Understanding api 662 for plate heat exchangers

API 662 defines standards for plate heat exchanger...

More

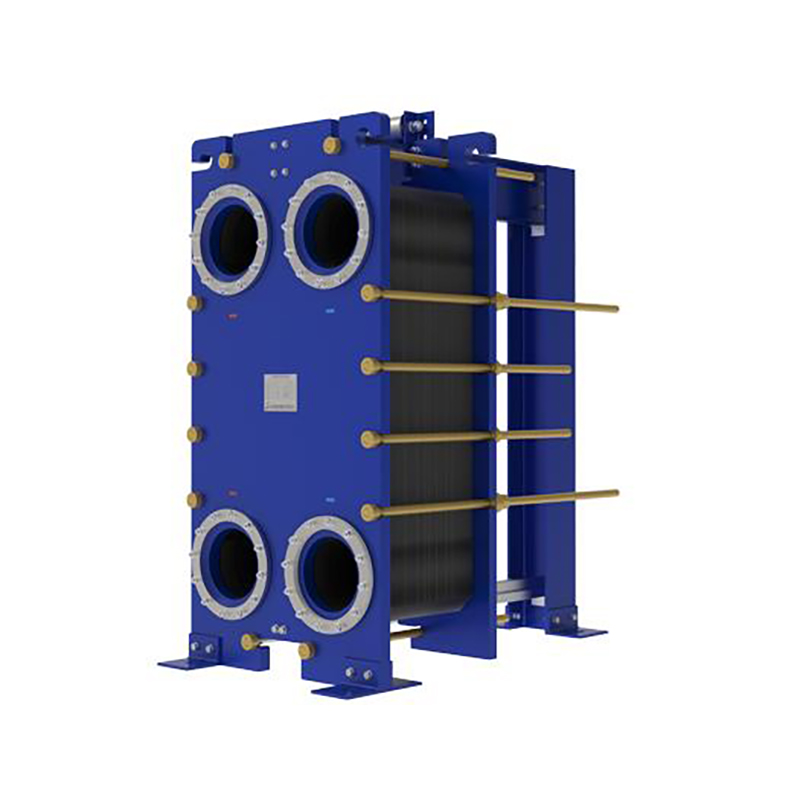

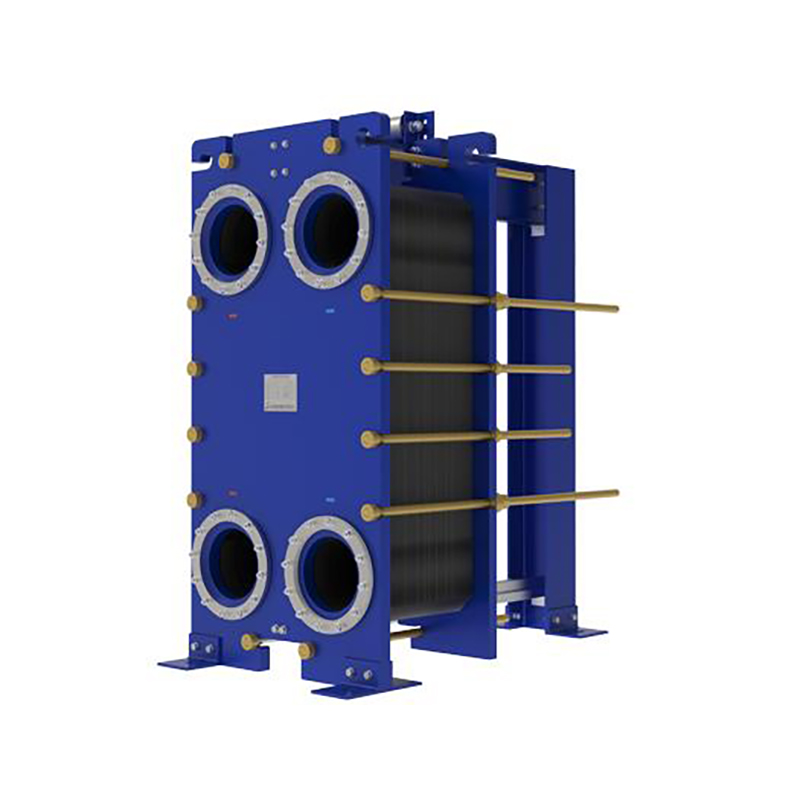

Modern heat exchangers operate on the fundamental principle of transferring thermal energy between two or more fluids without mixing them, utilizing a solid barrier to facilitate efficient heat exchange. This core principle is applied across various advanced designs, including shell and tube, plate and frame, and compact microchannel configurations, each engineered to maximize surface area and optimize fluid dynamics for superior thermal performance. The operational mechanism relies on conduction through the separating walls and convection from the flowing fluids, governed by the laws of thermodynamics to ensure minimal energy loss. Contemporary designs incorporate sophisticated materials such as stainless steel, titanium, and advanced polymers to withstand extreme temperatures, pressures, and corrosive environments, thereby enhancing durability and operational reliability. Computational fluid dynamics (CFD) and precision engineering enable the customization of flow patterns, turbulence induction, and temperature gradients, ensuring that modern exchangers achieve unprecedented levels of efficiency in both heating and cooling applications across diverse industrial sectors.

