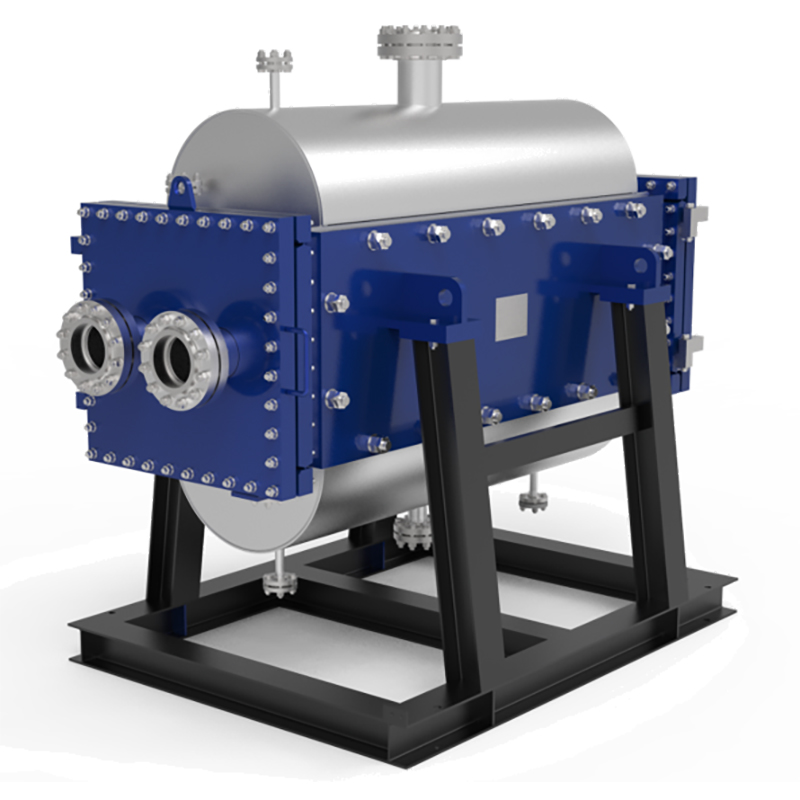

Comparing welded block and gasketed plate heat exchangers

You can see clear differences between welded block...

