Advantages of Welded Plate Heat Exchangers

Understanding welded heat exchanger's unique const...

More

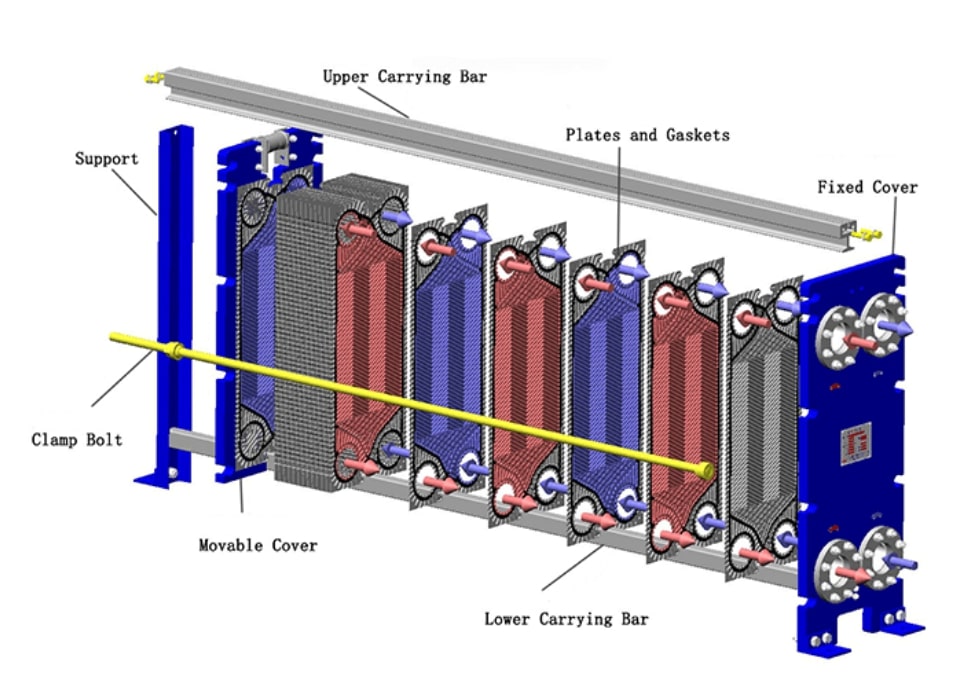

A primary heat exchanger is a critical component in heating, ventilation, and air conditioning (HVAC) systems, as well as industrial processes. It facilitates the transfer of thermal energy between two or more fluids (liquids or gases) without allowing them to mix. Typically constructed from durable materials like stainless steel or aluminum, primary heat exchangers are designed to withstand high temperatures and pressures, ensuring long-term reliability. They are commonly used in boilers, furnaces, and heat recovery systems to maximize energy efficiency by capturing and reusing waste heat.

Primary heat exchangers play a pivotal role in reducing energy consumption and operational costs. For instance, in condensing boilers, they extract heat from flue gases, lowering fuel usage by up to 30% compared to non-condensing models. Industrial applications, such as chemical processing or power generation, rely on them to maintain precise temperature control, improving process efficiency. Modern designs incorporate advanced features like turbulators or finned tubes to enhance heat transfer rates, making them indispensable in energy-intensive sectors. Their versatility extends to renewable energy systems, including solar thermal and geothermal installations, where they optimize heat exchange between fluids.

Selecting a primary heat exchanger offers unmatched advantages in performance, durability, and cost savings. Industry data shows that systems equipped with high-quality heat exchangers can achieve thermal efficiencies exceeding 90%, significantly cutting energy bills. For example, a study by the U.S. Department of Energy revealed that heat recovery systems with primary exchangers reduce industrial energy waste by 20–50%. Their robust construction minimizes maintenance needs, with lifespans often exceeding 15 years in harsh environments.

Beyond efficiency, primary heat exchangers comply with stringent environmental regulations, such as EPA standards, by reducing greenhouse gas emissions. They are also adaptable to diverse applications, from residential HVAC to large-scale industrial plants. Leading manufacturers like Alfa Laval and SWEP provide certified exchangers with warranties, ensuring reliability. Real-world case studies, such as their use in district heating networks, demonstrate annual savings of over $1 million in energy costs. By investing in a primary heat exchanger, businesses and homeowners alike benefit from lower operational expenses, reduced carbon footprints, and long-term sustainability.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Understanding welded heat exchanger's unique const...

More

Recently, SHPHE received repeat order from custome...

More

PCHEs routinely operate at temperatures up to 850 ...

More

This guide offers a comprehensive examination of t...

More

Plate heat exchangers (PHEs) are often the most ef...

More

Plate heat exchangers (PHEs) are vital components ...

MoreExplore more content related to foreign trade services