Are Fully Welded Plate Heat Exchangers Worth the Investment

Understanding the Core Technology of a Fully Welded Plate Heat Exchanger

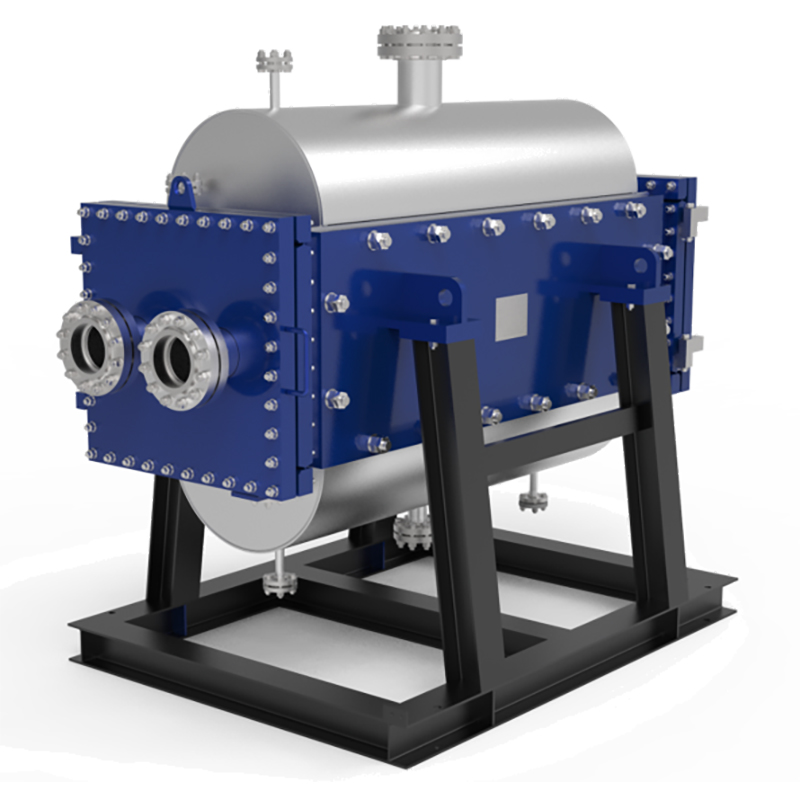

The performance of a fully welded plate heat exchanger stems from its unique and robust construction. Three core design elements work together to deliver superior efficiency and reliability in demanding industrial environments.

The Gasket-Free Welded Design

Traditional heat exchangers often rely on gaskets to seal the plates. These gaskets can degrade over time, causing leaks and requiring maintenance. This model eliminates that weak point entirely. Engineers laser weld the stainless steel or special alloy plates together, creating a permanent, hermetic seal.

This welded plate pack provides several key advantages:

·It prevents leaks between fluid channels.

·It withstands extreme pressures and temperatures that would destroy gaskets.

·It ensures safe containment of aggressive or hazardous fluids.

How Corrugated Plates Maximize Efficiency

The plates inside the unit are not flat. They feature a specially engineered, corrugated pattern. This design forces the fluids to flow turbulently as they move through the heat exchanger. This turbulence dramatically increases the rate of heat transfer between the two fluids. The corrugated pattern also increases the total surface area available for heat exchange within a given volume, boosting overall thermal performance.

Compact Footprint by Design

High efficiency directly translates to a smaller size. Because the corrugated plates transfer heat so effectively, less surface area is needed to achieve the desired thermal duty compared to older technologies like shell and tube exchangers.

Design Tip: This compact and lightweight design reduces structural support requirements and frees up valuable floor space in a plant. It makes installation simpler and less expensive, especially in crowded mechanical rooms or offshore platforms.

Why the Investment Pays Off: Key Financial Advantages

While the initial purchase price of a fully welded unit is higher than its gasketed counterparts, a total cost of ownership analysis reveals significant long-term financial benefits. These advantages stem directly from its superior design, efficiency, and reliability, making it a strategic investment for savvy operators.

Lower Lifetime Operational Costs

Operational expenditures (OPEX) often outweigh the initial capital cost of equipment over its service life. The robust, gasket-free design of a fully welded plate heat exchanger directly targets and reduces these recurring expenses.

·Eliminates Gasket Replacement: Traditional exchangers require periodic gasket replacement. This process involves costs for parts, specialized labor, and planned downtime. The welded design has no gaskets to fail or replace, completely removing this maintenance budget item.

