Understanding api 662 for plate heat exchangers

API 662 defines standards for plate heat exchanger...

More

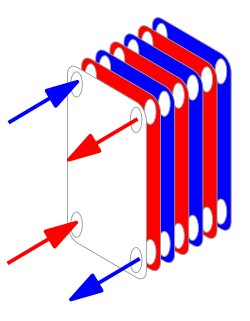

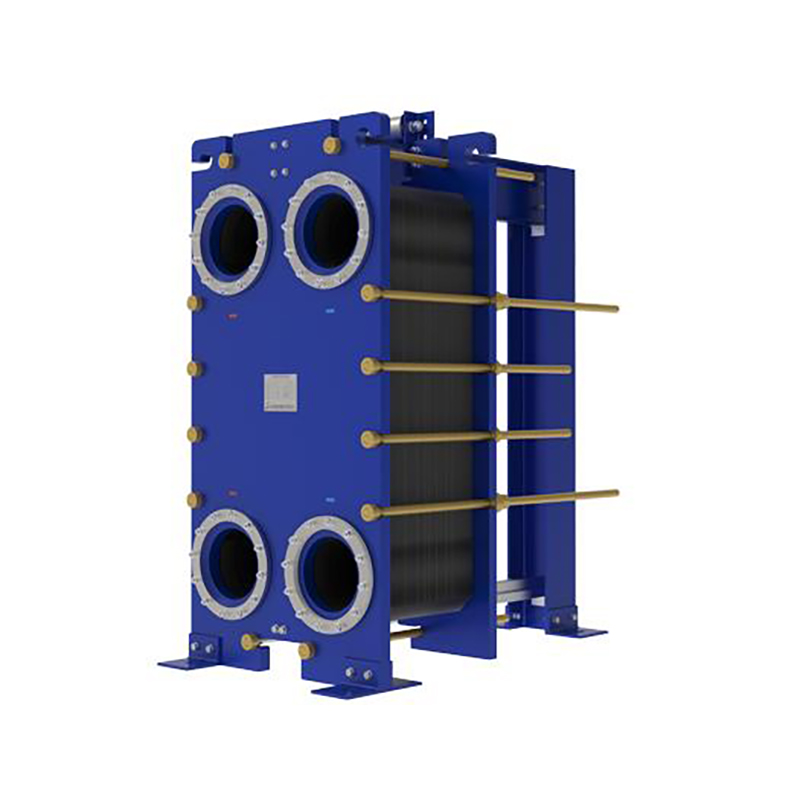

The principle of plate heat exchanger working revolves around efficient thermal energy transfer between two fluids without mixing them. This is achieved through a series of thin, corrugated metal plates stacked together, creating alternating channels for hot and cold fluids. The large surface area and turbulent flow induced by the plate design maximize heat transfer efficiency. Gaskets or welded seams ensure fluid separation, while the compact structure allows for high performance in a small footprint. Plate heat exchangers are widely used in industries like HVAC, food processing, and chemical manufacturing due to their adaptability and energy-saving capabilities.

Plate heat exchangers operate by directing fluids through parallel channels formed between plates, enabling rapid heat exchange. The corrugated pattern enhances turbulence, breaking up boundary layers and improving thermal conductivity. Materials like stainless steel, titanium, or nickel alloys are chosen based on fluid compatibility and temperature requirements. Advanced designs allow for easy maintenance, such as gasket replacement or plate cleaning, reducing downtime. Compared to shell-and-tube exchangers, plate versions offer up to 90% higher efficiency, with some models achieving temperature approach differences as low as 1°C. Real-world applications include dairy pasteurization, district heating, and marine engine cooling, where reliability and efficiency are critical.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

API 662 defines standards for plate heat exchanger...

More

Plate heat exchangers deliver high thermal efficie...

More

Understand the frame plate—the fixed head of a pla...

More

Plate heat exchangers boost industrial energy effi...

More

Heat exchangers transfer heat between fluids witho...

More

Industries in 2025 achieve higher efficiency by ad...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe plate heat exchanger works incredibly efficiently, reducing energy costs significantly. Highly recommended for industrial applications.

Emily Johnson

HVAC TechnicianGreat performance and easy maintenance. The plate heat exchanger is perfect for commercial HVAC systems.

Michael Brown

Process EngineerOutstanding heat transfer efficiency and compact design. Ideal for chemical processing plants.

Sarah Davis

Facility ManagerReliable and durable plate heat exchanger. It has improved our facility's thermal management system.