Is a Heat Exchanger Plate the Unsung Industry Hero?

What Makes a Heat Exchanger Plate a Hero?

Every hero has a core mission and a unique superpower. The heat exchanger plate is no different. Its effectiveness comes from a combination of its fundamental purpose and its brilliant physical design. This simple component executes its task with incredible efficiency, making it a true industrial champion 🦸.

The Mission: Precision Heat Transfer

The primary mission of a heat exchanger plate is to manage thermal energy. It facilitates the transfer of heat from a hot fluid to a colder fluid. The two fluids flow on opposite sides of the thin metal plate. They never mix. The plate acts as a highly conductive barrier, allowing heat to pass through it seamlessly.

This process requires extreme precision. In many industries, a deviation of even a few degrees can ruin a product or create a safety hazard. The plate's design ensures a controlled and predictable transfer of heat.

Why Precision MattersPrecise temperature control is not just about efficiency; it is about reliability and safety. It guarantees that food is pasteurized correctly, chemical reactions occur under stable conditions, and buildings maintain comfortable temperatures.

The Superpower: Maximizing Surface Area

The plate's true superpower lies in its deceptively simple design. It is not just a flat sheet of metal. Instead, each plate is pressed into a corrugated pattern, often resembling chevrons or a herringbone design. This clever engineering accomplishes two critical goals.

First, it dramatically increases the surface area available for heat transfer within a very compact space. More surface area directly translates to faster and more complete heat exchange.

Second, the pattern creates turbulence as the fluids flow across the plate. This turbulence forces the fluid to mix, preventing a stagnant layer from forming against the plate surface. This ensures that more of the fluid comes into contact with the plate, boosting transfer efficiency even further.

Here is a simple comparison:

| Feature | Flat Plate | Corrugated Plate |

|---|---|---|

| Surface Area | Low | High |

| Fluid Flow | Smooth (Laminar) | Turbulent |

| Efficiency | Poor | Excellent |

This combination of maximized surface area and induced turbulence allows plate heat exchangers to achieve superior performance while maintaining a small footprint.

The Hero's Anatomy: Types of Plates

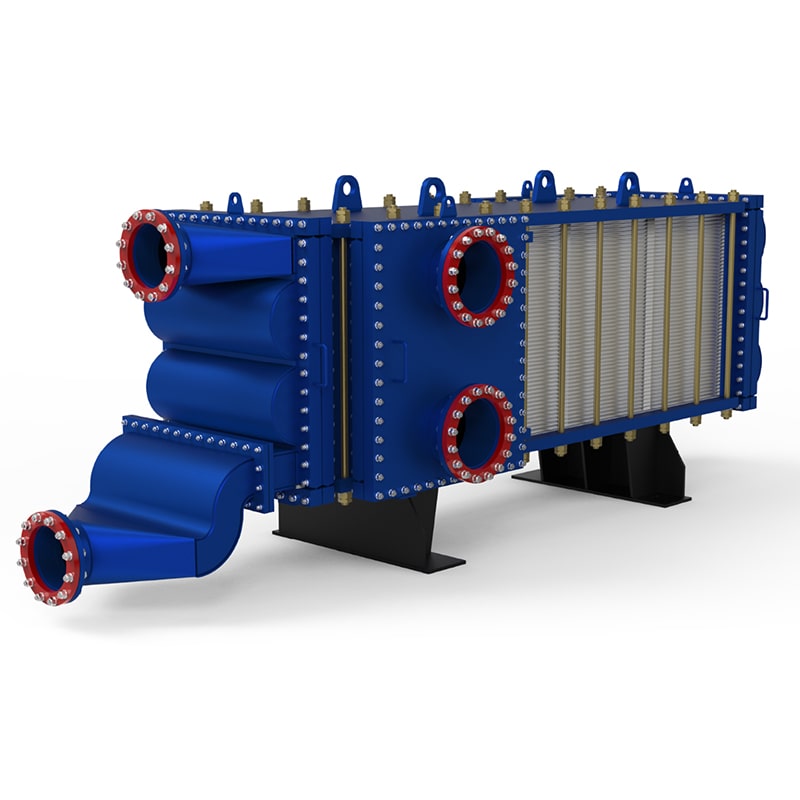

Not all heroes wear the same costume. Plate heat exchangers come in several designs, each tailored for specific operational demands. The three primary types are gasketed, brazed, and welded, each offering a unique combination of flexibility, durability, and performance.

Gasketed Plate Heat Exchangers

This is the most adaptable design. A gasketed unit consists of a series of individual plates held together in a frame. Rubber gaskets seal each heat exchanger plate and direct the fluid flow. This construction provides two major advantages:

·Flexibility: Technicians can easily add or remove plates to change the unit's capacity.

·Serviceability: The unit can be opened for easy cleaning and inspection, which simplifies maintenance.

This design is ideal for industries like food and beverage where frequent cleaning is necessary.

Brazed Plate Heat Exchangers

Brazed plate heat exchangers (BPHEs) offer a compact and efficient solution. In a BPHE, a stack of stainless steel plates is fused together using a copper or nickel brazing material in a high-temperature furnace. This process creates a permanently sealed, strong unit without the need for gaskets or a heavy frame. Their high thermal efficiency and leak-proof design make them a popular choice for refrigeration, air conditioning, and residential heating systems.

Welded Plate Heat Exchangers

Welded units provide the ultimate durability for extreme conditions. The plates in these exchangers are welded together, creating an incredibly robust and secure assembly. This design eliminates the need for gaskets, which can be a weak point with aggressive chemicals or at very high temperatures.

