Understanding api 662 for plate heat exchangers

API 662 defines standards for plate heat exchanger...

More

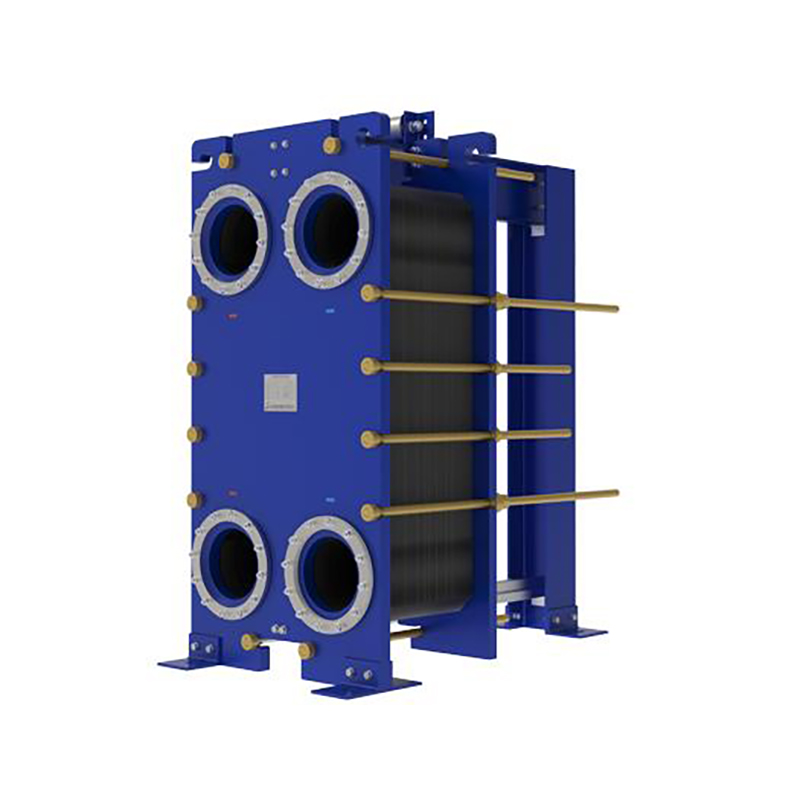

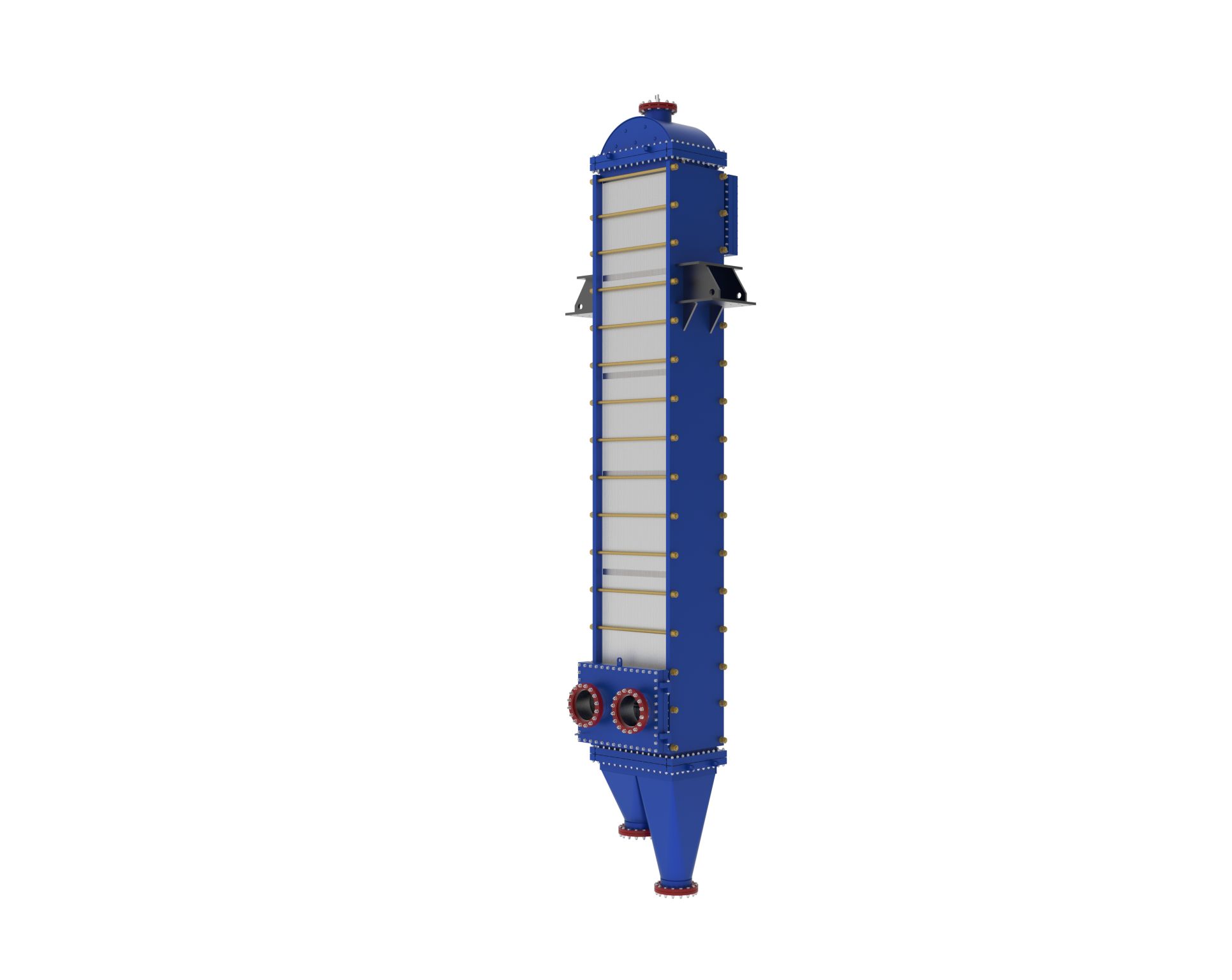

The principle of a compressed air heat exchanger revolves around transferring thermal energy between compressed air and a cooling medium (typically water or air) to reduce air temperature. This process ensures optimal system performance by preventing overheating, minimizing moisture buildup, and enhancing energy efficiency. Heat exchangers utilize conductive materials like aluminum or stainless steel to facilitate rapid heat transfer while maintaining structural integrity under high pressure.

Compressed air heat exchangers operate on the fundamentals of thermodynamics, leveraging convection and conduction to dissipate heat. As hot compressed air flows through the exchanger’s tubes or channels, the cooling medium absorbs excess heat, lowering the air temperature before it enters downstream equipment. This process is critical in industries like manufacturing, automotive, and food processing, where stable air temperatures are essential for operational reliability. Advanced designs incorporate finned surfaces or turbulators to maximize heat transfer efficiency, often achieving temperature reductions of 20–50°C depending on the model and airflow rate. By integrating these systems, businesses can mitigate thermal degradation of pneumatic tools and reduce energy consumption by up to 15%, as documented in case studies from Atlas Copco and Ingersoll Rand.

Compressed air heat exchangers are indispensable for maintaining system longevity and operational efficiency. Overheated air can damage pneumatic machinery, increase maintenance costs, and compromise product quality in sensitive applications like pharmaceuticals or electronics manufacturing. By cooling compressed air, these exchangers prevent lubricant breakdown in air compressors, reducing wear and tear. Additionally, they condense moisture from the air, minimizing corrosion in pipelines and equipment. According to industry reports, facilities using heat exchangers report 20–30% fewer downtime incidents due to thermal-related failures.

