Your 2025 Guide to Welded Heat Exchanger Advantages

Unmatched Reliability and Performance of a Welded Heat Exchanger

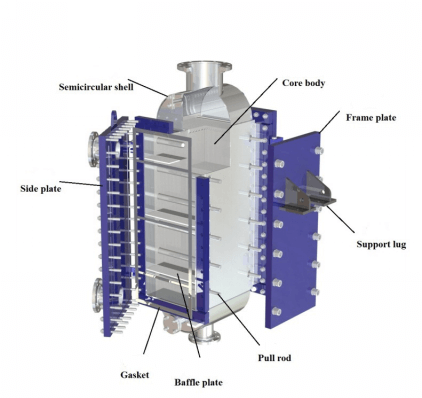

A system's reliability is the foundation of its value. A welded heat exchanger offers robust construction that ensures consistent performance, even in the most challenging operational environments. This design philosophy directly translates to greater operational stability and peace of mind.

Eliminate Leakage and Downtime

Traditional heat exchangers often rely on gaskets to seal the plates. These gaskets can degrade over time, leading to leaks, process fluid contamination, and unplanned shutdowns for repairs. The all-welded design completely removes this point of failure.

The absence of gaskets in a welded heat exchanger creates a fully sealed, contained system. This design inherently prevents leaks, protecting both your process and the environment. 🛡️

This leak-proof integrity is critical for handling aggressive or hazardous fluids. It also means maintenance teams spend less time replacing worn-out components, which significantly boosts plant uptime and productivity.

Withstand Extreme Operating Conditions

Industrial processes frequently involve intense temperatures and pressures that can stress equipment to its limits. A welded heat exchanger is specifically engineered to thrive under these conditions. The robust, fully welded plates provide exceptional structural strength.

These units reliably manage:

·High Temperatures: They can operate at temperatures far exceeding the limits of gasketed models.

·Extreme Pressures: The welded seams create a durable pressure vessel capable of handling significant force without risk of failure.

·Thermal Cycling: They withstand rapid temperature fluctuations that could cause fatigue and damage in lesser designs.

This resilience ensures the equipment maintains its performance and safety margins day after day.

Built for Demanding Industries

The combination of leak-proof operation and durability makes the welded heat exchanger an essential component in many critical industries. Its performance is not just an advantage; it is a requirement for safe and efficient operations. The table below highlights key industrial applications.

| Industry | Primary Application Benefit |

|---|---|

| Oil & Gas | Handles aggressive media and high pressures in refining and processing. |

| Chemical Processing | Provides safe containment for corrosive and hazardous chemicals. |

| Power Generation | Withstands high temperatures in steam cycles and cooling systems. |

| HVAC & Refrigeration | Offers a compact, efficient solution for large-scale ammonia-based systems. |

These sectors choose this technology because it guarantees the operational security and efficiency needed to meet stringent production and safety standards.

Superior Efficiency and Long-Term Cost Savings

Beyond its robust construction, a welded heat exchanger delivers significant financial benefits through superior efficiency and reduced operational expenses. These advantages make it a smart investment for any forward-thinking operation.

Maximize Thermal Efficiency

High thermal efficiency is a core feature of this technology. The design promotes exceptional heat transfer, which directly translates to lower energy consumption and reduced operating costs. Several factors contribute to this high performance:

·Corrugated Plates: The plates have specially designed patterns that create turbulent flow, even at low flow rates.

·Turbulent Flow: This turbulence maximizes contact between the fluid and the plate surface, dramatically increasing the heat transfer coefficient.

·Thin Plate Material: The thin metal plates offer very little resistance to thermal transfer, allowing energy to move quickly and efficiently from one fluid to the other.

This design allows a welded heat exchanger to achieve the same thermal duty as a much larger, less efficient unit.

Reduce Fouling and Cleaning Needs

Fouling, or the buildup of unwanted deposits on heat transfer surfaces, is a common problem that degrades performance and increases maintenance costs. The engineered plate design actively combats this issue.

The high fluid turbulence acts as a self-cleaning mechanism, scrubbing the plate surfaces to prevent deposits from settling. This keeps the unit running at peak efficiency for longer periods. 🧼

This reduction in fouling means fewer shutdowns are required for manual cleaning. Operations save significant time and resources that would otherwise be spent on labor, chemicals, and equipment downtime.

Lower Total Cost of Ownership

Total Cost of Ownership (TCO) provides a complete picture of an asset's lifetime cost. A welded heat exchanger excels in this area by minimizing expenses across its entire operational life. The table below breaks down the key areas of savings.

| Cost Category | Savings Driver |

|---|---|

| Maintenance | No gaskets to replace; reduced cleaning frequency. |

| Energy | High thermal efficiency requires less energy for heating/cooling. |

| Operational | Increased uptime from superior reliability and less maintenance. |

| Installation | Compact size often reduces structural and piping costs. |

These combined savings result in a significantly lower TCO compared to traditional gasketed or shell-and-tube heat exchangers.

Achieve a Compact, Space-Saving Footprint

Plant floor space is a valuable commodity. The high efficiency of plate technology allows these units to be much smaller and lighter than other heat exchanger types with the same capacity.

This compact footprint offers tremendous flexibility. It allows for installation in tight spaces, reduces the need for heavy structural supports, and simplifies retrofitting projects. For offshore platforms, mobile systems, or crowded mechanical rooms, this space-saving design is a critical advantage. 🏗️

A welded heat exchanger is the definitive choice for reliability in demanding industrial environments. Its high thermal efficiency and minimal maintenance needs deliver significant long-term cost savings. This technology offers a clear strategic advantage for operations seeking to maximize performance and minimize downtime, making it a smart investment for 2025. ✅

FAQ

What makes a welded heat exchanger different from a gasketed one?

A welded heat exchanger uses fully welded plates instead of gaskets. This design creates a completely sealed, leak-proof system, enhancing reliability and preventing fluid contamination.

Can you repair a welded plate heat exchanger?

Yes, repairs are possible. Specialized technicians can address damage. However, their robust design significantly minimizes the need for frequent service compared to gasketed models.

Is a welded heat exchanger more expensive?

The initial investment may be higher. They provide a lower total cost of ownership through reduced maintenance, higher efficiency, and superior uptime. 💰