Comparing welded block and gasketed plate heat exchangers

You can see clear differences between welded block...

More

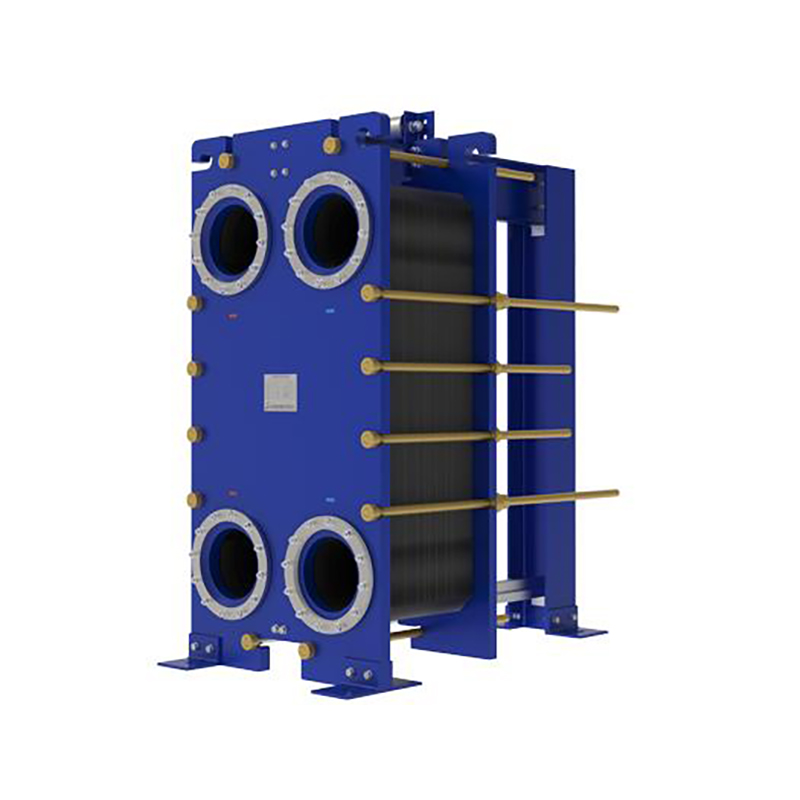

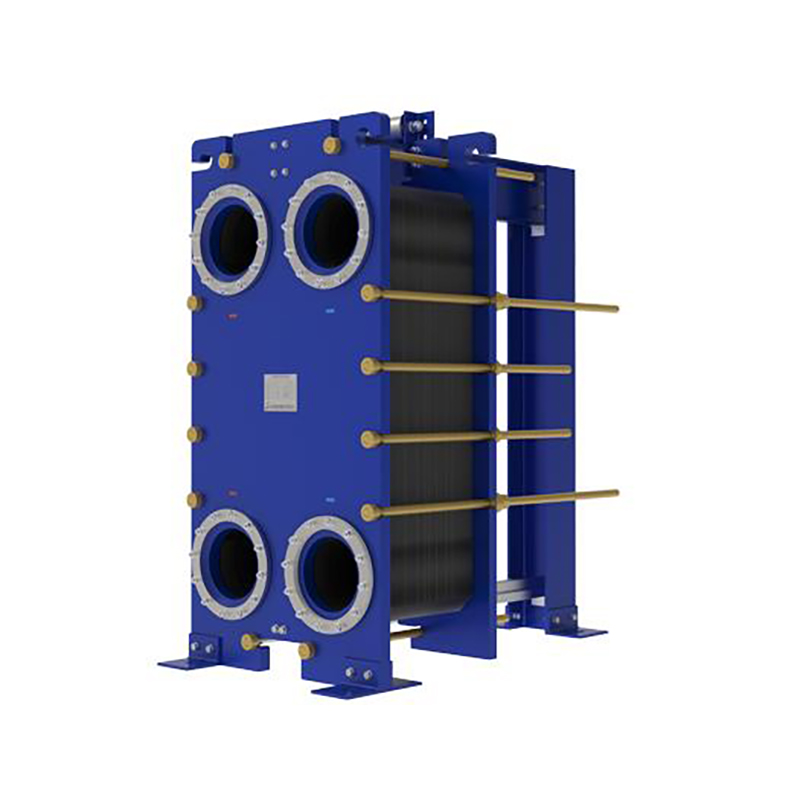

A gasketed plate and frame heat exchanger is a highly efficient thermal transfer device widely used in industries such as chemical processing, HVAC, food and beverage, and power generation. It consists of multiple corrugated metal plates stacked together, sealed by gaskets, and held within a rigid frame. This design maximizes surface area for heat exchange while maintaining compactness. According to market research by Grand View Research, the global plate and frame heat exchanger market was valued at $3.2 billion in 2022, with gasketed types dominating due to their versatility and cost-effectiveness. These exchangers excel in handling moderate pressure (typically up to 25 bar) and temperature ranges (-40°C to 260°C), making them ideal for liquid-to-liquid applications. Their modular construction allows for easy capacity expansion by adding or removing plates, a feature that reduces downtime during maintenance or process changes. Major manufacturers like Alfa Laval, SWEP, and Danfoss report energy savings of 30-50% compared to shell-and-tube models, with 90% thermal efficiency achievable in optimized configurations.

The working principle relies on counter-current flow through alternating channels formed between plates. Hot and cold fluids pass on opposite sides of each thin metal plate (usually 0.5-1.0mm thick stainless steel), with heat transferring through the plate material without fluid mixing. Chevron-pattern corrugations create turbulent flow at low Reynolds numbers (Re>10), enhancing heat transfer coefficients to 3,000-7,000 W/m²K – 3-5 times higher than shell-and-tube designs. Gaskets strategically direct flow into every second channel while sealing the periphery. Industry data shows typical approach temperatures of 1-2°C are achievable, with pressure drops ranging 0.3-1.0 bar per pass. The compact design achieves surface densities of 100-200 m²/m³, requiring 1/5th the space of equivalent shell-and-tube units. Modern models feature laser-welded plates for high-pressure applications and advanced gasket materials (EPDM, Nitrile, Viton) extending service life to 10-15 years. Real-world applications demonstrate 40-60% reduction in pumping energy compared to traditional exchangers, with maintenance time reduced by 70% due to the simple disassembly process.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

You can see clear differences between welded block...

More

Plate heat exchanger gaskets perform 5 key roles: ...

MoreAPI 662 defines standards for plate heat exchanger...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

Industries in 2025 achieve higher efficiency by ad...

More

What is a heat exchanger? It's a device that trans...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe gasketed plate and frame heat exchanger is incredibly efficient and easy to maintain. Perfect for our industrial applications!

Emily Johnson

Process EngineerGreat performance and compact design. The heat exchanger has significantly improved our system's thermal efficiency.

Michael Brown

HVAC TechnicianHighly reliable and durable. The gasketed plate and frame heat exchanger works flawlessly in our HVAC systems.

Sarah Davis

Plant ManagerExcellent heat transfer capabilities and easy to install. A great addition to our food processing plant.