Built for Tough JobsWelded plate heat exchangers excel in demanding applications. They handle high pressures and temperatures found in chemical processing, oil and gas, and power generation industries.

Where This Hero Operates: Key Industries

This hero performs its mission across a vast landscape of critical sectors. Its ability to precisely control temperature makes it indispensable. Industries rely on this technology for safety, efficiency, and quality, proving its wide-ranging impact.

Food & Beverage: Ensuring Safety and Quality

The food and beverage industry depends on precise temperature control for public safety. Plate heat exchangers are essential for processes like pasteurization and sterilization. They rapidly heat and cool products like milk, juice, and beer. This quick thermal processing kills harmful bacteria without harming the product's taste or nutritional value. Key applications include:

·Milk Pasteurization

·Juice Sterilization

·Brewery Wort Cooling

·Yogurt Production

HVAC & Refrigeration: Delivering Comfort

Modern buildings achieve comfortable indoor climates thanks to this technology. In HVAC systems, plate units efficiently transfer heat between water circuits, providing heating in the winter and cooling in the summer. Refrigeration systems also use them as evaporators and condensers. Their compact size and high efficiency help reduce energy consumption, delivering comfort sustainably.

Chemical Processing: Enabling Critical Reactions

The chemical industry handles volatile substances and powerful reactions. Temperature control is a matter of safety and process viability. Plate heat exchangers manage the intense heat generated during chemical reactions. They maintain stable conditions, preventing dangerous temperature spikes.

These units allow chemical plants to run processes safely and efficiently. Their robust design handles aggressive fluids and high pressures, making them a trusted component in this demanding field.

Power Generation: Boosting Plant Output

Power plants must manage enormous amounts of heat to operate efficiently. Plate heat exchangers cool critical equipment like turbine oil and generator systems. They also play a role in waste heat recovery. Capturing this excess thermal energy improves the plant's overall output and reduces its environmental footprint.

The Hero's Toolkit: Why Plates Outperform

Every hero has a toolkit that gives them an edge. The plate heat exchanger's toolkit contains advantages that make it superior to older, bulkier technologies like shell-and-tube exchangers. These benefits explain why industries increasingly choose plates for their most critical thermal management tasks. The combination of efficiency, size, and serviceability creates an unbeatable value proposition.

Superior Thermal Efficiency

Plate heat exchangers achieve exceptional thermal performance. Their corrugated plates create a large surface area in a small volume. This design also promotes turbulent flow. The turbulence ensures that the fluid constantly mixes, allowing more of it to contact the plate surface for rapid heat transfer.

This high efficiency delivers tangible results. Plate units can transfer heat with a very small temperature difference between the two fluids. This capability, known as a close temperature approach, is crucial for processes requiring precise control.

The Efficiency Advantage 📈 Superior efficiency means less energy is needed to heat or cool a fluid. This directly lowers operational costs and reduces a facility's carbon footprint. It allows processes to run faster and more effectively, maximizing output while minimizing waste.

Compact and Adaptable Design

Space is a valuable commodity in any industrial facility. Plate heat exchangers offer a significant advantage with their compact footprint. A plate unit can provide the same thermal capacity as a shell-and-tube exchanger that is many times larger and heavier. This size difference frees up valuable floor space and simplifies installation.

| Feature | Plate Heat Exchanger | Shell-and-Tube Exchanger |

|---|---|---|

| Footprint | Small and compact | Large and bulky |

| Weight | Lightweight | Extremely heavy |

| Installation | Simple, often with minimal foundation | Complex, requires heavy lifting equipment |

| Flexibility | Easily expanded or reduced (gasketed) | Fixed capacity |

The design is also highly adaptable. Gasketed models allow engineers to add or remove plates to adjust the unit's capacity. This flexibility is invaluable for facilities with changing production demands. A single unit can be modified to meet new process requirements without needing a complete replacement.

Ease of Maintenance and Reduced Downtime

Downtime is a major expense in any industrial operation. The design of a gasketed heat exchanger plate unit minimizes this cost through simplified maintenance. Technicians can quickly open the unit by loosening the frame bolts. This provides immediate access to each individual plate for inspection, cleaning, or gasket replacement.

This process offers several key benefits:

·Fast Service: Cleaning and servicing are completed in a fraction of the time required for shell-and-tube units.

·No Specialized Tools: Most maintenance can be done with standard tools, reducing reliance on specialized contractors.

·Thorough Cleaning: Visual inspection ensures that all surfaces are completely clean, restoring the unit to optimal performance.

This ease of service translates directly to less downtime and lower labor costs. Plants can return to full operation faster, maximizing productivity and profitability.

The evidence confirms the heat exchanger plate is an unsung industrial hero. This component maximizes efficiency, ensures safety, and reduces costs for vital industries. It operates quietly, yet its impact is felt globally in the products we use and the energy we consume every day.

FAQ

How does a heat exchanger plate work?

It transfers heat between two fluids without mixing them. The fluids flow on opposite sides of a thin metal plate. This design allows thermal energy to pass through efficiently.

What is the main difference between plate and shell-and-tube exchangers?

Plate exchangers use corrugated plates for a large surface area in a compact unit. Shell-and-tube exchangers use tubes inside a large vessel, making them much bulkier and heavier.

Why are gasketed plates easy to maintain?

Technicians can easily open the unit to access each plate. This design allows for quick inspection and cleaning. It helps minimize operational downtime and simplifies service procedures.