How Plate Heat Exchanger Catalogues Empower Engineers in Modern Facilities

Plate Heat Exchanger Catalogue: Features and Engineering Value

Comprehensive Data and Key Specifications

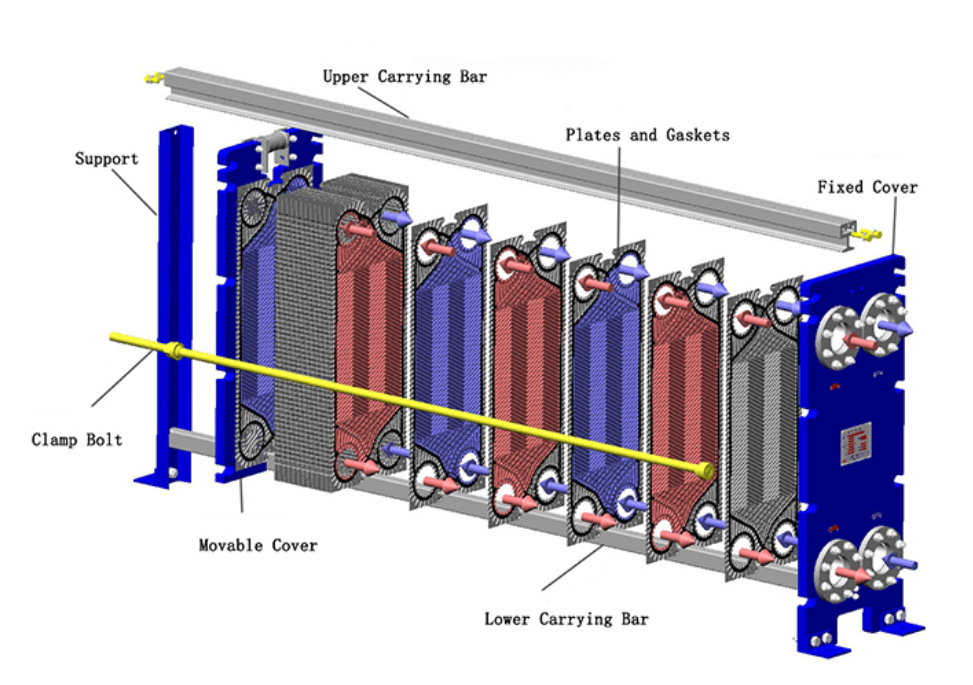

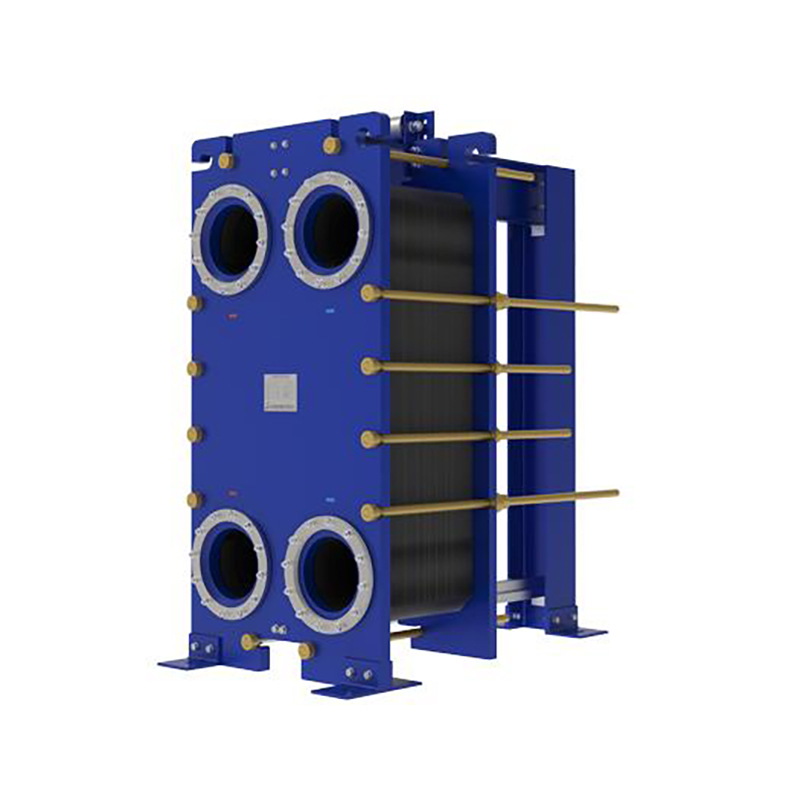

A plate heat exchanger catalogue provides engineers with detailed technical data. Each entry lists essential specifications such as plate material, maximum pressure, temperature limits, and flow rates. Engineers can quickly compare these values to ensure compatibility with their facility’s requirements.

