5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

An industrial air to air heat exchanger is a core component of energy recovery ventilation (ERV) systems, engineered to transfer thermal energy between two separate air streams without allowing them to mix. These robust systems are fundamental in large-scale commercial, manufacturing, and processing facilities where managing air quality, temperature, and operational costs is paramount. They primarily handle the exchange of sensible heat (temperature), and certain advanced models, like enthalpy wheels, can also transfer latent heat (moisture). The primary construction materials include aluminum, stainless steel, and composites, chosen for their excellent thermal conductivity and corrosion resistance to withstand harsh industrial environments. The core types prevalent in the market are plate heat exchangers, heat pipe heat exchangers, and rotary thermal wheels (regenerative), each offering distinct advantages in efficiency, maintenance, and application suitability. Their core function is to precondition incoming fresh outdoor air by harvesting energy from the exhaust air stream, leading to massive reductions in the heating and cooling load placed on primary HVAC systems.

Industrial air to air heat exchangers are not a luxury but a critical investment for any operation with significant ventilation requirements, such as factories, warehouses, chemical plants, pharmaceutical cleanrooms, and large agricultural settings. The driving force behind their adoption is the substantial energy savings they deliver; by recovering between 50% to 90% of the energy typically lost through exhaust, they drastically cut the consumption of fossil fuels and electricity used for space conditioning. For instance, data from the U.S. Department of Energy highlights that industrial ventilation and space heating can account for over 30% of a plant's total energy use, making heat recovery a primary target for efficiency upgrades. Beyond energy, they enhance process control by stabilizing internal temperatures and humidity levels, which is crucial for product quality in industries like food processing or electronics manufacturing. Furthermore, they improve indoor air quality (IAQ) by enabling a higher rate of fresh air dilution without the crippling energy penalty, ensuring a safer and more comfortable environment for workers and compliance with stringent OSHA ventilation standards.

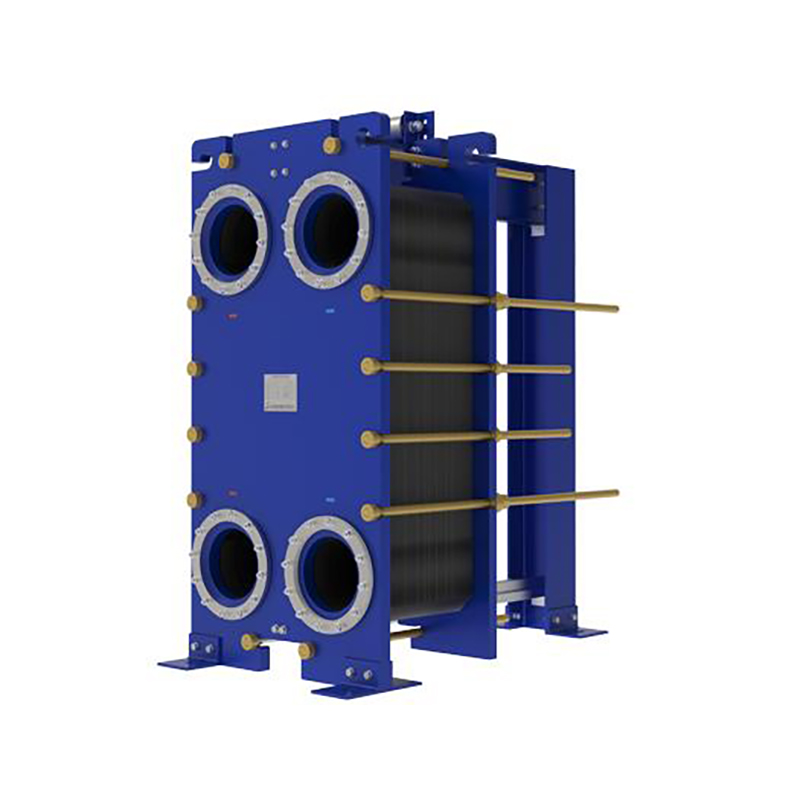

The fundamental operating principle of an industrial air to air heat exchanger is the transfer of thermal energy through a solid surface that separates a warm air stream from a cool one, following the laws of thermodynamics. In a typical cross-flow plate design, the most common type, the unit contains a series of parallel plates made of metal, creating alternating channels for the supply (outdoor) and exhaust (stale) air streams to pass through. These streams flow perpendicular to each other, never coming into physical contact. As the warm exhaust air moves through its channels, its thermal energy is absorbed by the plates. Simultaneously, the cool fresh air passing through the adjacent channels in the opposite direction absorbs this energy from the plates, thus warming up before it enters the facility. In a heating scenario, the exhaust air is warm from the building's interior, so it heats the plates, which then preheat the cold incoming air. In a cooling scenario, the hot outdoor air is cooled by the plates, which are being chilled by the cooler exhaust air from the air-conditioned space.

This process is highly efficient due to the large surface area provided by the plates and the excellent thermal conductivity of the materials used. For more demanding applications, a rotary heat exchanger (thermal wheel) is employed. This system features a large rotating cylinder filled with a medium with high heat capacity, such as corrugated aluminum. As the wheel slowly rotates, one half passes through the warm exhaust duct, absorbing heat. This heated section then rotates into the path of the cold incoming air, releasing the stored energy and preheating it. Some wheels are coated with a desiccant to also transfer moisture, addressing latent load. The efficiency of these systems is quantified by metrics like sensible effectiveness, which can range from 60% for basic cross-flow units to over 85% for counter-flow or high-performance rotary models, as per AHRI standards. This means for every 100 units of energy in the exhaust stream, 60 to 85 units are captured and reused, directly reducing the capacity and runtime required from boilers and chillers.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

You can see clear differences between welded block...

More

Ignoring a fouled heat exchanger causes high energ...

More

Gasketed plate heat exchangers boost industrial ef...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Reynolds

Facility ManagerThis industrial air-to-air heat exchanger has been a game-changer for our plant. The energy recovery efficiency is outstanding, significantly reducing our heating costs during winter. The build quality is robust and it has required zero maintenance in the 6 months since installation. Highly recommended for any large-scale operation.

Sarah Chen

HVAC EngineerAs an HVAC specialist, I'm thoroughly impressed with the performance and precision engineering of this unit. We specified it for a pharmaceutical clean room project, and it maintains perfect temperature and humidity control while drastically cutting energy consumption. The data from the control system proves its ROI will be under two years.

David Rodriguez

Plant EngineerA very effective and reliable piece of equipment. We installed it to handle heat recovery from our process exhaust. It's well-built, and the installation was straightforward with the provided manuals. It loses one star only because the initial shipping took longer than quoted, but the product itself is excellent.

Jennifer Williams

Sustainability OfficerIntegrating this heat exchanger was a key part of our strategy to reduce the carbon footprint of our data center. It allows us to use outside air for cooling for more hours of the year, minimizing mechanical refrigeration use. The unit is incredibly effective and the support from the technical team was top-notch during the design phase.