Exploring the Function of Plate Heat Exchanger Gaskets in 2025

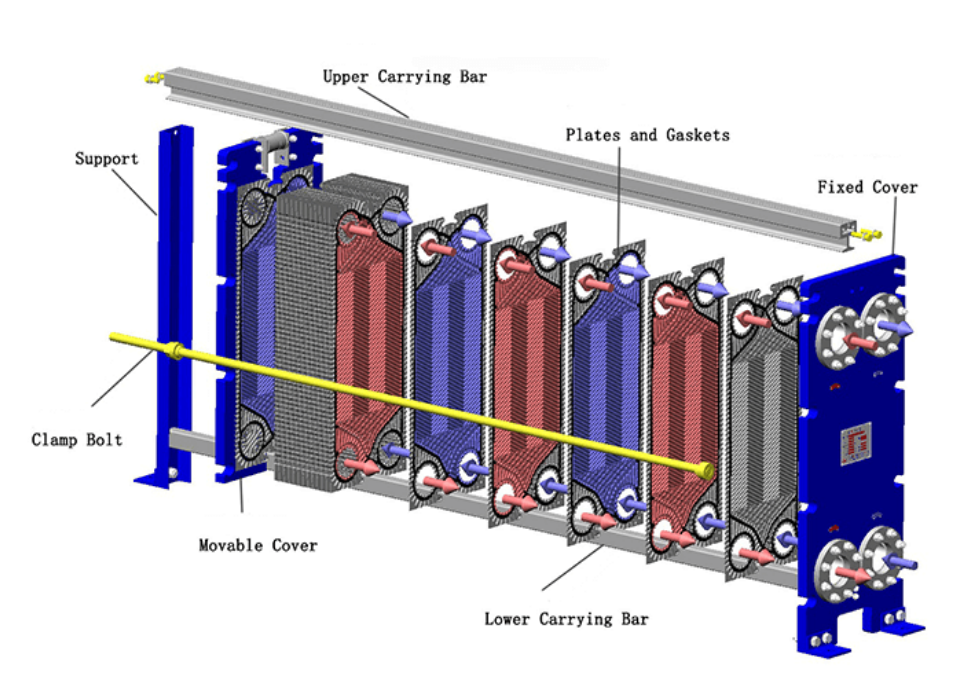

Plate Heat Exchanger Gaskets: How They Work

Sealing and Preventing Leaks

Plate heat exchanger gaskets create a tight seal between metal plates. This seal prevents fluids from escaping the system. Engineers design these gaskets to withstand high temperatures and aggressive chemicals. In 2025, industries demand even greater reliability from these components.

Reliable sealing protects equipment and reduces downtime.Operators inspect gaskets regularly to ensure they remain intact. When a gasket fails, leaks can cause contamination or loss of product. Manufacturers use advanced materials to improve sealing performance and extend service life.

Maintaining Pressure and Flow Control

Plate heat exchanger gaskets help maintain stable pressure within the system. Each gasket directs fluids along specific channels. This design ensures that hot and cold fluids do not mix.

·Consistent pressure supports efficient heat transfer.

·Proper flow control prevents system overloads.

Technicians monitor pressure levels to detect early signs of gasket wear. In modern facilities, sensors provide real-time feedback on pressure and flow. These innovations allow operators to respond quickly to any changes.

| Function | Impact on System | Monitoring Method |

|---|---|---|

| Pressure Control | Prevents surges | Sensors, gauges |

| Flow Direction | Avoids cross-contamination | Visual inspection |

Enhancing Heat Transfer Efficiency

Plate heat exchanger gaskets play a key role in maximizing heat transfer. They keep fluids separated while allowing plates to exchange thermal energy.

Efficient gaskets reduce energy consumption and operating costs.Engineers select gasket designs that minimize thermal resistance. In 2025, new materials and shapes improve contact between plates. These advances boost overall system efficiency.Operators choose gaskets based on the specific needs of each application. Proper installation and maintenance ensure that heat exchangers perform at their best.

Plate Heat Exchanger Gaskets: Materials and Design in 2025

Common Materials Used

Manufacturers select materials for plate heat exchanger gaskets based on durability and resistance to harsh environments. In 2025, the most common materials include:

·Nitrile rubber (NBR): Offers strong oil and water resistance.

·Ethylene propylene diene monomer (EPDM): Handles high temperatures and chemicals.

·Fluoroelastomer (FKM): Resists aggressive chemicals and extreme heat.

·Silicone: Provides flexibility and stability in food and pharmaceutical applications.

These materials help gaskets maintain their shape and function under pressure.

Material Selection for Industrial Demands

Engineers match gasket materials to the specific needs of each industry. For example, food processing plants require materials that meet strict hygiene standards. Chemical plants need gaskets that withstand corrosive fluids. Operators consider factors such as:

| Industry | Key Requirement | Preferred Material |

|---|---|---|

| Food & Beverage | Hygiene, flexibility | Silicone, EPDM |

| Chemical | Chemical resistance | FKM, EPDM |

| Oil & Gas | Oil resistance | NBR, FKM |

Technological Advances in Gasket Design

In 2025, new technologies improve gasket performance. Manufacturers use computer-aided design (CAD) to create precise gasket shapes. Advanced manufacturing methods, such as 3D printing, allow for custom designs that fit unique systems. Some gaskets now feature embedded sensors that monitor temperature and pressure in real time. These innovations help operators detect problems early and maintain efficient operation.

Plate Heat Exchanger Gaskets: Applications and Benefits

Key Industrial Uses

Plate heat exchanger gaskets support many industries. Chemical plants use these gaskets to separate hazardous fluids. Food and beverage factories rely on them to maintain hygiene and prevent contamination. Power generation facilities depend on plate heat exchanger gaskets to regulate temperature and improve energy efficiency. Water treatment plants also benefit from their ability to handle corrosive liquids.Operators in these sectors choose gaskets based on the demands of each process.

Efficiency, Maintenance, and Safety Benefits

Plate heat exchanger gaskets increase system efficiency by reducing energy loss. They help maintain optimal flow and temperature control. Regular inspection and replacement of gaskets lower the risk of leaks and equipment failure.

·Improved safety protects workers and the environment.

·Lower maintenance costs result from durable gasket materials.

Technicians use monitoring tools to track gasket performance. Quick detection of wear or damage prevents costly downtime.

| Benefit | Description |

|---|---|

| Efficiency | Reduces energy consumption |

| Maintenance | Extends equipment lifespan |

| Safety | Prevents leaks and contamination |

Innovations and Future Trends

In 2025, manufacturers introduce smart gaskets with embedded sensors. These sensors provide real-time data on temperature and pressure. Engineers use this information to optimize system performance.

Future trends include eco-friendly materials and advanced manufacturing techniques.

Researchers develop gaskets that last longer and resist more chemicals. The industry expects further improvements in automation and predictive maintenance.

·Plate heat exchanger gaskets support industrial performance by ensuring reliable operation.

·Recent advancements improve efficiency and safety in 2025.

·Proper selection and routine maintenance extend equipment lifespan.

Smart gasket technology helps operators detect issues early and optimize system reliability.

FAQ

What causes plate heat exchanger gaskets to fail?

Gasket failure often results from chemical attack, extreme temperatures, or improper installation. Regular inspection helps identify early signs of wear or damage.

How often should operators replace gaskets?

Replacement intervals depend on operating conditions and material type. Most facilities schedule inspections every 6–12 months.

Can smart gaskets reduce maintenance costs?

Yes. Smart gaskets with embedded sensors provide real-time data. Operators use this information to schedule maintenance only when needed, saving time and money. 🛠️