What Is a Shell and Plate Heat Exchanger?

What Is a Shell and Plate Heat Exchanger?

Industries in 2025 achieve higher efficiency by adopting the shell and plate heat exchanger. This technology reduces energy consumption and improves operational performance.

Exploring the Efficiency of Shell and Plate Heat Exchangers in Industrial Applications reveals why manufacturers select these designs for reliability and cost savings.

Basic Design and Function

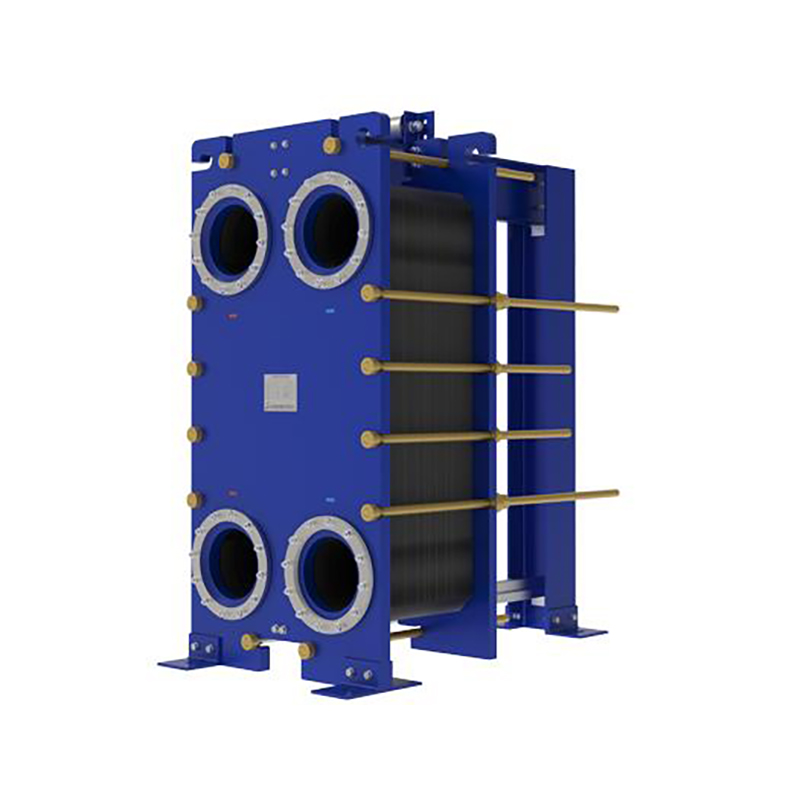

A shell and plate heat exchanger uses a series of thin, corrugated plates stacked together inside a cylindrical shell. The plates create multiple channels for fluids to flow. One fluid moves between the plates, while the other flows over the plates within the shell. This design maximizes the surface area for heat transfer. The compact structure allows for efficient thermal exchange in a small footprint

Key features include:

·High pressure and temperature resistance

·Flexible design for different flow arrangements

·Easy access for cleaning and inspection

How Shell and Plate Heat Exchangers Work in Industrial Settings

In industrial environments, a shell and plate heat exchanger transfers heat between two process streams. For example, hot oil may flow through the plates, while cooling water circulates in the shell. The temperature difference between the fluids drives heat transfer. Operators can adjust flow rates or temperatures to meet process requirements.

Industries benefit from:

·Rapid heat transfer rates

·Minimal risk of fluid mixing

·Reliable operation under demanding conditions

A shell and plate heat exchanger often replaces older models because it offers better efficiency and lower maintenance needs. Many facilities choose this technology to improve energy use and reduce downtime.

Efficiency Advantages of Shell and Plate Heat Exchangers

Thermal Performance Comparison with Other Types

Shell and plate heat exchangers deliver superior thermal performance compared to traditional shell and tube or gasketed plate models. The unique plate arrangement creates high turbulence, which increases heat transfer rates. This design allows for efficient temperature control, even when handling fluids with different properties.

Engineers often compare heat exchangers using the overall heat transfer coefficient. Shell and plate heat exchangers usually achieve higher coefficients due to their compact plate geometry. The table below highlights key differences:

| Heat Exchanger Type | Heat Transfer Coefficient | Footprint Size | Pressure Resistance |

|---|---|---|---|

| Shell and Tube | Moderate | Large | High |

| Gasketed Plate | High | Small | Moderate |

| Shell and Plate | Very High | Compact | Very High |

Energy Savings and Cost Reduction

Industrial facilities seek ways to lower energy consumption and reduce costs. Shell and plate heat exchangers help achieve these goals by maximizing heat recovery and minimizing thermal losses. Their efficient design reduces the amount of energy needed to reach target temperatures.

Key benefits include:

·Lower utility bills due to improved heat transfer

·Reduced fuel or electricity consumption

·Shorter process times, which increase productivity

Many companies report a rapid return on investment after installing a shell and plate heat exchanger. The savings on energy and maintenance often offset the initial purchase cost within a few years.

Maintenance and Reliability Benefits

Maintenance teams value equipment that operates reliably and requires minimal intervention. Shell and plate heat exchangers feature a robust structure that resists fouling and corrosion. The plate stack can be easily accessed for inspection or cleaning, which reduces downtime.

