Exploring the Benefits of Commercial Heat Exchangers in 2025

Commercial heat exchangers empower businesses to achieve energy cost savings and greater energy efficiency. Recent reports highlight the impact of improving energy efficiency through heat exchangers:

· Enhanced performance in industrial and building operations

·Reduced operational expenses due to lower maintenance needs

·Rising demand fueled by sustainability and regulatory standards

Commercial Heat Exchanger Types and Innovations

Plate Heat Exchangers from SHPHE

Shanghai Heat Transfer Equipment Co., Ltd. (SHPHE) manufactures plate heat exchangers that deliver outstanding performance in commercial settings. These units feature high pressure and temperature resistance, handling up to 1000 bar and temperatures from -196°C to 850°C. Their compact design saves up to 85% of space compared to traditional models. Microchannel technology, with channels as narrow as 0.4 mm, increases turbulence and optimizes heat transfer. All-welded, gasket-free construction ensures durability and minimal maintenance. SHPHE offers versatile material options, making these commercial heat exchangers suitable for diverse fluids in industries such as oil and gas, chemical processing, and food production.

Plate heat exchangers from SHPHE improve energy efficiency by maximizing thermal exchange and integrating easily into existing systems. Lower maintenance needs further reduce operational costs, supporting sustainability goals.

Feature | Description |

|---|---|

High Pressure & Temperature | Up to 1000 bar, -196°C to 850°C |

85% smaller than shell-and-tube models | |

Microchannel Efficiency | 0.4–4 mm channels for optimal flow |

All-Welded Construction | Leak-free, minimal maintenance |

Versatile Materials | Corrosion-resistant options |

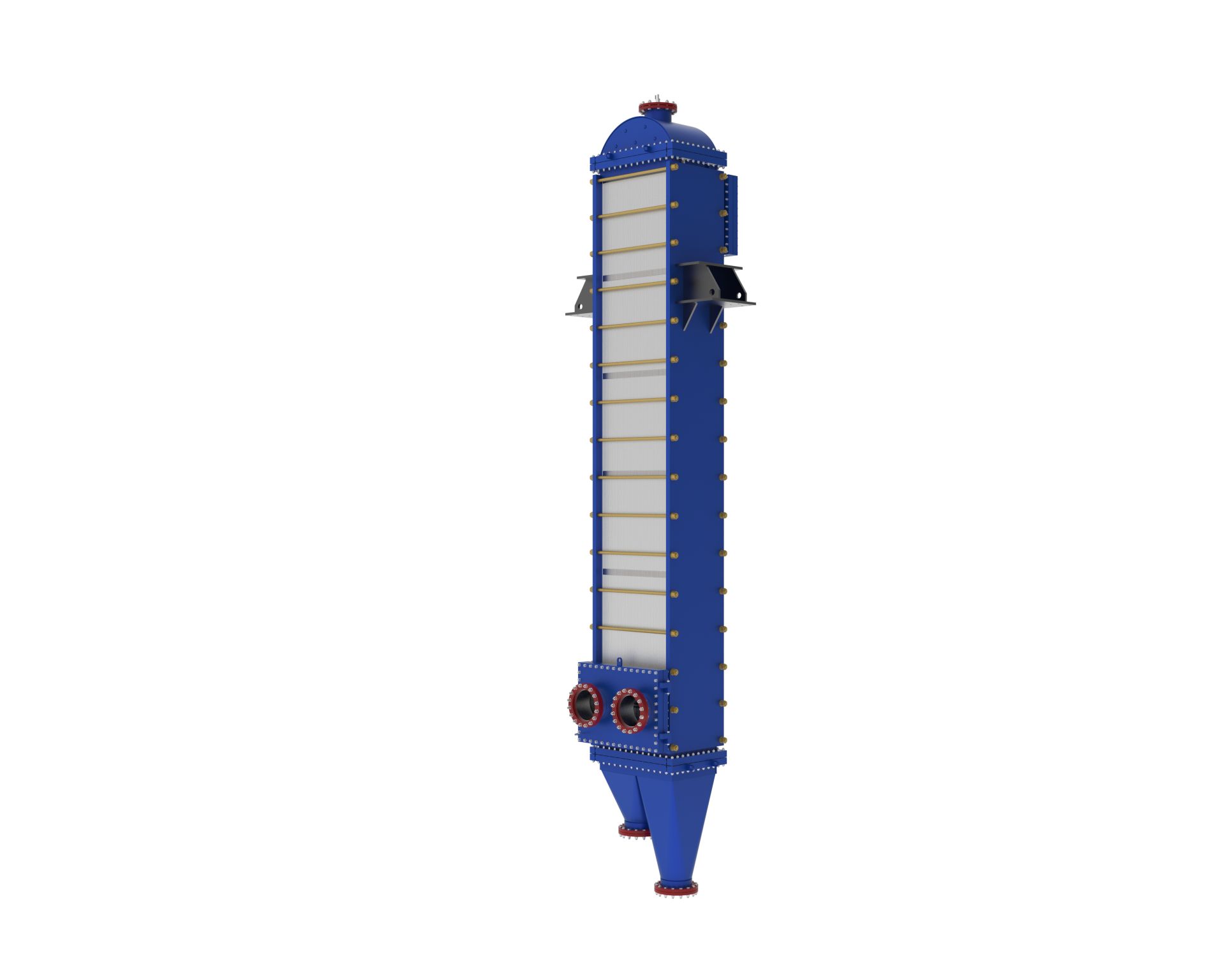

Shell-and-Tube and Air-Cooled Heat Exchangers

Shell-and-tube heat exchangers remain a top choice for large-scale commercial operations. Their tube bundles provide efficient heat transfer and durability, using materials like stainless steel or titanium. Modular designs allow for easy cleaning and maintenance, reducing downtime. These commercial heat exchangers offer customizability for specific thermal and pressure requirements, making them adaptable across industries.

·Efficient heat transfer with large surface area

·Robust construction for harsh environments

·Long operational life and cost-effectiveness

Air-cooled heat exchangers serve facilities where water is scarce, such as gas processing plants. While their efficiency rating ranges from 1.13 to 1.25 kW/ton, water-cooled models achieve higher efficiency at 0.58 to 0.79 kW/ton. Air-cooled systems provide reliable performance in challenging conditions and support operational flexibility.

Advanced Features and Smart Monitoring Systems

Modern commercial heat exchangers incorporate advanced features that enhance performance and reliability. Technologies optimize media flow and thermal efficiency, while improve plate rigidity and alignment. Offset gasket grooves simplify maintenance and maximize heat transfer area.

Innovation Type | Description |

|---|---|

Smart and Adaptive Controls | Sensors and analytics for real-time monitoring and efficiency enhancement |

IoT Integration and Predictive Maintenance | Real-time data and predictive maintenance reduce costs and downtime |

