Comparing welded block and gasketed plate heat exchangers

You can see clear differences between welded block...

More

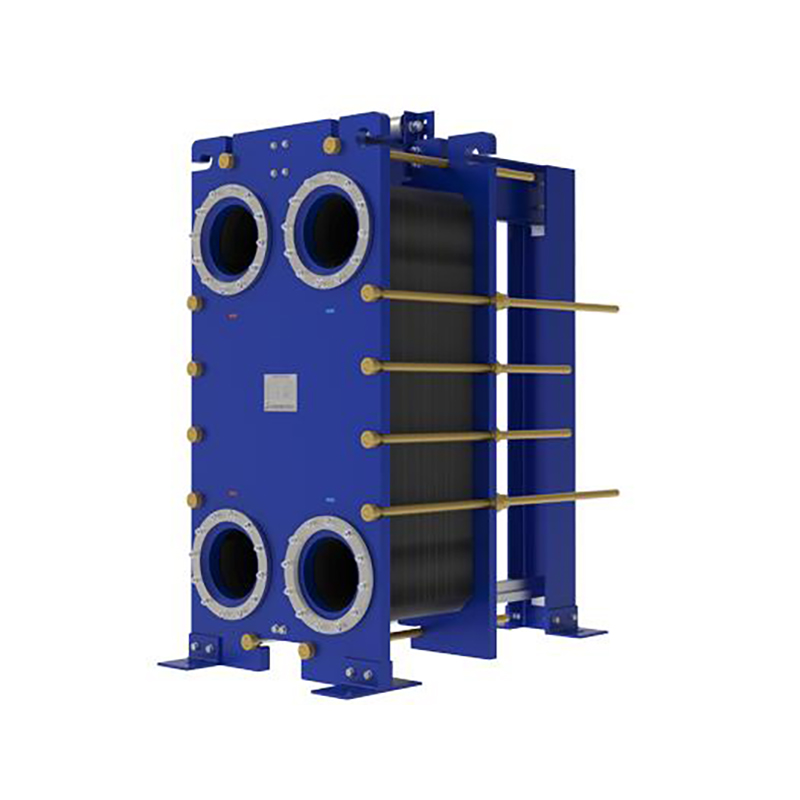

A gasketed heat exchanger is a type of plate heat exchanger designed with gaskets between plates to seal and direct fluid flow. These exchangers consist of multiple thin plates stacked together, creating alternating channels for hot and cold fluids to transfer heat efficiently. Gasketed heat exchangers are widely used in industries such as HVAC, chemical processing, food and beverage, and power generation due to their compact design, scalability, and ease of maintenance. The gaskets ensure leak-proof operation while allowing for quick disassembly for cleaning or plate replacement, making them ideal for applications requiring frequent maintenance or fluid changes.

Gasketed heat exchangers offer superior thermal performance compared to traditional shell-and-tube models, with heat transfer coefficients up to 3-5 times higher. According to industry data, they can achieve efficiency rates of over 90% in many applications. Their modular design allows for easy capacity expansion by adding or removing plates, providing flexibility for varying process demands. Common materials include stainless steel, titanium, and nickel alloys, ensuring compatibility with corrosive or high-purity fluids. Leading manufacturers like Alfa Laval, SWEP, and Danfoss provide gasketed heat exchangers compliant with international standards such as ASME, PED, and EHEDG.

Gasketed heat exchangers provide numerous benefits, including energy savings, reduced operational costs, and enhanced sustainability. Their high thermal efficiency minimizes energy consumption, with studies showing up to 40% lower energy usage compared to conventional systems. The compact footprint saves up to 80% space versus shell-and-tube exchangers, making them ideal for facilities with limited space. Additionally, their lightweight design reduces structural support requirements and installation costs.

The gasketed design ensures easy maintenance, with gasket replacement taking significantly less downtime than repairing welded or brazed units. Industry reports indicate maintenance cost reductions of up to 30% over the equipment's lifespan. These exchangers also support hygienic applications, meeting strict FDA and 3-A sanitary standards for food, pharmaceutical, and dairy processing. With customizable configurations and materials, they adapt to diverse temperature and pressure ranges (typically -40°C to 200°C and 25 bar max). Their scalability and eco-friendly operation, including reduced refrigerant charges, align with global energy efficiency regulations like Eurovent and LEED certifications.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

You can see clear differences between welded block...

More

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

Ignoring a fouled heat exchanger causes high energ...

More

A gasketed plate and frame heat exchanger improves...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe gasketed heat exchanger is incredibly efficient and easy to maintain. Perfect for our industrial applications.

Emily Johnson

Process EngineerGreat performance and durability. The gasketed design makes cleaning and servicing a breeze. Highly recommended!

Michael Brown

HVAC TechnicianThis heat exchanger has significantly improved our system's efficiency. The gasketed construction ensures a tight seal and minimal leaks.

Sarah Davis

Plant ManagerReliable and cost-effective. The gasketed heat exchanger has reduced downtime and maintenance costs in our facility.