Common reliability advantages:

·Fewer leak points compared to gasketed plate models

·High resistance to pressure and temperature fluctuations

·Long service life with consistent performance

Shell and plate heat exchangers support continuous operation in demanding industrial environments. Their durability and ease of maintenance make them a preferred choice for many sectors.

Versatility of Shell and Plate Heat Exchangers Across Industries

Chemical Processing Applications

Chemical plants require precise temperature control and resistance to aggressive fluids. Engineers select shell and plate heat exchangers for their ability to handle corrosive chemicals and high pressures. The compact design fits into tight spaces, while the robust plates resist fouling. Operators can easily clean the units, which helps maintain product purity.

Oil and Gas Industry Uses

The oil and gas sector demands equipment that withstands extreme conditions. Shell and plate heat exchangers operate reliably with high-pressure gases and viscous oils. They support processes such as gas dehydration, crude oil heating, and cooling of refinery streams. Their durability reduces unplanned shutdowns and maintenance costs.

Food and Beverage Processing

Food and beverage manufacturers value hygiene and energy efficiency. The smooth plate surfaces of a shell and plate heat exchanger prevent contamination and allow for easy cleaning. These units help pasteurize liquids, cool dairy products, and recover heat from waste streams. The design supports strict sanitary standards.

Power Generation Sector

Power plants use shell and plate heat exchangers to manage steam and cooling water. The equipment handles rapid temperature changes and high pressures. Operators use them in turbine cooling, boiler feedwater heating, and waste heat recovery. The compact size saves valuable floor space in crowded facilities.

Pharmaceutical Manufacturing

Pharmaceutical production requires strict temperature control and cleanliness. Shell and plate heat exchangers provide sterile heat transfer for sensitive ingredients. The easy-to-clean plates reduce the risk of cross-contamination. Manufacturers rely on these exchangers for batch heating, cooling, and solvent recovery.

Innovations and Trends for Shell and Plate Heat Exchangers in 2025

Advanced Materials and Manufacturing Techniques

Engineers now use advanced alloys and composite materials to build heat exchangers. These materials resist corrosion and handle higher pressures. Manufacturers apply precision welding and laser cutting to create tighter seals and more efficient plate patterns. This approach increases the lifespan of each unit and improves heat transfer rates.

Smart Monitoring and Automation Integration

Modern facilities install sensors on every shell and plate heat exchanger. These sensors track temperature, pressure, and flow in real time. Operators receive instant alerts if performance drops. Automated controls adjust settings to keep processes stable. This technology reduces manual checks and helps prevent costly downtime.

Sustainability and Environmental Impact

Companies focus on reducing their carbon footprint. They choose heat exchangers that recover more waste heat and use less energy. Many designs now support eco-friendly refrigerants and fluids. This shift helps industries meet stricter environmental regulations and lower operating costs.

Digital System Integration

Digital platforms connect heat exchangers to plant-wide control systems. Operators view performance data on dashboards and analyze trends over time. This integration supports predictive maintenance and process optimization.

Key benefits include:

·Faster troubleshooting

·Improved energy management

·Better decision-making

Why Shell and Plate Heat Exchangers Are the Preferred Choice

Summary of Efficiency and Performance Benefits

Industrial engineers recognize the shell and plate heat exchanger for its outstanding efficiency. The design maximizes heat transfer while minimizing energy loss. Facilities report faster temperature changes and improved process control. Operators experience fewer interruptions because the equipment resists fouling and corrosion.

| Feature | Shell and Plate Heat Exchanger | Conventional Models |

|---|---|---|

| Heat Transfer Rate | High | Moderate |

| Maintenance Frequency | Low | High |

| Space Requirement | Small | Large |

Long-Term Value for Industrial Operations

Companies invest in shell and plate heat exchangers to achieve long-term savings. The robust construction extends service life and reduces replacement costs. Maintenance teams spend less time on repairs, which lowers labor expenses.

·Lower energy bills over time

·Fewer shutdowns for cleaning

·Consistent performance in demanding environments

Decision-makers see reliable operation as a key advantage. The equipment supports continuous production and helps facilities meet sustainability goals.

Shell and plate heat exchangers set the standard for industrial efficiency in 2025.

·Industries gain energy savings, reliability, and long-term value.

·Modern designs support sustainability and digital integration.

Experts expect these exchangers to drive innovation and performance across industrial applications in the coming years.

FAQ

What makes shell and plate heat exchangers suitable for high-pressure applications?

Engineers select these exchangers for high-pressure tasks because the welded plate design resists leaks and handles extreme operating conditions.

Note: The robust construction ensures reliable performance in demanding environments.

How often should maintenance teams inspect shell and plate heat exchangers?

Most facilities schedule inspections every six to twelve months. Regular checks help maintain efficiency and extend equipment lifespan.

Can shell and plate heat exchangers handle corrosive fluids?

Yes. Manufacturers use corrosion-resistant materials, such as stainless steel or titanium, to ensure safe operation with aggressive chemicals.

·Stainless steel suits most chemicals.

·Titanium handles highly corrosive fluids.