Many catalogues also include performance curves and pressure drop charts. These resources allow engineers to predict how a unit will perform under different operating conditions. With this information, teams can make informed decisions that improve system efficiency and reliability.

Types and Designs for Diverse Applications

Modern facilities require a range of heat exchanger types. A plate heat exchanger catalogue typically covers several designs, including:

·Gasketed plate heat exchangers

·Brazed plate heat exchangers

·Welded plate heat exchangers

·Semi-welded plate heat exchangers

Each type serves specific applications, from HVAC systems to chemical processing. The catalogue describes the advantages and limitations of each design. Engineers use this information to match the right model to their project’s needs.

| Type | Best Use Case | Key Feature |

|---|---|---|

| Gasketed | HVAC, food industry | Easy maintenance |

| Brazed | Refrigeration, oil | Compact size |

| Welded | Aggressive fluids | High durability |

| Semi-welded | Ammonia systems | Leak resistance |

Plate Heat Exchanger Catalogue: Selection, Optimization, and Real-World Impact

Specification, Sizing, and Model Comparison

Engineers use a plate heat exchanger catalogue to compare models based on technical specifications. They examine plate area, number of passes, and connection sizes. These details help them select equipment that matches the required heat transfer rate and available space.

A typical selection process involves three steps:

Identify the required duty and operating conditions.

Review catalogue tables for compatible models.

Compare sizing options to optimize performance and footprint.

A well-organized plate heat exchanger catalogue presents side-by-side comparisons. This format allows engineers to evaluate multiple units quickly. They can spot differences in capacity, dimensions, and material options. This approach reduces the risk of choosing an undersized or oversized unit.

Customization for Application Matching

Modern facilities demand tailored solutions. Engineers use the catalogue to customize plate heat exchangers for specific applications. They select plate patterns, gasket materials, and frame types that suit process fluids and temperature ranges.

Customization options include:

·Plate corrugation styles for enhanced turbulence.

·Gasket compounds for chemical compatibility.

·Modular frame designs for easy expansion.

A catalogue often provides guidance on matching these features to industry requirements. For example, food processing plants need sanitary designs, while chemical plants require corrosion-resistant materials. Engineers consult the catalogue to ensure every component meets safety and regulatory standards.

Reliability, Maintenance, and Cost Analysis

Reliability remains a top priority in facility operations. Engineers assess maintenance requirements and lifecycle costs using catalogue data. They review recommended cleaning intervals, gasket replacement schedules, and spare part availability.

A comparison table in the catalogue might look like this:

| Model | Maintenance Interval | Estimated Lifespan | Spare Parts Availability |

|---|---|---|---|

| HX-100 | 12 months | 10 years | High |

| HX-200 | 18 months | 12 years | Medium |

| HX-300 | 24 months | 15 years | High |

Engineers use this information to forecast operational expenses and downtime. They select models that balance upfront investment with long-term reliability. The plate heat exchanger catalogue empowers teams to make informed decisions that support both budget and performance goals.

Engineers who leverage catalogue insights can reduce maintenance costs and extend equipment life. 🛠️

·Engineers depend on reliable tools to achieve optimal performance and cost savings.

·Integrating a plate heat exchanger catalogue into daily workflows supports better decisions.

·Teams improve facility outcomes when they maximize efficiency and reliability through informed equipment selection.

FAQ

What information does a plate heat exchanger catalogue provide?

A catalogue lists technical specifications, performance data, and model options. Engineers use this information to select equipment that matches facility requirements.

How do engineers use catalogues for equipment sizing?

Engineers compare plate area, flow rates, and pressure drop charts. This process helps them choose the correct size for optimal heat transfer and efficiency.

| Parameter | Purpose |

|---|---|

| Plate Area | Heat Transfer |

| Flow Rate | System Capacity |

| Pressure Drop | Efficiency |

Can catalogues help reduce maintenance costs?

Catalogues provide maintenance intervals, spare part availability, and estimated lifespan. Engineers use this data to plan service schedules and minimize downtime.

·Regular review of catalogue recommendations extends equipment life.

·Scheduled maintenance reduces unexpected failures.