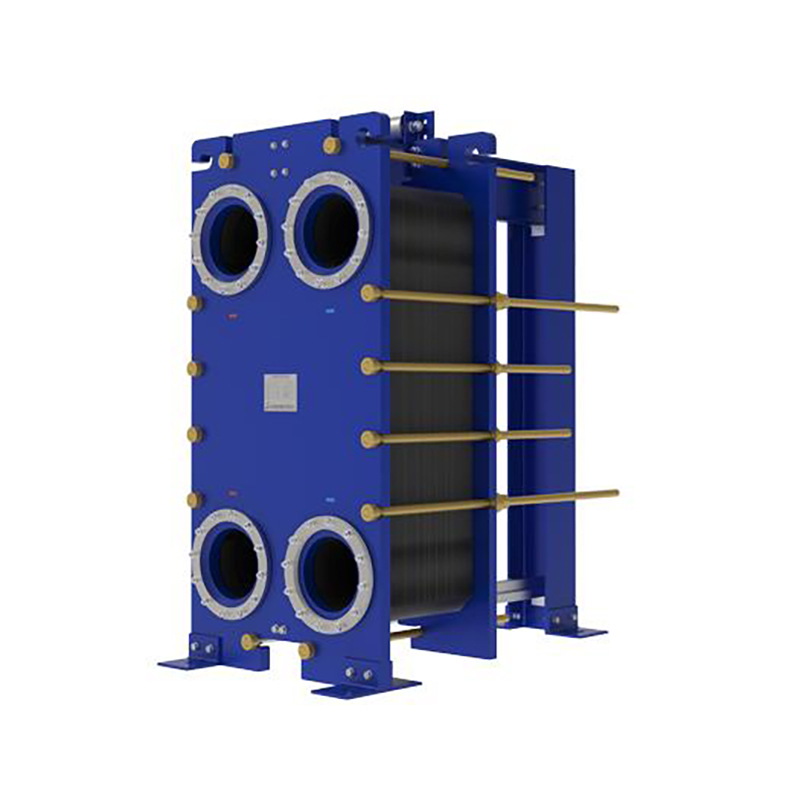

Boosting Industrial Efficiency with Gasketed Plate Heat Exchangers

Achieve Superior Thermal Performance

The primary function of any heat exchanger is efficient thermal management. A gasketed plate and frame heat exchanger excels in this area by design, delivering performance that traditional shell-and-tube units often cannot match. This superior capability stems from two key engineering features.

Maximize Heat Transfer with Corrugated Plates

The core of the unit is its series of thin, corrugated metal plates. These plates are pressed with specialized patterns that serve a dual purpose. First, they create a large surface area for heat exchange within a very small volume. Second, and more importantly, these patterns induce highly turbulent flow even at low fluid velocities. This turbulence is critical for performance.

·It breaks up the fluid's boundary layer.

·It forces more of the process media to contact the plate surface.

·It dramatically increases the heat transfer coefficient.

This engineered flow path ensures that the maximum amount of thermal energy moves from the hot fluid to the cold fluid.

Attain Close Temperature Approaches

High efficiency allows these units to achieve a close temperature approach. This term refers to the small temperature difference between the hot fluid leaving the unit and the cold fluid entering it.

What does this mean for your process?

A close temperature approach, often as tight as 1°C (2°F), signifies maximum heat recovery. This directly translates to reduced energy consumption and lower utility costs for heating or cooling operations. 🌡️

This level of performance is a direct result of the turbulent flow and high heat transfer rates created by the corrugated plates. It allows facilities to optimize energy use and gain precise control over process temperatures.

Realize Significant Cost and Space Savings

Beyond thermal performance, a gasketed plate and frame heat exchanger provides substantial economic and logistical advantages. Its intelligent engineering directly impacts a facility's budget and physical layout, delivering savings that accumulate over the unit's lifespan. These benefits begin with the initial purchase and continue through installation and operation.

Reduce Footprint with a Compact Design

Industrial floor space is a valuable asset. Plate heat exchangers offer a significant advantage with their compact construction. The high-density plate pack achieves the same or greater thermal duty as a traditional shell-and-tube unit in a much smaller package.

A plate heat exchanger can occupy as little as 20-50% of the floor space required by a shell-and-tube unit with an equivalent capacity. This smaller footprint frees up critical area for other process equipment or future expansion. 📏

This space efficiency is especially beneficial for retrofitting existing plants or designing new facilities where maximizing operational space is a primary goal.

Lower Capital and Installation Expenses

The compact and lightweight nature of the design translates directly into lower upfront costs. The unit requires less raw material to build, reducing its initial purchase price. Furthermore, installation becomes simpler and more affordable.

·Reduced Structural Needs: The lighter weight often eliminates the need for costly, heavy-duty foundations or structural steel supports.

·Simplified Logistics: Handling and positioning the unit requires less heavy lifting equipment, such as large cranes. 🏗️

·Faster Installation: The straightforward design and smaller size reduce the labor hours needed for placement and connection, accelerating project timelines.

These factors combine to lower the total installed cost, making the technology an economically sound choice from day one.