·Minimizes Unplanned Downtime: Gasket failures are a common cause of unexpected shutdowns and production losses. The hermetic seal of a welded unit provides exceptional reliability, safeguarding plant uptime and revenue generation.

·Reduces Maintenance Labor: With no gaskets to inspect, tighten, or replace, maintenance teams can dedicate their time to other critical plant activities. This optimization of labor resources contributes to a leaner, more efficient operation.

Maximized Energy Efficiency

Energy is one of the largest operational costs in any thermal process. The superior thermal performance of welded plate technology translates directly into substantial energy savings. The corrugated plates create high turbulence, which enhances the heat transfer rate.

The Financial Impact of Efficiency: A higher heat transfer coefficient means the unit can achieve the same heating or cooling duty using less energy. This could mean lower fuel consumption for a boiler, reduced electricity usage for a chiller, or less steam required from a central plant. These savings accumulate 24/7, delivering a continuous return on investment.

A more efficient heat exchanger allows for tighter process control. This stability can improve final product quality and reduce waste, adding another layer of financial benefit.

| Feature | Gasketed Plate Exchanger | Shell and Tube Exchanger | Fully Welded Plate Exchanger |

|---|---|---|---|

| Energy Use | Good | Moderate | Excellent (Lowest) |

| Approach Temp. | Very Good | Moderate | Excellent |

| Result | Efficient Operation | Higher Energy Bills | Maximum Energy Savings 💰 |

Reduced Installation and Structural Costs

The financial advantages begin even before the unit is operational. The compact and lightweight nature of the design significantly lowers project and installation expenses compared to bulkier technologies like shell and tube exchangers.

Key installation savings include:

·Smaller Footprint: The unit requires less valuable plant floor space. In new construction, this can reduce the overall size and cost of the building itself.

·Lower Structural Load: Its lighter weight reduces the need for expensive, heavy-duty foundations, structural steel supports, and overhead rigging.

·Simplified Logistics: A smaller, lighter unit is easier and cheaper to transport to the site and maneuver into its final position, often requiring smaller cranes and less complex installation procedures.

These factors shorten the project timeline and reduce capital expenditure, making the overall investment more attractive from day one.

Performance and Reliability Benefits for Your Application

Beyond financial returns, the operational advantages of a fully welded unit directly enhance plant performance and reliability. Its design delivers tangible benefits in the most challenging industrial settings.

Superior Durability in Tough Conditions

Industrial processes often involve intense thermal and pressure cycling. A fully welded plate heat exchanger excels in these environments. The welded construction creates a solid, durable core that resists fatigue from constant expansion and contraction. This robustness prevents mechanical stress failures common in gasketed designs. The unit maintains its structural integrity under continuous operational strain, ensuring a long and reliable service life in harsh applications like oil refining, gas processing, and chemical production.

Enhanced Safety with Hazardous Fluids

Safety is the highest priority when a process involves aggressive or hazardous materials. The unit’s gasket-free design provides superior containment for dangerous fluids. It creates a hermetically sealed system that virtually eliminates the risk of external leaks.

Critical Containment: This leak-proof integrity is essential for handling toxic, flammable, or corrosive substances. It protects personnel from exposure, prevents environmental contamination, and safeguards expensive process fluids.

Consistent and Sustained Thermal Performance

The performance of some heat exchangers can degrade over time. The rigid, welded plate pack of this model ensures consistent and predictable thermal efficiency throughout its lifespan. The plates are locked in place, preventing the shifting or deformation that can disrupt fluid flow in other designs. This structural stability guarantees that the heat transfer rate remains high and stable. Operators can rely on the unit to deliver its specified duty year after year without unexpected performance drops.

When Is the Investment Justified? Ideal Scenarios

A fully welded plate heat exchanger is a specialized solution. Its value becomes clear in specific operational contexts where standard equipment falls short. The decision to invest is justified when the long-term benefits of reliability, safety, and efficiency outweigh a higher initial cost. Certain scenarios make this choice not just beneficial, but essential.

High-Pressure or Extreme-Temperature Processes

Standard gasketed heat exchangers have clear operational limits. High pressures can cause gasket failure, while extreme temperatures can make them brittle or degrade them. A welded design thrives in these conditions.

