Frame plate heat exchanger picks for top efficiency

Compare top frame plate heat exchanger models for ...

More

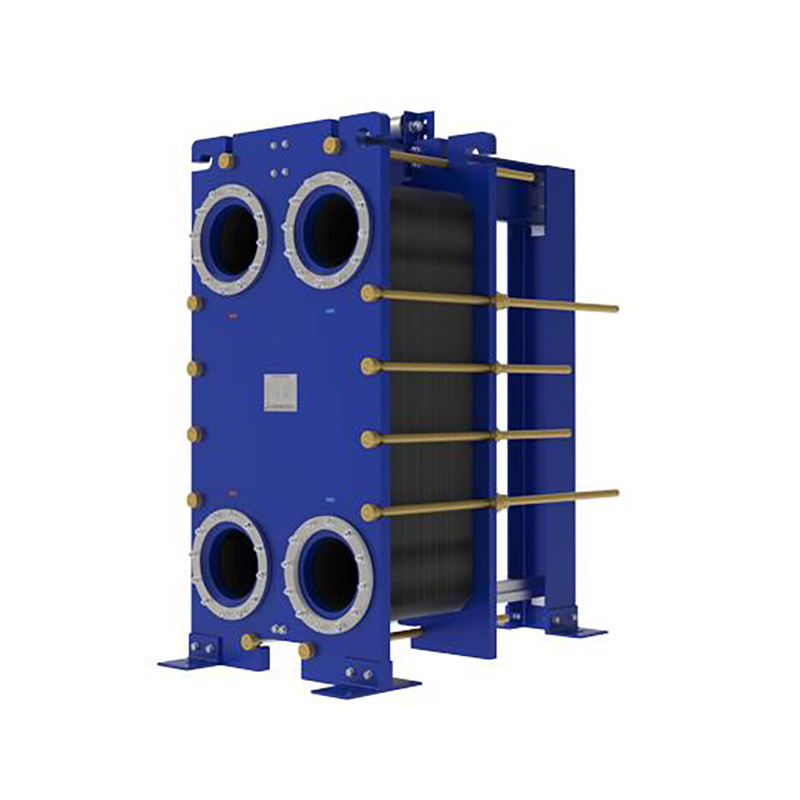

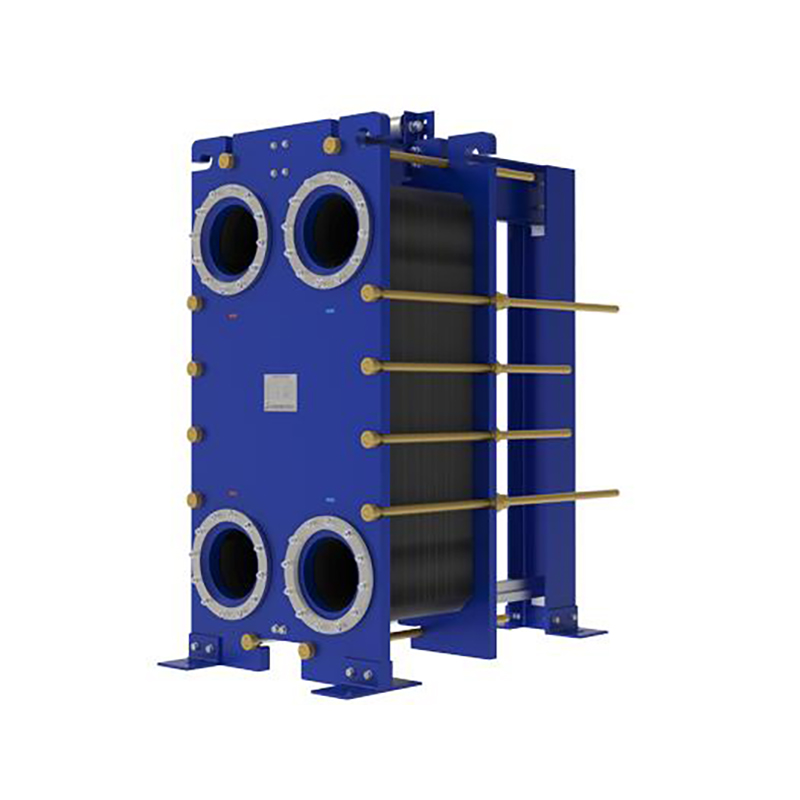

A liquid to liquid heat exchanger is a device designed to transfer heat between two separate liquid streams without allowing them to mix. These systems are widely used in industries such as chemical processing, power generation, HVAC, and food production, where precise temperature control is critical. The exchanger typically consists of plates, shells, or tubes that facilitate efficient thermal transfer while maintaining fluid separation. By leveraging the temperature difference between the two liquids, the system either heats or cools one stream using the other, optimizing energy efficiency. Common materials include stainless steel, titanium, or copper, chosen for their durability and thermal conductivity.

Liquid to liquid heat exchangers offer significant benefits, including high energy efficiency, compact design, and low maintenance requirements. Their ability to recover waste heat reduces operational costs and environmental impact, making them ideal for sustainable practices. For example, in HVAC systems, they can improve efficiency by up to 30% compared to traditional methods. The modular design allows for easy scaling, while corrosion-resistant materials extend lifespan. Additionally, these exchangers provide precise temperature control, critical for sensitive processes like pharmaceutical manufacturing. With minimal moving parts, they require less upkeep than air-based systems, ensuring long-term reliability and cost savings.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Compare top frame plate heat exchanger models for ...

More

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

Shanghai Heat Transfer stands out with its ISO9001...

More

You can see clear differences between welded block...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThis liquid-to-liquid heat exchanger is incredibly efficient and has significantly improved our system's thermal performance. Highly recommended!

Emily Johnson

Process EngineerThe heat exchanger works well for our chemical processing needs. Installation was straightforward, and it has been reliable so far.

Michael Brown

HVAC TechnicianExcellent product! The liquid-to-liquid heat exchanger has greatly enhanced our HVAC system's efficiency. Customer service was also top-notch.

Sarah Davis

Energy ConsultantThis heat exchanger is a great addition to our renewable energy projects. It performs as expected and has a compact design.