SHPHE received repeat order from customer in Australia

Recently, SHPHE received repeat order from custome...

More

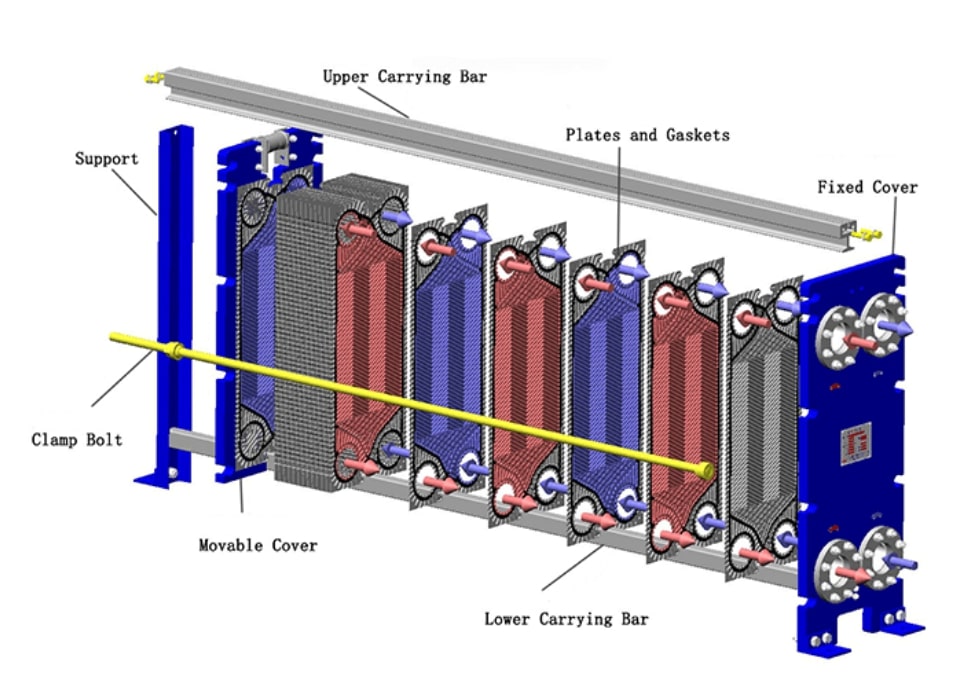

A stacked plate heat exchanger is a compact and highly efficient thermal transfer device designed for industrial and commercial applications. Unlike traditional shell-and-tube heat exchangers, it consists of multiple thin plates stacked together, creating alternating channels for hot and cold fluids. This design maximizes surface area for heat transfer while minimizing space requirements. Stacked plate heat exchangers are widely used in HVAC systems, power plants, chemical processing, and food & beverage industries due to their superior thermal performance, scalability, and ease of maintenance.

Stacked plate heat exchangers operate on the principle of conductive and convective heat transfer between fluids separated by corrugated metal plates. The plates are typically made of stainless steel, titanium, or other corrosion-resistant materials, ensuring durability in harsh environments. According to industry reports, these exchangers can achieve thermal efficiency rates of up to 90%, significantly higher than conventional designs. Their modular construction allows for easy expansion or reconfiguration, making them ideal for evolving industrial needs. Major manufacturers like Alfa Laval, SWEP, and Danfoss have advanced this technology, offering models that handle temperatures up to 350°C and pressures exceeding 25 bar.

Stacked plate heat exchangers offer unparalleled advantages in energy efficiency, cost savings, and operational flexibility. Their compact design reduces installation footprint by up to 50% compared to shell-and-tube units, as verified by ASHRAE studies. The high turbulence created by plate corrugations enhances heat transfer coefficients, often 3-5 times greater than traditional systems. This translates to lower energy consumption, with documented case studies showing 20-30% reductions in operating costs for facilities adopting this technology.

Additionally, stacked plate heat exchangers excel in hygienic applications, complying with FDA and EHEDG standards for food and pharmaceutical use. Their disassembly capability simplifies cleaning and inspection, reducing downtime. Market data from Grand View Research projects the global plate heat exchanger market to grow at 6.8% CAGR through 2030, driven by industrial energy optimization demands. Leading oil & gas companies report 15-20% longer service life with stacked plate designs versus conventional units, thanks to advanced gasket materials and laser-welded plate options that eliminate leakage risks. These factors make them the preferred choice for modern thermal management challenges.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Recently, SHPHE received repeat order from custome...

More

Traditional plate heat exchangers (PHEs) use gaske...

More

Plate heat exchangers (PHEs) are compact units con...

More

This guide offers a comprehensive examination of t...

More

Understanding welded heat exchanger's unique const...

More

Plate heat exchangers (PHEs) are often the most ef...

MoreExplore more content related to foreign trade services