Nanotechnology in Heat Transfer Surfaces | Superior thermal conductivity and durability |

Enhanced Surface Coatings | Reduce fouling and improve efficiency |

Smart monitoring systems, such as SHPHE’s Smart Eye, provide continuous performance tracking and predictive maintenance. These systems analyze data to forecast maintenance needs, optimize operation, and support scenario visualization. Businesses benefit from reduced downtime and improved decision-making, ensuring their heat exchangers operate at peak efficiency.

Key Benefits of Heat Exchangers for Energy Efficiency

Lower Energy Consumption and Operational Costs

Commercial heat exchangers play a vital role in reducing energy consumption across a wide range of industrial applications. By recovering heat from process streams and repurposing it for preheating incoming fluids, these systems minimize the need for additional energy input. This approach leads to significant energy cost savings for businesses.

·A U-shaped heat pipe heat exchanger in a hospital achieved a heat recovery of up to 608.45 W, demonstrating substantial energy savings.

·An air handling unit with primary and secondary heat recovery units increased efficiency by 43.75%.

·A medium-sized office building in New York installed a Variable Refrigerant Flow system, resulting in a 25% decrease in energy usage.

·The use of a heat exchanger for domestic hot water preparation reduced energy consumption by about 30% compared to systems without a heat exchanger.

Regular performance assessments, such as thermographic inspections and pressure drop evaluations, help identify inefficiencies and prevent costly repairs. Balancing the load according to the heat exchanger’s specifications improves longevity and performance, which further reduces operational costs. Timely replacement of worn components sustains efficiency and minimizes energy consumption. Staff training programs also enhance proactive maintenance practices, leading to substantial cost savings.

A case study on a heat exchanger retrofit for a 13,500 SCFM catalytic oxidizer revealed significant operational cost savings. The replacement of the primary and secondary heat exchangers reduced the startup time from six hours to one hour, leading to a fuel cost reduction of approximately $230 per startup and annual savings of up to $30,000. These improvements also enhanced the destruction efficiency of the oxidizer, ensuring compliance with regulatory emission requirements.

Environmental Impact and Carbon Reduction

Heat exchangers contribute directly to environmental sustainability by lowering fuel consumption and greenhouse gas emissions. The Life Cycle Assessment of plate heat exchangers evaluates their environmental impact from raw material extraction to disposal. This comprehensive approach quantifies the carbon footprint and identifies opportunities for reducing emissions through improved design and energy efficiency.

Energy efficiency regulations for plate heat exchangers play a crucial role in minimizing energy waste and associated greenhouse gas emissions. These regulations help reduce the overall carbon footprint across various industries. Commercial heat exchangers enhance energy efficiency by optimizing energy usage and reducing the need for additional heating or cooling. They facilitate waste heat recovery, capturing energy that would otherwise be lost and reusing it in industrial processes.

