5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

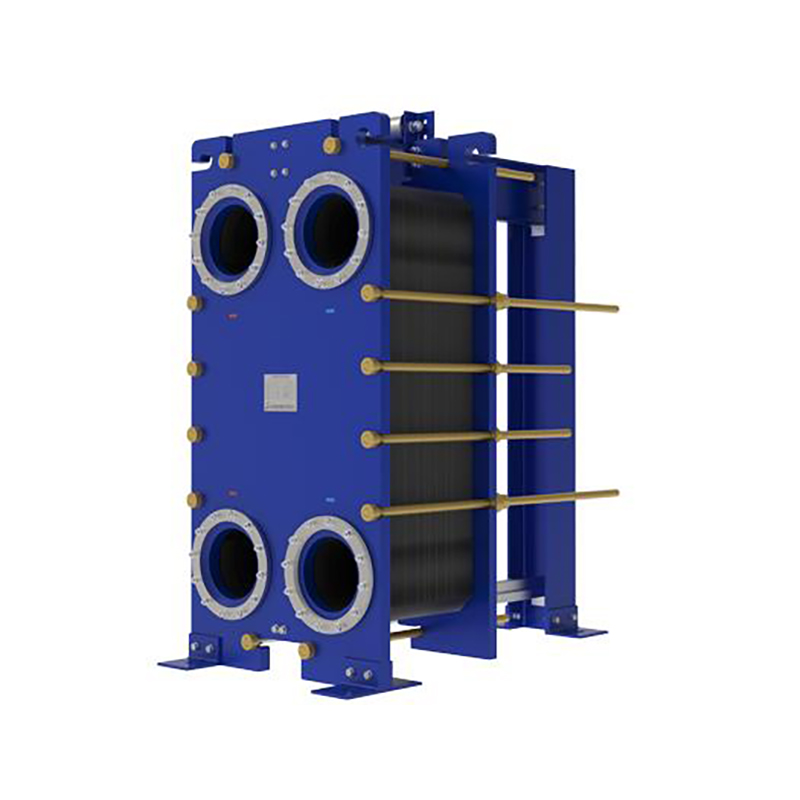

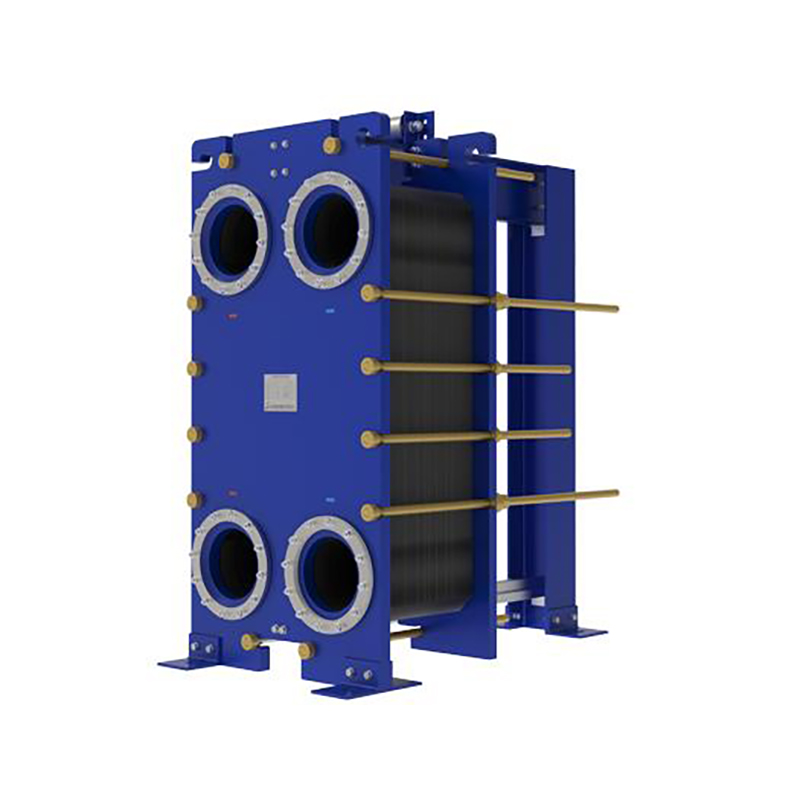

A Plate and Shell Heat Exchanger (PSHE) is a highly efficient, compact thermal transfer device that ingeniously combines the best features of traditional shell and tube exchangers with those of modern plate heat exchangers. Its core construction consists of a bundle of corrugated or embossed heat transfer plates, typically laser-welded together into a circular cassette. This plate pack is then housed within a cylindrical pressure vessel (the shell). One fluid flows through the alternating channels between the plates (the plate side), while the second fluid flows over the outside of the plate bundle within the shell (the shell side), facilitating heat transfer. This hybrid design is engineered to handle extreme conditions, making it a superior solution for applications involving high pressures, high temperatures, or challenging media where conventional gasketed plate heat exchangers would fail. Industries such as oil and gas, power generation, chemical processing, and HVAC increasingly favor PSHEs for their robustness and performance. They are particularly prevalent in duties like compressor cooling, boiler feedwater heating, heat recovery, and as evaporators or condensers in refrigeration systems. The design's scalability allows it to serve a wide range of duties, from modest capacities to very large industrial projects, providing a versatile and reliable answer to complex heat transfer challenges.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

You can see clear differences between welded block...

MoreAPI 662 defines standards for plate heat exchanger...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

Industries in 2025 achieve higher efficiency by ad...

More

What is a heat exchanger? It's a device that trans...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Maintenance EngineerExceptional thermal efficiency and robust construction. This plate and shell exchanger has significantly improved our heat transfer process with minimal maintenance requirements. Highly reliable under continuous operation.

Sarah Johnson

Plant ManagerOutstanding performance in high-pressure applications. The compact design saved valuable space while delivering superior heat recovery capabilities. Installation was straightforward with excellent manufacturer support.

David Rodriguez

HVAC Systems DesignerImpressive heat transfer coefficients and flexible configuration options. The unit integrates perfectly with our district heating system, providing consistent performance with energy savings exceeding 25% compared to previous solutions.

Emily Wang

Process TechnicianRemarkable corrosion resistance and easy maintenance access. The welded plate design eliminates gasket concerns while maintaining excellent thermal performance. Has operated flawlessly for 8,000+ hours in aggressive chemical environment.