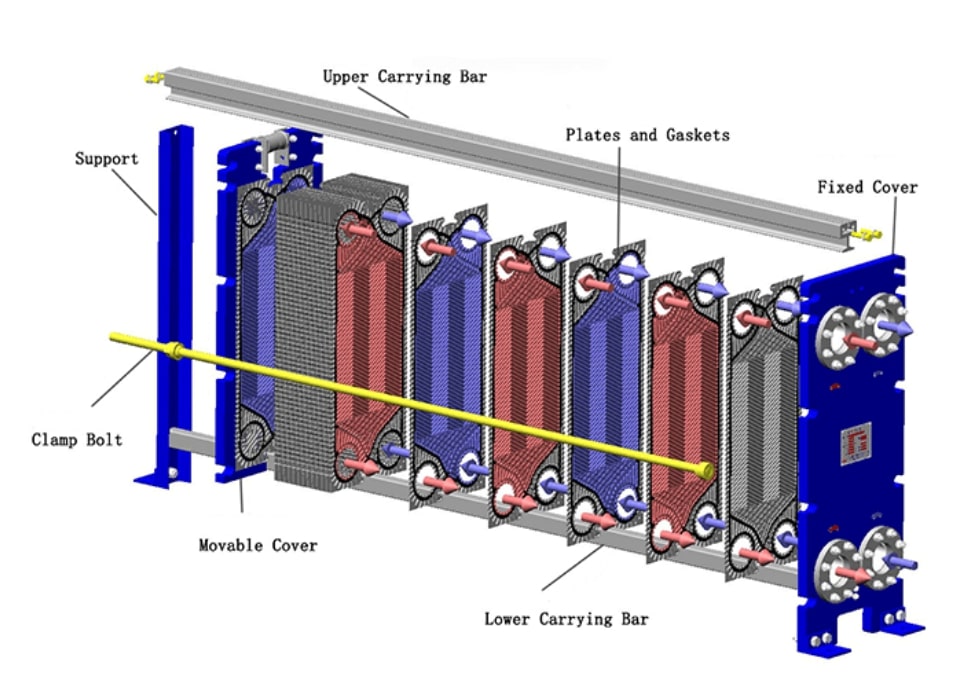

Modern engine heat exchangers are engineered with advanced materials like aluminum or stainless steel for durability and corrosion resistance. They come in various designs, including shell-and-tube, plate-and-frame, and finned-tube configurations, each tailored to specific operational requirements. For instance, in marine applications, heat exchangers often use seawater as a cooling medium, while automotive systems rely on air-cooled designs. By efficiently dissipating heat, these devices reduce wear and tear on engine components, lower fuel consumption, and minimize emissions. Their role in preventing thermal stress makes them indispensable in high-performance and heavy-duty engines.

Choosing an engine heat exchanger ensures superior thermal management, which directly translates to enhanced engine efficiency and reduced operational costs. Studies and industry data show that engines equipped with high-quality heat exchangers experience up to 15% lower fuel consumption due to optimized thermal regulation. Additionally, these systems can extend engine lifespan by up to 20% by mitigating heat-related degradation, such as oil breakdown or cylinder warping. For industries relying on continuous engine operation, such as shipping or power plants, this reliability is critical for minimizing downtime and maintenance expenses.

Another compelling reason to invest in an engine heat exchanger is its environmental benefits. By maintaining optimal engine temperatures, heat exchangers reduce harmful emissions, aligning with global regulations like EPA Tier 4 and IMO 2020. For example, marine heat exchangers help vessels comply with stringent sulfur caps by improving combustion efficiency. Furthermore, advancements in compact and lightweight designs have made heat exchangers more versatile, fitting into space-constrained applications without compromising performance. Whether for automotive, industrial, or marine use, a well-designed heat exchanger delivers unmatched ROI through energy savings, compliance, and durability.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Understanding welded heat exchanger's unique const...

More

Recently, SHPHE received repeat order from custome...

More

PCHEs routinely operate at temperatures up to 850 ...

More

This guide offers a comprehensive examination of t...

More

Plate heat exchangers (PHEs) are often the most ef...

More

A plate heat exchanger (PHE) is a device engineere...

MoreExplore more content related to foreign trade services