1. Heat exchangers can achieve up to 40% energy cost savings.

2. They can lead to CO2 emission reductions of up to 100%.

Heat exchangers are crucial in optimizing HVAC systems, which is essential for energy conservation and reducing carbon emissions. They help in capturing and utilizing waste heat, thus playing a significant role in sustainable building operations.

Enhanced Reliability and System Control

Advanced commercial heat exchangers improve reliability and system control in modern facilities. Recent research highlights the role of advanced heat exchangers in improving the efficiency of liquid cooling solutions for electronics, indicating reliability improvements in commercial systems.

Source | Description |

|---|---|

Advanced Thermal Solutions | Advanced heat exchangers improve the efficiency of liquid cooling solutions for electronics, boosting reliability. |

True Blue AC | Retrofitting existing heat exchangers enhances energy efficiency, which is crucial for operational reliability. |

CEEE and 3-D Systems | Miniaturized air-to-refrigerant heat exchanger increased efficiency by 20% while reducing size and weight. |

Modern heat exchangers optimize thermal management and energy efficiency, which is crucial for enhancing system control in commercial applications. They allow for precise temperature adjustments by facilitating the transfer of thermal energy between fluids without direct mixing. This capability improves overall system performance, supports indoor air quality, and maintains indoor comfort.

Custom heat exchangers designed for specific industrial cooling systems ensure reliable operation and long service life. Smart monitoring systems, such as those offered by leading manufacturers, provide real-time data and predictive maintenance. These features help operators maintain optimal conditions, reduce downtime, and extend equipment lifespan.

Selecting and Implementing the Right Commercial Heat Exchanger

Factors for Choosing the Best Heat Exchanger in 2025

Selecting the optimal heat exchanger for industrial applications in 2025 requires a thorough evaluation of operational needs and sector-specific priorities. Engineers assess temperature range, pressure rating, and the ability to handle fluctuations. They measure thermal duty to confirm the unit meets process demands. Fluid properties, such as viscosity and particulates, influence the choice between plate and tubular designs. Plate heat exchangers offer superior efficiency and cost-effectiveness for clean fluids, while tubular models suit highly viscous or particulate-laden streams.

Tip: Consider fouling potential and ease of cleaning to maintain long-term efficiency and sustainability.

Industry sectors prioritize features based on their unique requirements. The following table highlights these preferences:

Industry Sector | Prioritized Features |

|---|---|

Oil Refineries | Durability, reliability, efficiency |

Petrochemical Industry | Efficient heat exchange for cooling and condensing |

Power Plants | Heat recovery, cooling applications |

Food Industry | Precise temperature control for pasteurization |

Commercial Buildings | Effective heating and cooling for indoor environments |

Engineers also factor in operating conditions, space constraints, energy efficiency, and regulatory compliance when selecting heat exchangers for industrial cooling systems and heat recovery applications.

Installation, Maintenance, and Compliance Best Practices

Proper planning during installation ensures the heat exchanger matches the size and capacity required for optimal performance. Material compatibility, such as stainless steel or copper, extends equipment life and supports sustainability goals. Seamless integration with chillers, boilers, and ductwork enhances indoor air quality and indoor comfort.

Routine maintenance, including inspections for leaks and cleaning surfaces, optimizes efficiency and extends lifespan. Early detection of abnormalities prevents failures, while tailored strategies based on operational data address trends like overheating. Proactive maintenance reduces downtime and supports reliable heat recovery in industrial cooling systems.

Compliance with 2025 standards remains essential. EPA regulations and the AIM Act mandate the transition to low-GWP refrigerants, such as R-32 and R-454B, supporting global climate commitments. Updated technician training ensures safe handling of new refrigerants and maintains regulatory alignment.

Modern commercial heat exchangers deliver energy efficiency, cost-effectiveness, and heat recovery across industries. The table below highlights key benefits:

Benefit | Description |

|---|---|

Energy Efficiency | Reduces operational expenses by reclaiming waste energy. |

Ease of Maintenance | Straightforward design with infrequent maintenance. |

Cost-Effectiveness | Long-term savings can reach 30%. |

System Integration | Modular design enables easy installation. |

Environmental Sustainability | Optimizes energy use and minimizes waste. |

Versatility | Suitable for diverse applications. |

Businesses should evaluate current systems for heat recovery opportunities and consult experts to align with sustainability goals. Investing in advanced heat exchangers supports competitiveness and sustainability in 2025.

FAQ

What role do heat exchangers play in hvac systems?

Heat exchangers transfer thermal energy between fluids in hvac systems. They improve efficiency, reduce energy costs, and support reliable temperature control for commercial buildings.

How do plate heat exchangers benefit hvac operations?

Plate heat exchangers increase heat transfer rates in hvac systems. They save space, lower maintenance needs, and help businesses achieve sustainability goals in modern hvac environments.

Why should businesses upgrade heat exchangers in their hvac systems?

Upgrading heat exchangers in hvac systems enhances energy efficiency, supports regulatory compliance, and ensures optimal performance for advanced hvac applications in commercial and industrial sectors.