·Pressure Resistance: The welded seams create a monolithic core. This structure can withstand pressures far exceeding the limits of elastomeric gaskets, making it ideal for applications like gas compression or high-pressure hydraulic systems.

·Thermal Resilience: These units operate effectively in services with extreme temperatures, both hot and cold. They handle cryogenic applications (like LNG processing) and high-temperature duties (like thermal oil systems) without the risk of seal failure from thermal stress.

·Cycling Duties: Processes with frequent temperature and pressure swings cause fatigue in gasketed joints. The robust, welded construction resists this mechanical stress, ensuring a long service life in demanding cycling applications.

Handling Aggressive and Corrosive Fluids

Safety and containment are paramount when working with hazardous materials. The primary advantage here is the elimination of potential leak points.

Zero-Leak Tolerance: In the chemical, refining, and pharmaceutical industries, even a minor leak of a toxic or corrosive fluid can have severe consequences for personnel safety and the environment. The hermetically sealed plate pack of a welded unit provides the highest level of fluid containment, making it the default choice for handling substances like ammonia, acids, or solvents.

The unit's construction from high-grade alloys, such as titanium or Hastelloy, also provides superior resistance to corrosion from the process fluids themselves. This ensures both internal and external integrity over the long term.

When Minimizing Downtime Is Critical

For many industrial operations, uptime is directly linked to revenue. Unplanned downtime is not just an inconvenience; it is a significant financial loss. The investment in a welded unit is easily justified in any process where continuous operation is a key performance indicator.

| Downtime Factor | Gasketed Exchanger Risk | Welded Exchanger Solution |

|---|---|---|

| Component Failure | High (Gasket degradation) | Low (No gaskets to fail) |

| Maintenance Type | Reactive (Emergency repairs) | Proactive (Minimal inspection) |

| Production Impact | Significant (Lost batches, missed targets) | Minimal (Sustained operation) |

Critical cooling loops, continuous chemical reactions, and power generation facilities cannot afford unexpected shutdowns. The inherent reliability of the welded design protects these vital processes and ensures production goals are met consistently.

Prioritizing Long-Term OPEX Over CAPEX

A smart financial strategy looks beyond the initial purchase price (CAPEX) and considers the total cost of ownership over the equipment's life. This includes operational expenditures (OPEX) like maintenance, energy, and downtime costs. A fully welded plate heat exchanger is a strategic investment for organizations focused on reducing long-term OPEX.

The financial justification is clear:

Zero Gasket Costs: Eliminates all expenses related to purchasing, storing, and replacing gaskets.

Lower Labor Costs: Frees up maintenance personnel by removing the need for regular gasket inspection and bolt tightening.

Sustained Energy Savings: Maintains high thermal efficiency without performance degradation, leading to lower energy consumption year after year.

An operator who prioritizes predictable, low operational costs will find the upfront investment pays for itself through these accumulated savings.

Applications with Limited Installation Space

Plant real estate is a valuable and often limited commodity. The high thermal efficiency of welded plate technology allows it to achieve a specific duty in a much smaller package compared to traditional shell and tube exchangers.

Space-Saving Advantage: This compact footprint is a decisive factor in several scenarios. Offshore oil and gas platforms, for example, have extreme space and weight restrictions. Retrofitting new equipment into existing, crowded mechanical rooms is another common challenge. The smaller size and lower weight of a welded unit simplify logistics, reduce structural support requirements, and make installation possible in tight envelopes where other technologies would not fit.

This design makes it an ideal solution for modular process skids, marine applications, and urban facilities where every square foot matters.

A fully welded plate heat exchanger represents a strategic investment, not just an expense. Its long-term returns in reliability, safety, and operational savings justify the initial outlay for challenging industrial operations. For applications where performance cannot be compromised, it is the superior and most cost-effective long-term choice.

FAQ

How does this unit compare to a shell and tube exchanger?

It offers higher thermal efficiency in a much smaller footprint. This design saves significant space and energy compared to older shell and tube technology.

Can a fully welded heat exchanger be cleaned?

Yes. Operators use a Cleaning-In-Place (CIP) process. This method circulates chemical solutions through the unit to dissolve fouling and restore performance without any disassembly.

What materials are common for these exchangers?

Engineers typically use stainless steel for construction. For highly corrosive applications, they select special alloys like Titanium, Inconel, or Hastelloy to ensure long-term durability.