The principle of modern heat exchangers is realized through innovative engineering that prioritizes energy efficiency, thermal precision, and operational adaptability. In shell and tube exchangers, for instance, multiple tubes enclosed within a cylindrical shell create a large surface area for heat transfer, with baffles strategically placed to enhance turbulence and reduce fouling, leading to efficiency rates often exceeding 90% in applications like power generation and chemical processing. Plate heat exchangers utilize corrugated plates stacked together to form channels, promoting high turbulence and efficient heat transfer with a compact footprint; these systems can achieve heat transfer coefficients up to 3-4 times higher than traditional designs, according to industry data from HVAC and refrigeration sectors. Microchannel heat exchangers, prevalent in automotive and aerospace industries, employ channels with diameters as small as 100 micrometers, leveraging phase change and enhanced conductivity to achieve thermal efficiencies of 95% or higher while reducing material usage by up to 50%. Advanced simulations allow for the optimization of flow distribution and minimization of thermal resistance, ensuring that temperature differentials are maintained within narrow margins, often as low as 1-2°C, which is critical in precision processes such as pharmaceutical manufacturing or data center cooling. Real-world data from energy audits show that modern plate exchangers can reduce energy consumption by 20-30% in heating, ventilation, and air conditioning (HVAC) systems, while compact models in renewable energy applications, like geothermal heat pumps, achieve coefficients of performance (COP) above 4.0, significantly lowering operational costs and environmental impact.

Modern heat exchangers are indispensable due to their unparalleled energy efficiency, cost-effectiveness, and adaptability to stringent environmental regulations, making them a cornerstone of sustainable industrial operations. Data from the U.S. Department of Energy indicates that industrial heat exchange systems account for approximately 40-50% of total energy usage in manufacturing sectors, and upgrading to modern designs can yield energy savings of 15-25%, directly reducing greenhouse gas emissions and operational expenses. In the chemical and petrochemical industries, for example, advanced shell and tube exchangers handle high-pressure and high-temperature fluids (up to 600°C and 300 bar) with thermal efficiencies over 85%, minimizing downtime and maintenance costs while ensuring process safety. The HVAC and refrigeration sectors benefit from plate heat exchangers' compact size and high effectiveness (often rated at 90-95%), which enhance system performance and comply with global standards like the EU's F-Gas Regulation by reducing refrigerant charges and leakage risks. Additionally, in renewable energy applications such as solar thermal plants or waste heat recovery systems, modern exchangers achieve heat recovery rates of 70-80%, converting otherwise lost energy into usable power and supporting circular economy goals. Real-world case studies from food processing facilities show that stainless steel plate exchangers improve pasteurization efficiency by 30%, reducing water and energy consumption while meeting strict hygiene standards, and in data centers, liquid cooling systems with microchannel exchangers cut cooling energy use by up to 40%, addressing the escalating thermal management demands of AI and computing infrastructure. With global market projections valuing the heat exchanger industry at $28.9 billion by 2027 (Grand View Research), their adoption is driven by tangible returns on investment, often with payback periods under two years, and alignment with international sustainability initiatives like the Paris Agreement.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

API 662 defines standards for plate heat exchanger...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

You can see clear differences between welded block...

More

Plate heat exchanger gaskets perform 5 key roles: ...

More

Gasketed plate heat exchangers boost industrial ef...

More

What is a heat exchanger? It's a device that trans...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Chen

HVAC Design EngineerThe compact design and exceptional thermal efficiency of these modern plate heat exchangers have revolutionized our HVAC system designs. The corrosion-resistant materials ensure longevity even in demanding environments.

Sarah Johnson

Process EngineerImplementing these microchannel heat exchangers has drastically reduced energy consumption and the footprint of our cooling systems. Their reliability is unmatched, leading to significant operational cost savings.

David Williams

Maintenance ManagerThe ease of maintenance and cleaning is a major advantage. The welded plate design eliminates gasket issues we had with older models, greatly reducing downtime for our production line.

Emily Rodriguez

R&D Project LeadThe advanced thermal performance and precise temperature control are perfect for our sensitive laboratory processes. The integration of smart monitoring capabilities provides invaluable data for optimizing our research.