How a Gasketed Plate and Frame Heat Exchanger Boosts Flexibility

Industrial processes rarely remain static. A gasketed plate and frame heat exchanger offers exceptional operational flexibility to meet these evolving demands. Its modular design and wide material selection allow facilities to adapt quickly and cost-effectively. This adaptability is a key advantage over fixed-capacity heat exchangers.

Adapt Capacity to Changing Process Needs

The core design of the unit is inherently modular. The heat transfer surface area is determined by the number of plates installed within the frame. This allows operators to modify the unit's thermal capacity with minimal effort.

Need more capacity? Simply add more plates to the existing frame.Process requirements reduced? Remove plates to optimize performance and pressure drop. ⚙️

This scalability means a facility can:

·Avoid the high initial cost of an oversized unit.

·Easily adjust to seasonal variations in production.

·Expand operations without replacing the entire heat exchanger.

The frame is often designed to accommodate future expansion, making it a future-proof investment.

Ensure Compatibility with Diverse Materials

Different industrial applications involve a wide range of process fluids, some of which can be corrosive or require hygienic handling. The plate and frame design addresses this challenge by offering a broad selection of materials for both plates and gaskets.

| Component | Common Materials |

|---|---|

| Plates | Stainless Steel, Titanium, Nickel Alloys |

| Gaskets | NBR (Nitrile), EPDM, FKM (Viton™) |

This material versatility ensures the heat exchanger can be precisely configured for its specific duty. It can safely handle everything from potable water and food products to aggressive chemicals and seawater. This customization ensures long service life and prevents process contamination.

Simplify Maintenance and Minimize Downtime

Efficient maintenance procedures are critical for maximizing plant productivity. A gasketed plate and frame heat exchanger is engineered specifically to reduce service time and complexity. This intelligent design directly minimizes costly operational downtime, keeping processes running smoothly.

Gain Full Access for Cleaning and Inspection

The unit’s frame allows maintenance teams to open the plate pack completely. Technicians simply loosen the tie bolts and slide the movable pressure plate away from the fixed frame. This action provides immediate visual and physical access to every individual plate surface.This level of accessibility is a major advantage. It allows for thorough inspection and effective cleaning, which is often difficult or impossible with shell-and-tube designs. 🧼

Crews can easily identify and remove any fouling or scaling. This ensures the heat exchanger is restored to its peak thermal performance after each service, eliminating the guesswork involved in cleaning enclosed systems.

Enable Fast, On-Site Serviceability

The design promotes rapid, in-place maintenance. Most service tasks, such as gasket replacement or plate cleaning, can be performed without disconnecting the unit’s main piping. This feature saves significant labor and time. A single technician can often complete the entire service using standard tools.

Key service benefits include:

·Simple Gasket Replacement: Old gaskets are easily removed from their grooves and replaced with new ones.

·Individual Plate Access: Damaged or fouled plates can be serviced or replaced one by one.

·Reduced Labor: The process does not require heavy lifting equipment or specialized contractors. 🔧

This straightforward serviceability allows facilities to manage maintenance in-house, shortening turnaround times and keeping critical operations online.

Enhance Operational Reliability and Uptime

A gasketed plate heat exchanger's engineering directly contributes to greater operational reliability and extended uptime. Its design incorporates specific features that combat common causes of failure and service interruptions, such as fouling and leaks. This focus on durability ensures the unit performs consistently day after day.

Minimize Fouling with Turbulent Flow

The corrugated plate design actively resists fouling. It creates a highly turbulent flow across the heat transfer surfaces, even at low velocities. This turbulence generates a powerful scouring effect. The scouring action prevents suspended solids from settling and building up on the plates.

This self-cleaning characteristic maintains high thermal efficiency for longer periods. It significantly reduces the need for frequent maintenance shutdowns. 🛡️

The result is more consistent performance and greater process availability, keeping your operations running at peak capacity with less intervention.

Prevent Leaks with High-Integrity Sealing

The gasket system provides a robust barrier against leaks and cross-contamination. Each plate features a precisely engineered gasket groove that secures the elastomer seal. When the plate pack is compressed, this system creates a highly reliable seal.

Key features of this sealing system include:

·Double Seal Design: A special arrangement prevents the two different fluids from ever mixing.

·Leak Detection Path: It directs any potential leak to the exterior of the unit for immediate visual detection.

·Secure Gasket Grooves: The design holds gaskets firmly in place, even during pressure fluctuations.

This advanced sealing integrity protects both the process fluids and the equipment, ensuring safe and continuous operation.

Gasketed plate heat exchangers are the superior choice for modern industrial applications. Their combined advantages deliver better process control, lower energy bills, and a reduced total cost of ownership. Contact our experts to assess how a GPHE can optimize specific thermal management needs. 📞

FAQ

What limits the operating temperature of a GPHE?

The gasket material determines the maximum operating temperature. Different elastomers like NBR, EPDM, and FKM have specific temperature ratings that dictate the unit's safe operational range.

How does a GPHE compare to a welded unit?

A gasketed design offers distinct advantages over a welded one.

·It allows complete access for maintenance and cleaning.

·It provides the flexibility to add or remove plates.

·It simplifies on-site service and gasket replacement.

Can these units handle high-pressure applications?

Yes, they can manage high pressures. The frame and tie bolts compress the plate pack, creating a robust structure capable of handling demanding industrial process pressures. ⚙️