Beyond equipment protection, compressed air heat exchangers deliver significant energy savings. The U.S. Department of Energy highlights that cooling compressed air by just 5°C can reduce energy costs by 1–2%, as compressors require less power to maintain desired pressures. In large-scale operations, this translates to annual savings of thousands of dollars. Environmental benefits include lower carbon footprints, as efficient heat exchangers align with ISO 50001 energy management standards. Leading manufacturers like Kaeser and Gardner Denver emphasize their role in sustainable production, with some models achieving 98% thermal efficiency. For industries prioritizing reliability and cost-effectiveness, investing in a high-quality heat exchanger is a proven strategy to optimize compressed air systems.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

API 662 defines standards for plate heat exchanger...

More

Plate heat exchangers deliver high thermal efficie...

More

Plate heat exchangers boost industrial energy effi...

More

Maximize energy efficiency and cut costs by select...

More

Commercial heat exchangers boost energy efficiency...

More

Plate heat exchanger solutions boost efficiency, r...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe compressed air heat exchanger is incredibly efficient and has significantly reduced our energy costs. Highly recommended!

Emily Johnson

Plant ManagerThis heat exchanger works great for our compressed air system. Installation was straightforward, and it has improved our system's performance.

Michael Brown

HVAC TechnicianExcellent product! The compressed air heat exchanger is durable and performs beyond expectations. Our clients are very satisfied with the results.

Sarah Davis

Operations SupervisorWe've been using this heat exchanger for a few months now, and it has helped optimize our compressed air system. A solid investment for any industrial application.