More

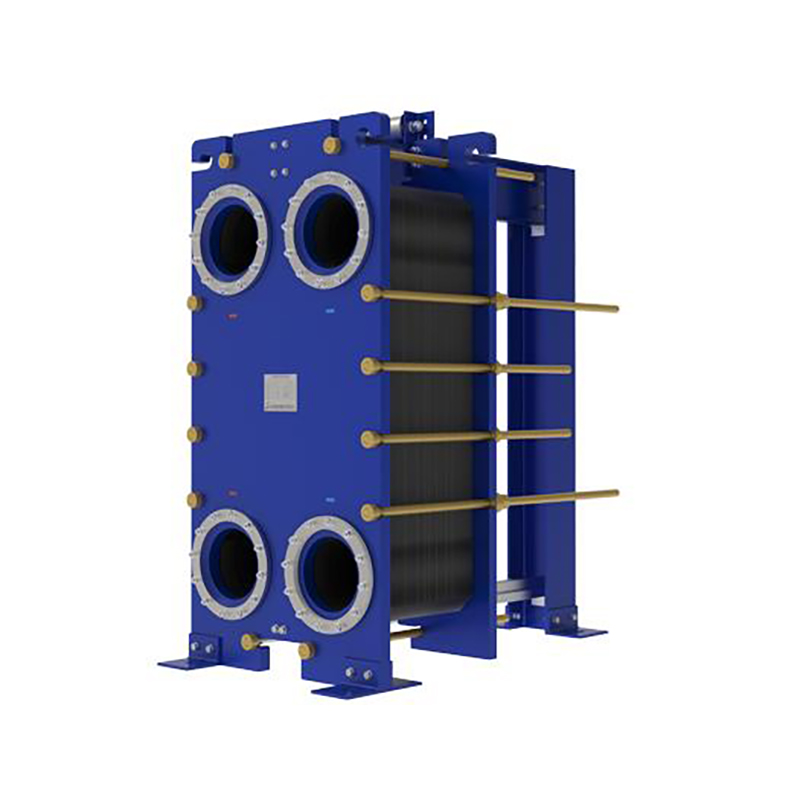

A plate and frame chiller is a type of heat exchanger specifically engineered for efficient temperature control in industrial processes. It is constructed from a series of corrugated metal plates compressed together within a sturdy frame, creating alternating channels for the process fluid (the product being cooled, such as beer, syrup, or chemicals) and the cooling medium (typically water or glycol). This design facilitates a highly efficient transfer of thermal energy from the warmer process fluid to the cooler medium. The modular plate pack is sealed by gaskets, which direct the flow of the two liquids and prevent them from mixing. Renowned for their compact footprint and superior thermal efficiency compared to shell and tube models, these chillers are a cornerstone of precise cooling in industries like food and beverage, chemical processing, and pharmaceuticals. Their operational principle is based on conductive heat transfer through the thin metal plates, with the corrugated pattern inducing turbulent flow in the liquids. This turbulence is key to maximizing heat transfer rates and minimizing fouling, as it helps to scrub the plate surfaces clean. The unit's capacity can be easily adjusted by adding or removing plates, making it a scalable solution for varying production demands. This adaptability, combined with their efficiency, makes plate and frame chillers an indispensable component for applications requiring strict temperature management, from post-fermentation wort cooling in breweries to final product cooling in dairy production, ensuring product quality and consistency.

The advantages of plate and frame chillers are substantial, making them a preferred choice over other heat exchanger types in numerous applications. Their primary benefit is exceptional thermal efficiency, often achieving efficiency rates of 90% or higher. This high performance is a direct result of the turbulent flow and large surface area created by the tightly packed, corrugated plates. This design allows for a very close temperature approach, meaning the outgoing process fluid can reach a temperature within 1-2°F (approximately 0.5-1°C) of the incoming coolant temperature, a feat difficult for shell and tube chillers to match. This maximizes the utility of the cooling medium and significantly reduces energy consumption and operational costs. Furthermore, their compact and modular design offers a significant space-saving advantage, often being up to 50% smaller than a shell and tube unit of equivalent capacity. This smaller footprint translates to lower installation costs and greater flexibility in plant layout. Maintenance is also a major strong point; the entire plate pack can be easily opened for inspection, cleaning, or service without special tools. This accessibility drastically reduces downtime. If a plate becomes damaged or a gasket fails, only the individual component needs replacement, not the entire unit, leading to lower long-term maintenance expenses. The versatility in configuration, including the ability to handle multiple duties or phases within a single frame, adds to their operational value, providing a cost-effective and reliable cooling solution for a wide range of duties and duties.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

You can see clear differences between welded block...

More

The dimple plate heat exchanger, also known as the...

More

Compare steam plate heat exchanger vs shell and tu...

More

Plate heat exchanger gaskets perform 5 key roles: ...

More

Plate and frame heat exchangers offer higher effic...

More

API 662 defines standards for plate heat exchanger...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Reynolds

BrewmasterThis plate and frame chiller is an absolute game-changer for our craft brewery. The cooling efficiency is incredible, allowing us to rapidly drop wort temperatures and maintain perfect clarity. The build quality is robust and it's incredibly easy to clean between batches. Highly recommended for any serious brewing operation.

Sarah Chen

Dairy Production ManagerOutstanding performance in our dairy processing line. The sanitary design and easy disassembly make cleaning and maintenance a breeze. We've seen a 30% improvement in our cooling cycle times since installation. The stainless steel construction holds up perfectly to our rigorous sanitation protocols.

David Rodriguez

Chemical EngineerExcellent heat transfer capabilities for our chemical processing applications. The modular design allows us to easily adjust capacity as needed. The only minor drawback is the initial setup complexity, but once operational, it performs flawlessly. Corrosion resistance has been perfect for our aggressive chemical environment.

Emily Watkins

WinemakerPerfect temperature control for our premium wine production. The gentle cooling preserves delicate aromas and flavors that we struggled to maintain with our previous system. The compact design saves valuable space in our production facility, and the energy efficiency has reduced our operating costs significantly.